Gearbox shell body inner hole polishing device

A gearbox and housing technology, applied in the field of gear box housing inner hole grinding device, can solve the problems of large workload, high labor intensity, and high operator requirements, and achieve the effects of improving work efficiency, reducing labor intensity, and cleaning the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

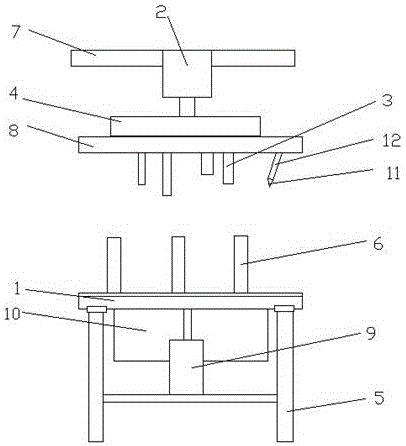

[0015] Such as figure 1 Shown, as the first embodiment of the present invention, a kind of gearbox housing inner hole grinding device comprises a workbench 1, a grinding motor 2, a grinding rod 3 and a gear box 4, and the bottom of the workbench 1 is provided with a support The legs 5 of the workbench 1, the workbench 1 is provided with a limit column 6, the grinding motor 2 is installed on the fixed frame A7 above the workbench 1, the motor shaft of the grinding motor 2 is connected with the gear box 4, several The two grinding rods 3 are installed in the mounting holes of the upper bracket B8, the bottom of the grinding rods 3 is connected with the rotating shaft of the gear box internal gear, and the bottom of the workbench 1 is connected with the cylinder rod of the cylinder 9, so that Chip removal holes (not shown) passing through the workbench are even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com