Business card rapid printing and manufacturing method

A production method and technology of business cards, applied in printing, typewriters, etc., can solve the problems of waste of printed matter, inaccurate cutting size, heavy manpower and material resources, etc., and achieve the effect of solving high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

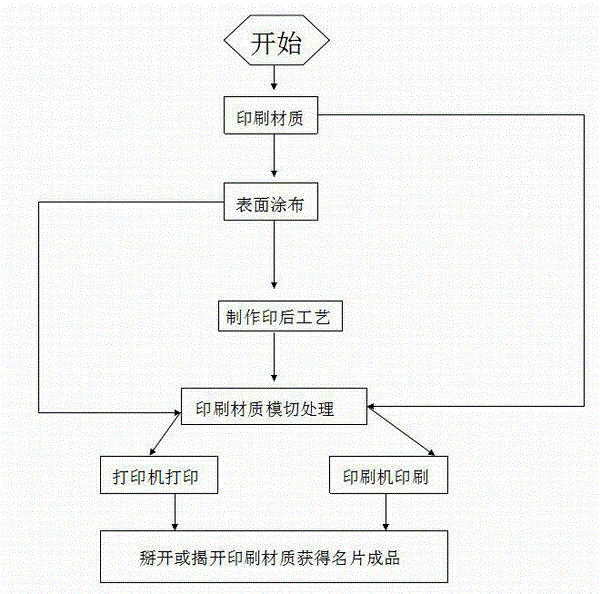

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0012] A method for quickly printing business cards, the specific steps are as follows: (1) Coating the surface of the printing material surface paper to obtain a coating, the raw material for the coating treatment is a pigment with a microporous structure or can form a porous The material with a permanent structure can achieve fast drying of ink droplets and good water resistance. The coating includes a glossy layer and an absorbing layer. The raw materials of the glossy layer include glossy pigments and additives. The glossy pigments are nano-silica, gas-phase method One or more of silicon and alumina, the raw materials of the absorbing layer include absorbing pigments and additives, the absorbing pigments are one or more of precipitated silica, special calcium carbonate and modified kaolin, the additives It is an adhesive, color fixing agent and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com