Maintenance module used for control components of water purifier and method for connecting maintenance module with filtering passage

A technology of control components and maintenance modules, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the workload of maintenance service personnel, increasing expenses, and complicating the maintenance process and other problems to achieve the effect of reducing maintenance service workload, simplifying maintenance difficulty and improving service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

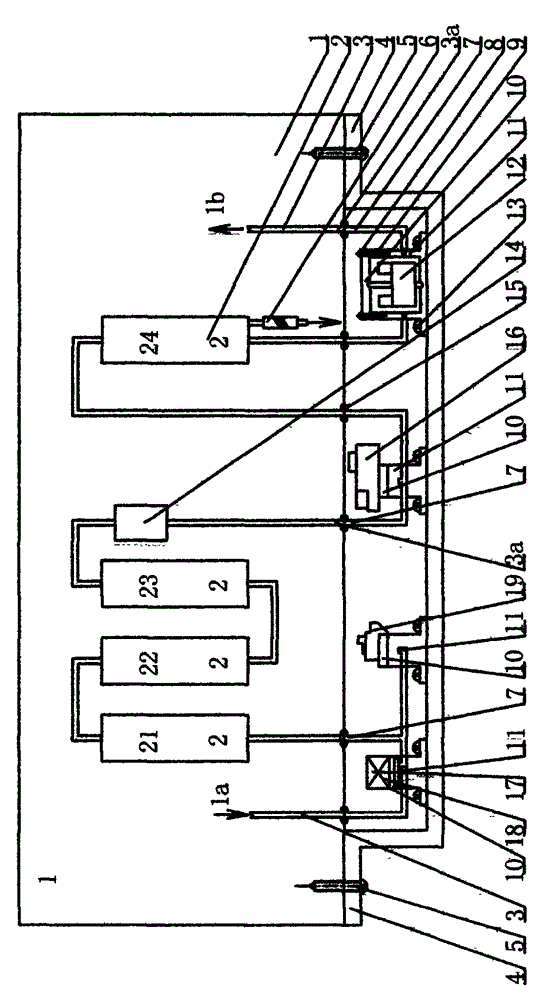

[0031] Example 1. Three pre-filters 21, 22, 23 are connected with RO reverse osmosis membrane filter 24 to form a pure water model, and a three-pipe pressureless faucet is used to control the water inlet pipeline of the machine, and the front end of the control valve is connected to the tap water pipeline , the water outlet at the rear end of the control valve is connected to the water inlet pipe interface 1a of the machine base 1, and the clean water outlet is connected to the water outlet pipeline interface 1b of the machine base 1. After the non-pressure faucet is closed, the filter channel 3 of the base 1 does not bear the pressure of the tap water pipe; after the non-pressure faucet is turned on, the water in the tap water pipe flows into the water inlet pipe 1a of the base, and passes through the filter channel 3 of the base 1. The same-direction docking water port 3a and the same-direction docking water port 7 on the maintenance module 4 trigger the low water pressure c...

Embodiment 2

[0041] Example 2. The water purification model is formed by connecting three pre-filter gallbladders 21, 22, 23 with the flow sensor 12, the ultraviolet sterilizer, and the water purification faucet. The flow sensor 12 arranged in the filter channel is used to control the driving of the ultraviolet sterilizer located in the water tank. When the clean water faucet is opened to lead through the filter channel, the flow sensor 12 operates to drive the ultraviolet sterilizer to sterilize the filtered clean water again. The flow sensor 12 and the ultraviolet sterilizer are arranged on the maintenance module, and at the same time, the butt pipeline corresponding to the flow sensor 12 and the ultraviolet sterilizer is set on the maintenance module, and a butt pipeline can be set up to connect the sensor 12 and the ultraviolet sterilizer in series. , and set two same-direction docking water ports 7, which are sealed and docked with the two same-direction docking water ports 3a corres...

Embodiment 3

[0042] Example 3. On the basis of the four modes in Embodiment 1, the concentrated water flow control device connected to the concentrated water outlet of RO reverse osmosis membrane filter gall or NF nanofiltration membrane filter gall 24 is also arranged on the maintenance module 4 . At the same time, on the maintenance module, a docking pipeline corresponding to the flow control device of the concentrated discharge water is provided, and a butt joint water port 7 in the same direction connected to the water inlet pipeline of the flow control device 6 of the concentrated discharge water can be installed, and the RO reverse osmosis membrane on the machine base 1 One co-direction butt joint water port 3a at the corresponding place of the concentrated water outlet pipeline of the filter tube or NF nanofiltration membrane filter tube 24 is sealed butt joint; two co-direction butt joint water ports 7 can also be set to connect with the RO reverse osmosis membrane filter tube or T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com