Cavity-divided type blast furnace distributing device

A technology of distributor and blast furnace, applied in the field of metallurgical industry, can solve the problems of bearing and gear corrosion, dust accumulation of distributor, gas pressure fluctuation, etc., and achieve the effect of sufficient lubrication effect, reduction of manufacturing cost and low operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

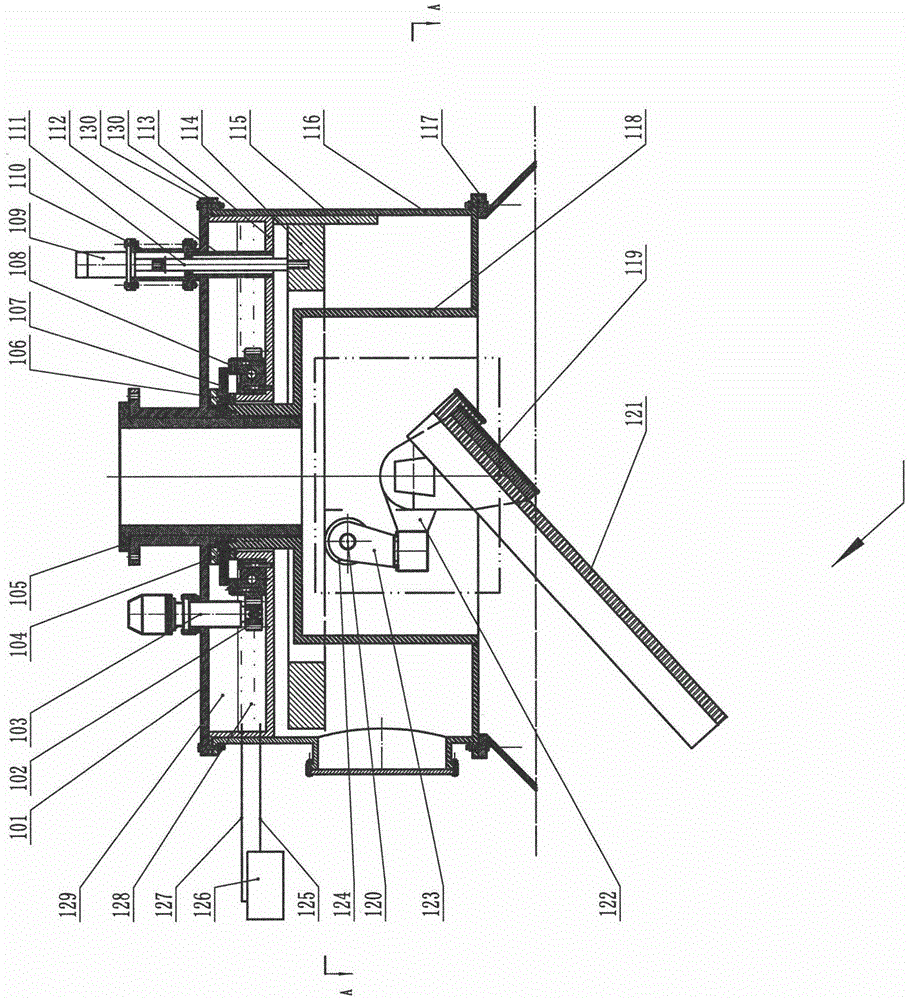

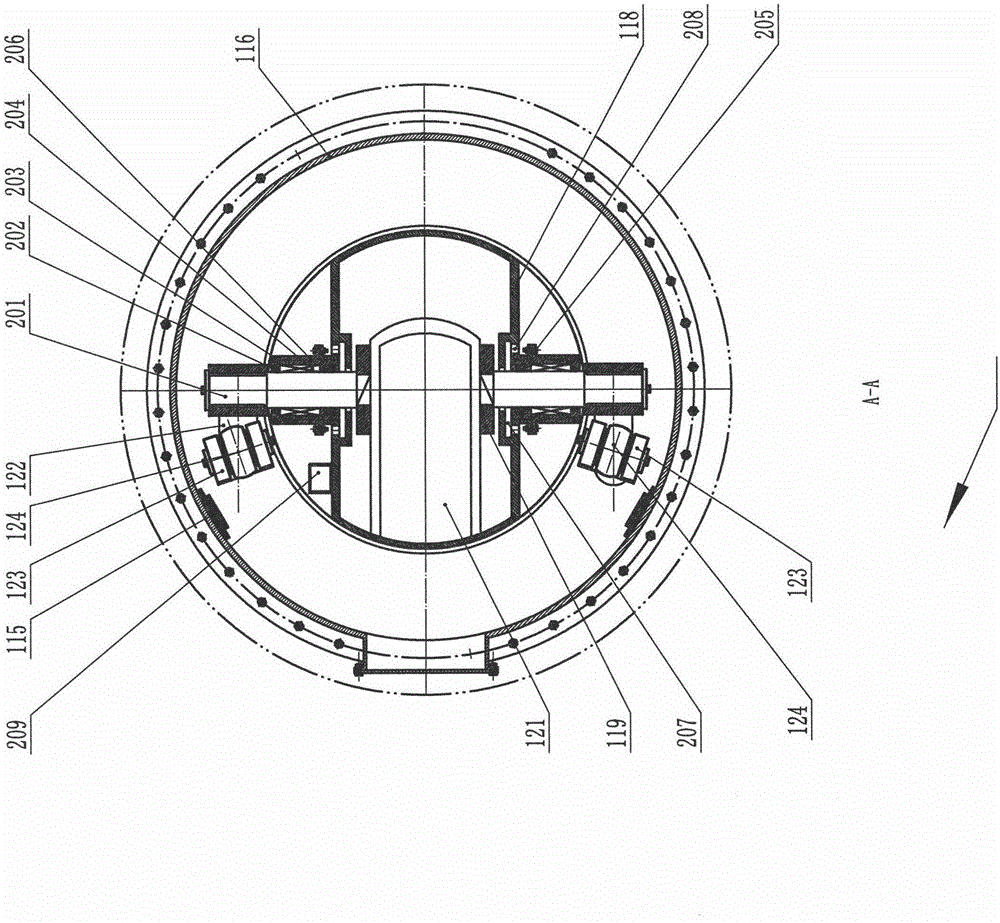

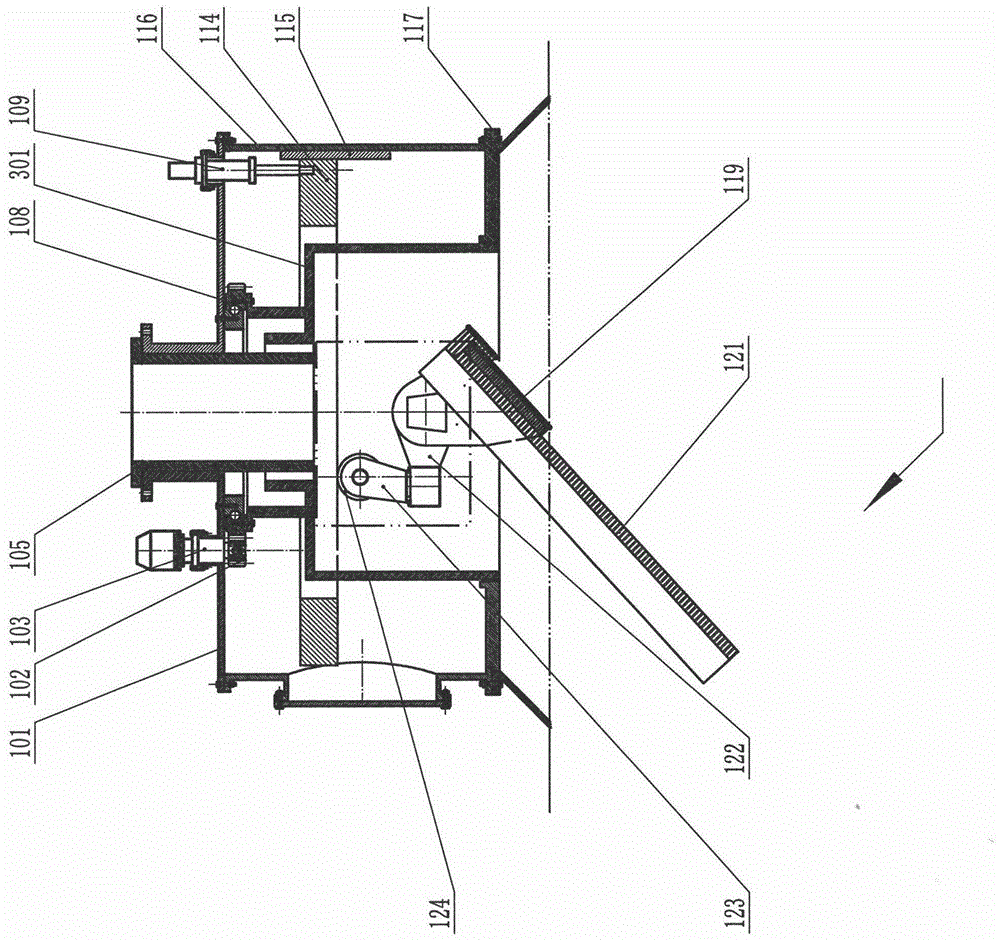

[0019] One example of the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The present invention solves the sealing and lubrication problems of the upper rotation support bearing (108), which involves the rotation of the drive chute (121) and the support of the rotating drum (118) in the distributor. organization. Regarding the transmission mechanism for controlling the inclination of the chute (121), the structure in the invention technology disclosed in the application number 201510140873.7 is adopted, and this part of the transmission mechanism will not be described in detail here.

[0020] figure 1 and figure 2 It shows the first embodiment of the invention of the sub-cavity blast furnace distributor. The box body (116) is horizontally installed on the furnace roof support ring (117), and the box cover (101) is horizontally installed on the box body (116). Motor and speed reducer (103) are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com