Production process of phosphorated high-strength gapless atomic steel

A technology of interstitial atom-free steel and production technology, applied in the manufacture of converters, etc., can solve the problems of high temperature drop rate, high difficulty, and small converter capacity, and achieve the effect of reducing temperature drop and stabilizing production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

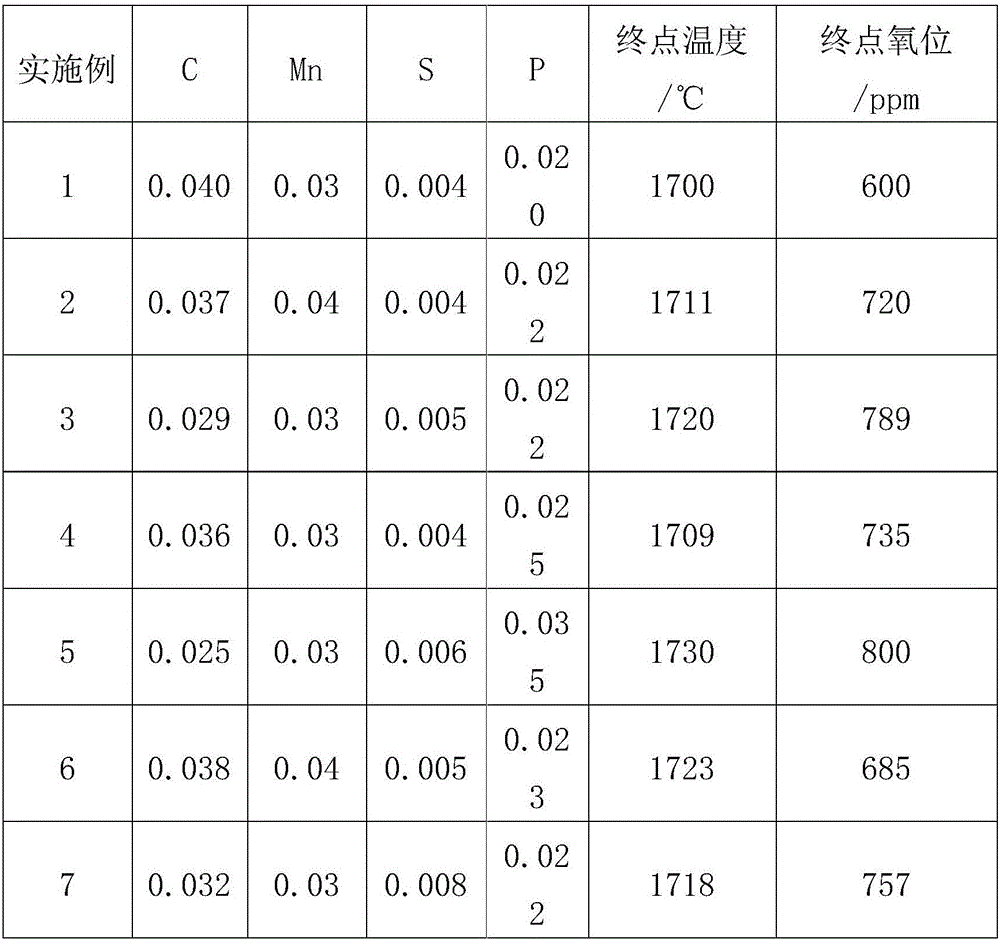

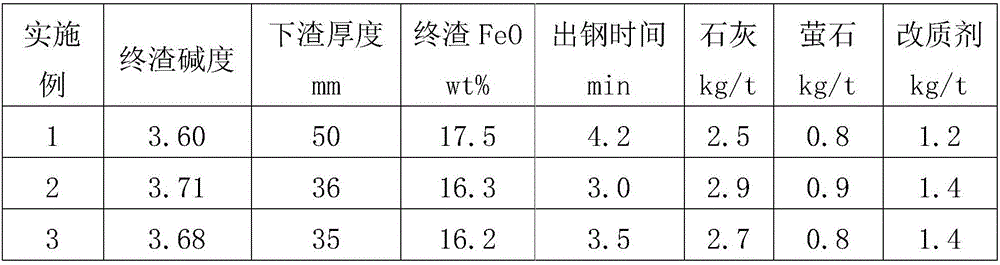

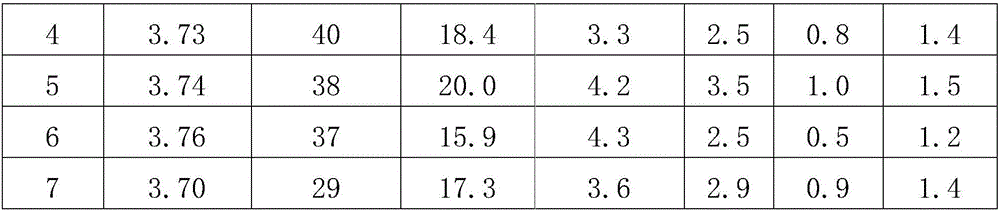

Embodiment 1-7

[0017] Embodiments 1-7: The production process of the phosphorus-added high-strength interstitial atom-free steel adopts the following process steps.

[0018] In Examples 1-7, a 100t converter and a 100t RH refining furnace were used for conventional slab continuous casting: continuous casting slab width 1100-1430mm, thickness 200mm, steel type TS250P1 steel was produced, and the process flow was: blast furnace molten iron → molten iron desulfurization → converter smelting →RH vacuum treatment→conventional slab continuous casting; the specific operation steps and process parameter control of each process are as follows; in the following processes, the full oxygen T.O≤20ppm and N≤30ppm of the molten steel in the tundish are controlled.

[0019] (1) Hot metal desulfurization process: After the ladle is sprayed with lime and magnesium powder, the slag is removed and desulfurized to S≤0.003wt%.

[0020] (2) Converter smelting process:

[0021] A. The temperature of molten iron en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com