Concrete distributing machine for bridge floor

A distributing machine and concrete technology, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high construction costs, high labor intensity of workers, uneven distribution, etc., to improve work efficiency, safe and reliable production and construction, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

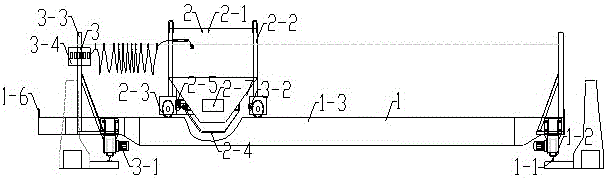

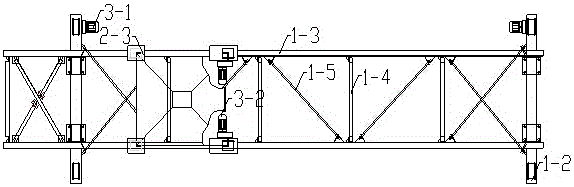

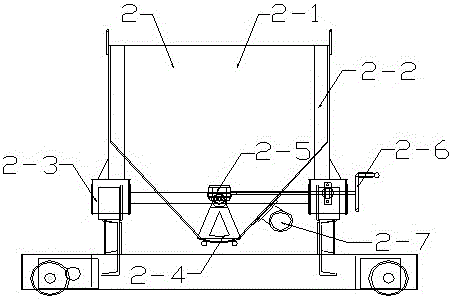

[0012] Embodiments of the present invention: first, design and process each component of the distributing machine according to the construction requirements of the bridge deck concrete pavement distributing materials. The walking part 1 is two electric end beams 1-2 and two transverse girders 1-3. The above electric end beams 1-2 are a steel box girder body with a longitudinal length of 2m and a transverse width of 0.18m and a height of 0.2m welded by steel plates. , two walking wheels are installed in the beam body, the wheelbase is 1.2m, and a soft-start complete machine brake motor 3-1 is installed on the outer side of a walking wheel in the beam body. The two electric end beams 1-2 are placed on the light steel rail 1-1, and the whole machine is driven to move along the bridge direction through the rotation of the whole machine braking motor 3-1; the transverse girder 1-3 is made of channel steel, Different types of channel steel are selected for the width of the surface c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com