Collapsible loess deep presoaked water dynamic compaction method

A technology of collapsible loess and pre-soaking water, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of long processing period and high processing cost, and achieve the effect of shortened construction period, reduced cost and broad application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

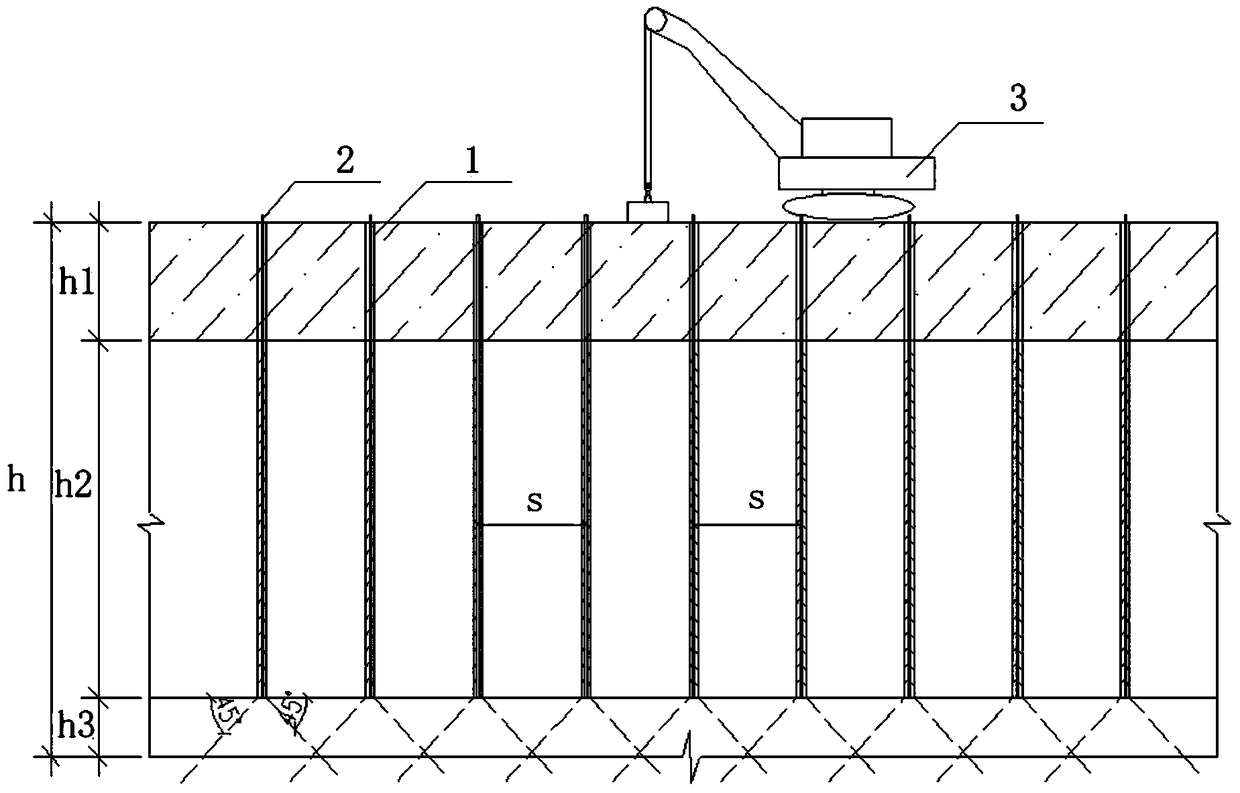

[0045] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

[0046] The core idea of the present invention is to solve the problem of processing the newly formed deep collapsible loess site or foundation of "digging mountains and filling valleys" encountered in a large number at present. According to the site building layout and use requirements, combined with the respective characteristics and advantages of pre-soaking water method and dynamic compaction method, which are common treatment methods for collapsible loess foundations, a set of comprehensive treatment technologies for deep collapsible loess sites or foundations has been formed by combining strengths and avoiding weaknesses. , effectively solve the problem of coordinated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com