Cast-in-place concrete flooring fine stone concrete pouring comprehensive complete equipment technical scheme

A complete set of equipment and cast-in-place concrete building technology, which is applied in the direction of construction, building structure, and building material processing, to achieve the effects of saving production costs, improving production efficiency, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

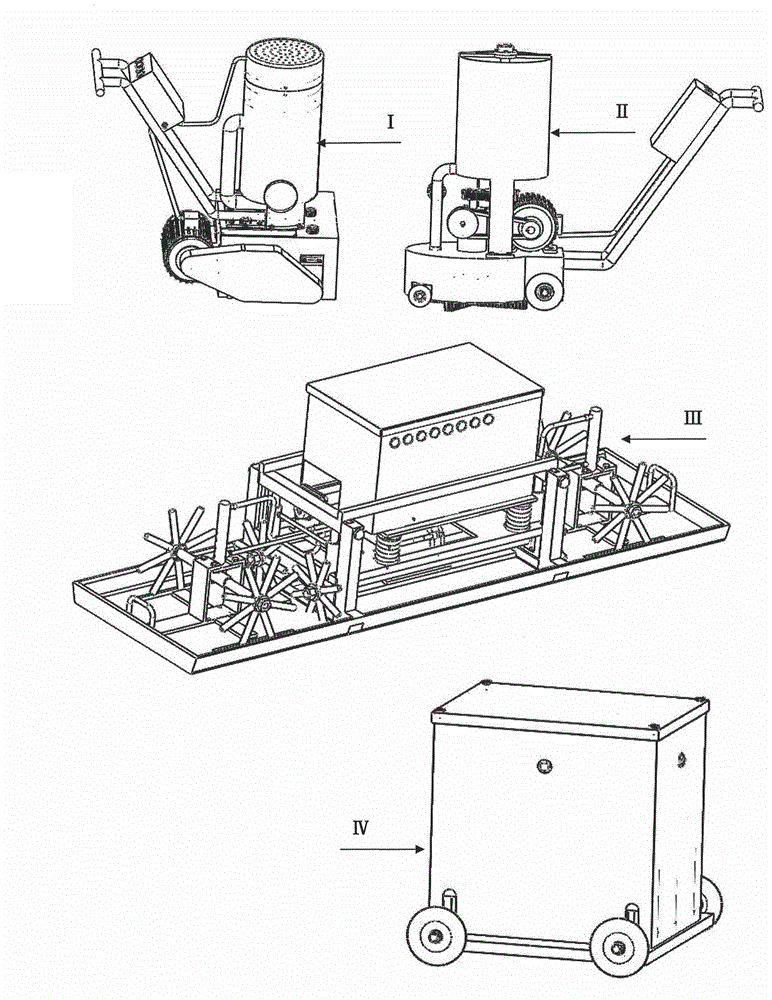

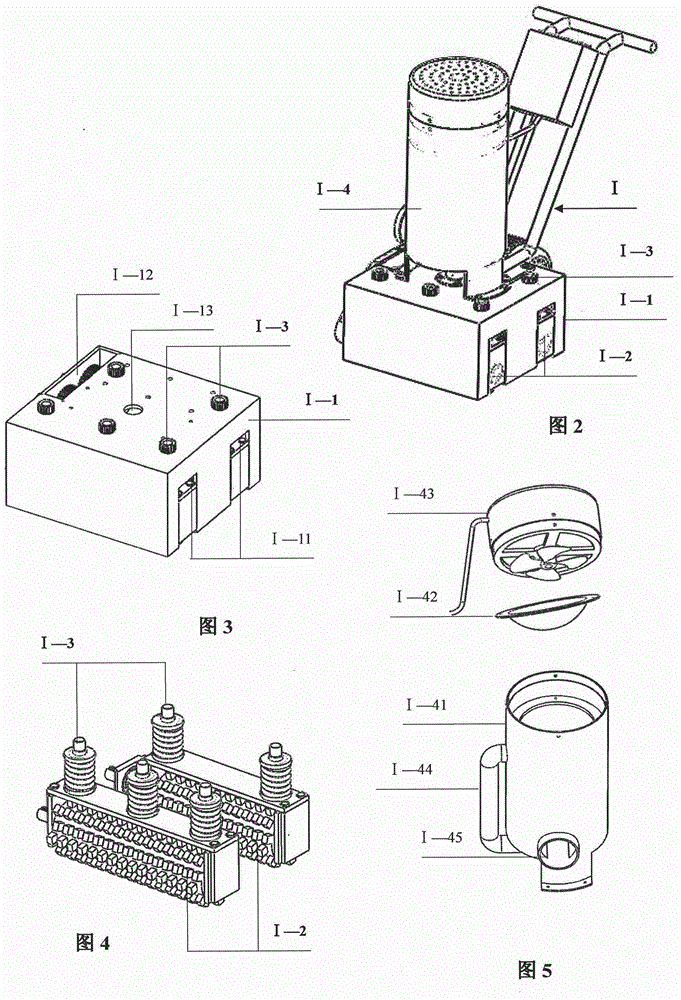

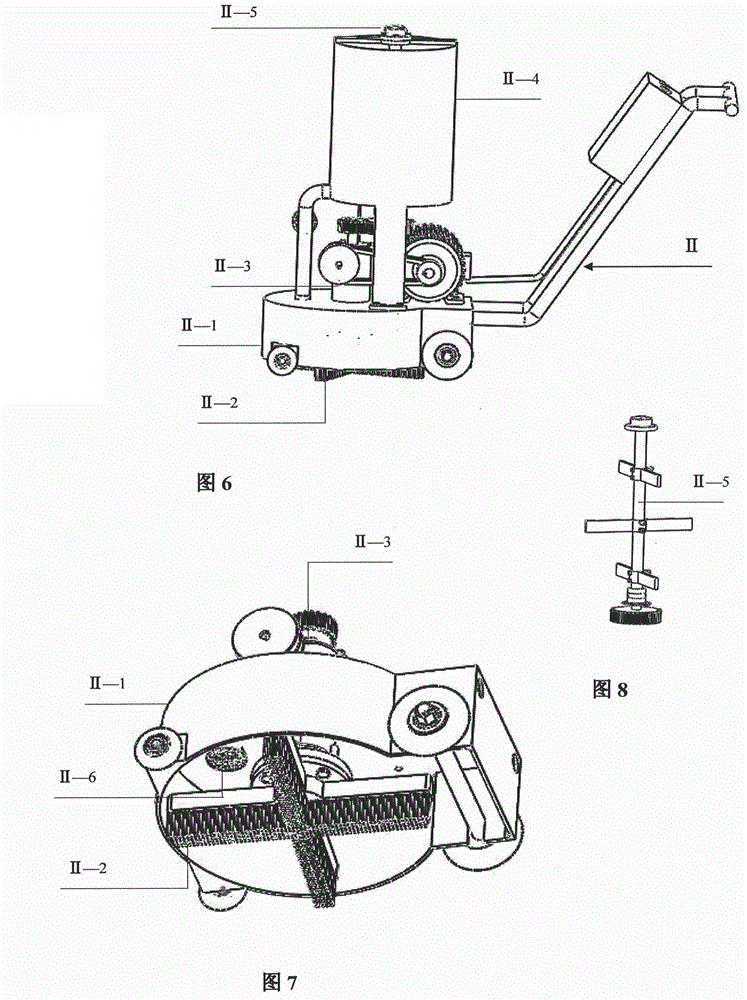

Image

Examples

Embodiment Construction

[0023] The concrete implementation method of the present invention is:

[0024] 1. Before pouring the fine stone concrete on the floor of the cast-in-place concrete floor, use a planer vacuum cleaner to clean the construction waste condensed on the floor of the floor to be poured, and then remove the large particles that have not been sucked by the vacuum device Clean up the construction waste, and then store water on the base of the building for more than 24 hours.

[0025] 2. Sweep and dry (dry) the pond on the building floor, mark the reference point corresponding to the elevation of the building floor according to the design requirements, fill the mixing bucket of the sweeper with water and turn on the mixing device, and slow down according to the design water-cement ratio requirements Slowly pour the cement into the bucket and stir. After stirring evenly, open the gate valve to spray the plain cement slurry and push the sweeper to sweep the slurry evenly.

[0026] 3. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com