Honeycomb chamfered composite plastic formwork

A composite plastic and chamfering technology, applied in the field of building materials, can solve the problems of high cost, heavy template weight, and insufficient turnover times, and achieve the effects of reducing weight, increasing strength, and easy construction and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

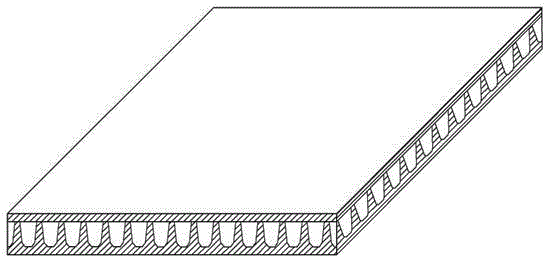

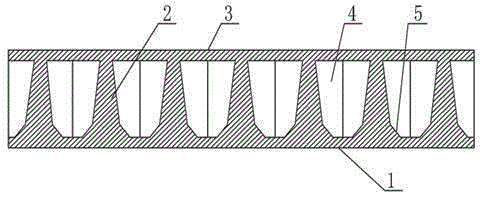

[0016] The base plate 1 is formed with the ribs 2 at one time.

[0017] The ribs 2 have a certain thickness and height, intersect vertically and horizontally, are connected end to end, and are in the shape of solid protrusions.

[0018] The panel 3 is combined with the large end faces of the ribs 2 .

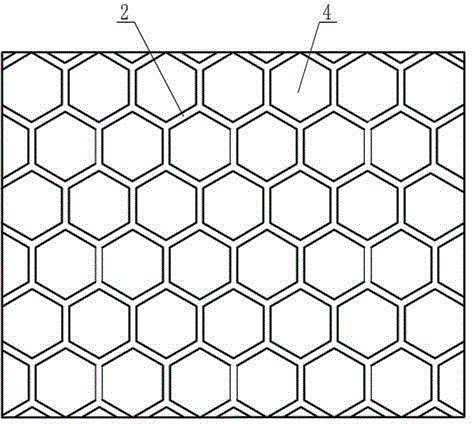

[0019] The honeycomb cavity 4 is an equilateral hexagonal pyramid cavity.

[0020] The transition chamfer 5 is that there is a transition bevel chamfering between the small end surface of the equilateral hexagonal pyramid cavity and the cone surface of the equilateral hexagonal pyramid cavity.

[0021] The cavity of the equilateral hexagonal pyramid is that the small end face is on the bottom plate 1 and the large end face is on the panel 3 .

[0022] The equilateral hexagonal pyramid cavities are each equilateral hexagonal pyramid cavity and six adjacent equilateral hexagonal pyramid cavities, the distance between the large end surface and the large end surface is equal, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap