Electronic component automatic measurement and storage system

A technology for electronic components and storage systems, applied in the field of measurement systems, can solve problems such as low efficiency, high error probability, calculation errors, etc., to save manpower, reduce error rate, and improve test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

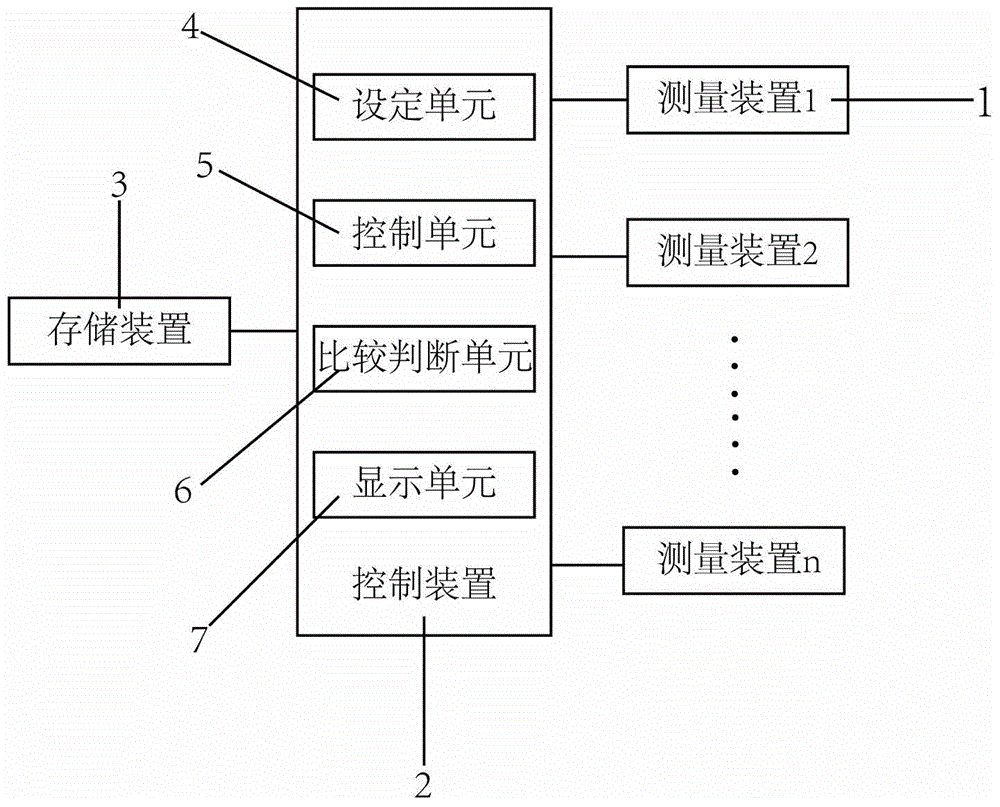

[0012] Such as figure 1 Shown is the schematic diagram of the patent of the present invention. The automatic measurement and storage system for electronic components described in the patent of the present invention is mainly used to measure whether different types of electronic components meet the specifications. The automatic measurement and storage system for electronic components described in the patent of the present invention mainly includes several measuring devices 1, control devices 2 and storage devices 3. The several measuring devices 1 are used to measure various types of electronic components. The control device 2 can be a computer, and the computer can be equipped with a GPIB industrial control card. The storage device 3 can be a background database server. The plurality of measuring devices 1 are used to measure the electronic components to be tested to obtain the actual electrical value of the electronic components to be tested, and the storage device 3 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com