Production method of full-dry big data photoelectric network cable and big data photoelectric network cable

A production method and big data technology, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of unprospected cable layout, no optical cable, large diameter of optical cable, etc., to reduce the bite of rodents capacity, improving construction efficiency, and increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

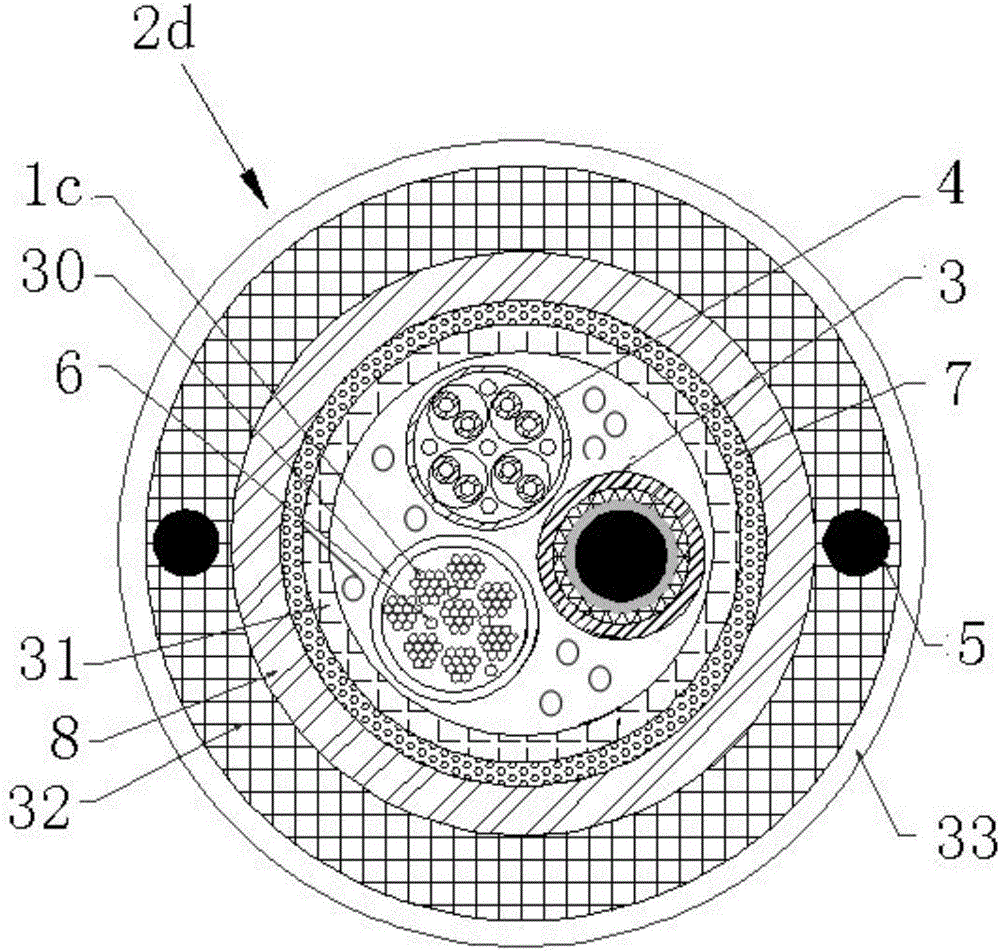

[0039] figure 1 Shown is the big data optical grid cable 2d made by the method of the present invention. The water blocking material 6 between the TV line 3, the network cable 4 and the optical cable 1c and the sheath 31 covering the TV line 3, the network cable 4, the optical cable 1c, and the water blocking material from the inside to the outside, and the water blocking material Belt 7, metal belt 8, two-layer sheath 32 and three-layer sheath 33, and wire 3 is embedded in the second-layer sheath 32. The optical grid cable 2d will be produced by the following method.

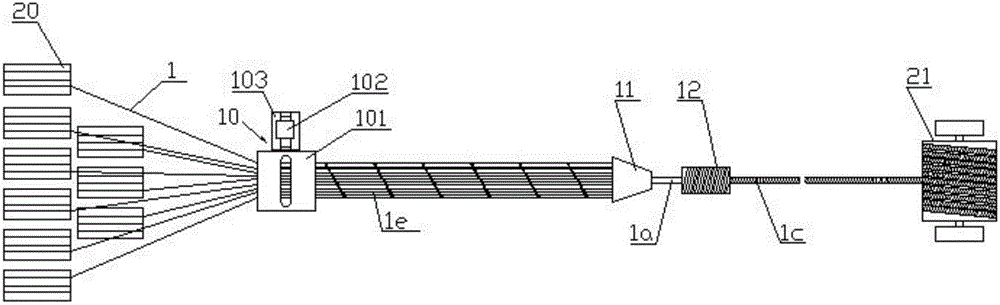

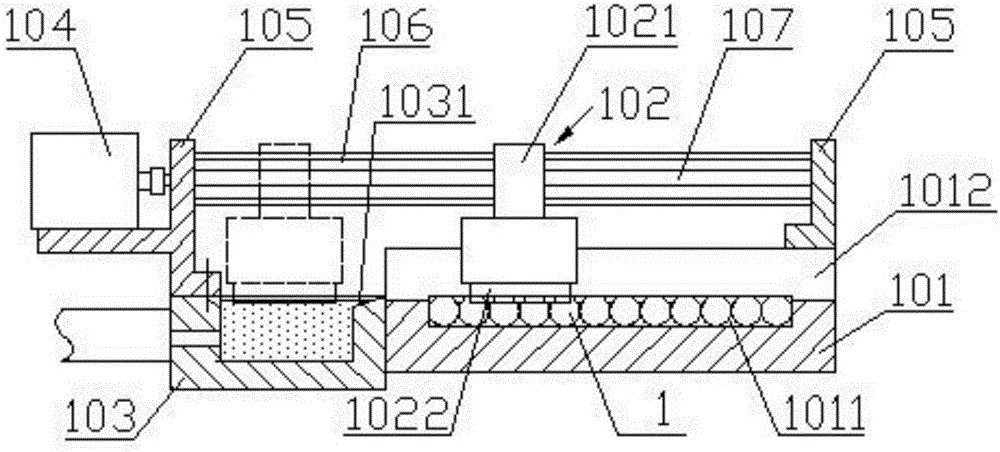

[0040] like figure 2 , 12 optical fibers 1 are released by the corresponding optical fiber pay-off machine 20 and run forward at a speed of 60-120 m / s. A parallel belt mold unit 10 is arranged on the running line, and several parallel parallel optical fibers 1 pass through the parallel belt The mold 10 controls the glue application frequency of the ribbon mold unit 10 to apply glue to the passing parallel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com