A monitoring method for coal consumption and carbon emission in a cement plant

A cement plant, carbon emission technology, applied in energy management and energy saving and emission reduction system, cement plant coal consumption and carbon emission monitoring field, can solve the problem that industrial quantity cannot be directly measured, energy saving and emission reduction restriction, and it is impossible to accurately monitor coal consumption and carbon emission in real time and other issues, to achieve the effect of improving the level of energy management, energy saving and emission reduction, comprehensive monitoring, and accurate and detailed data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

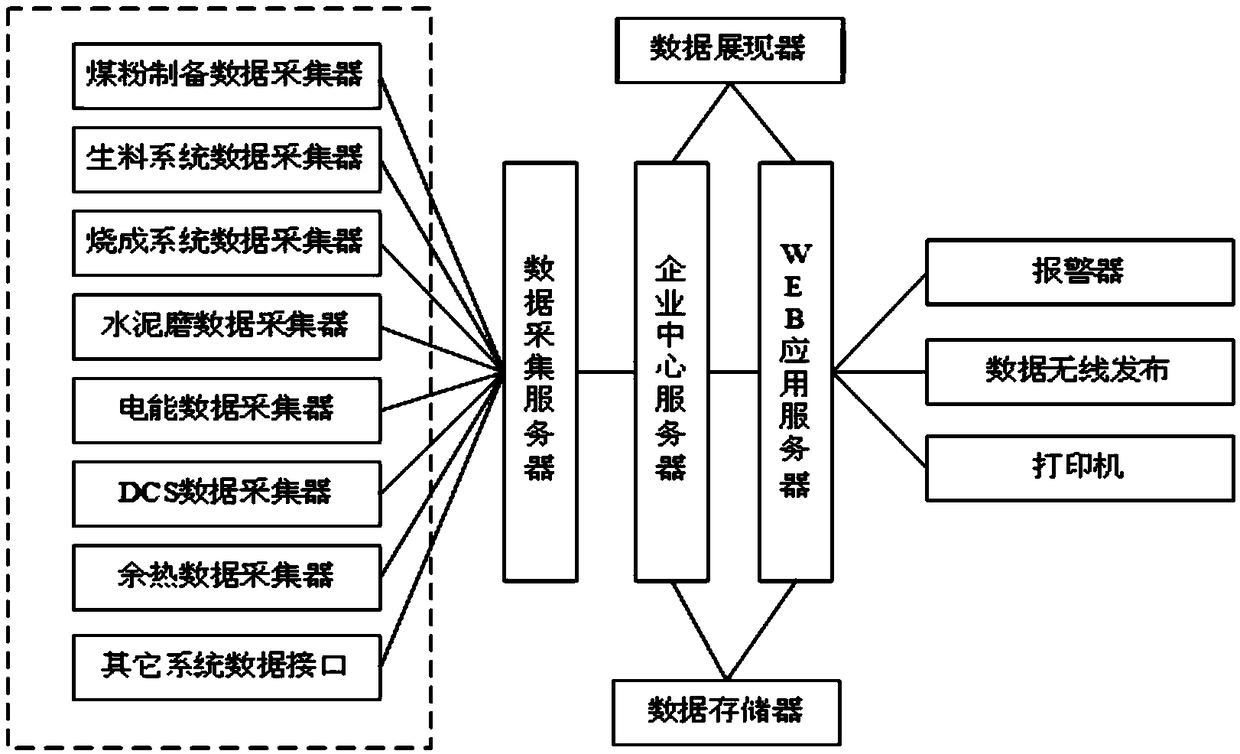

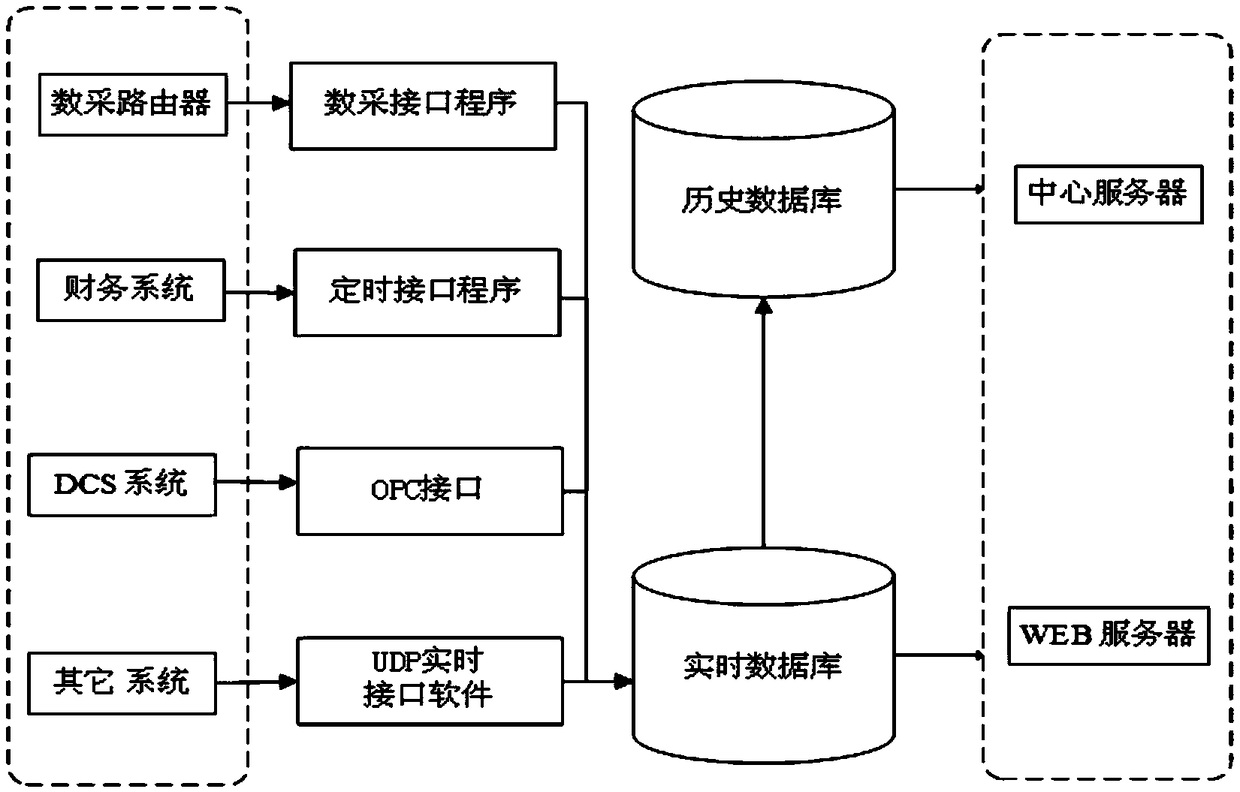

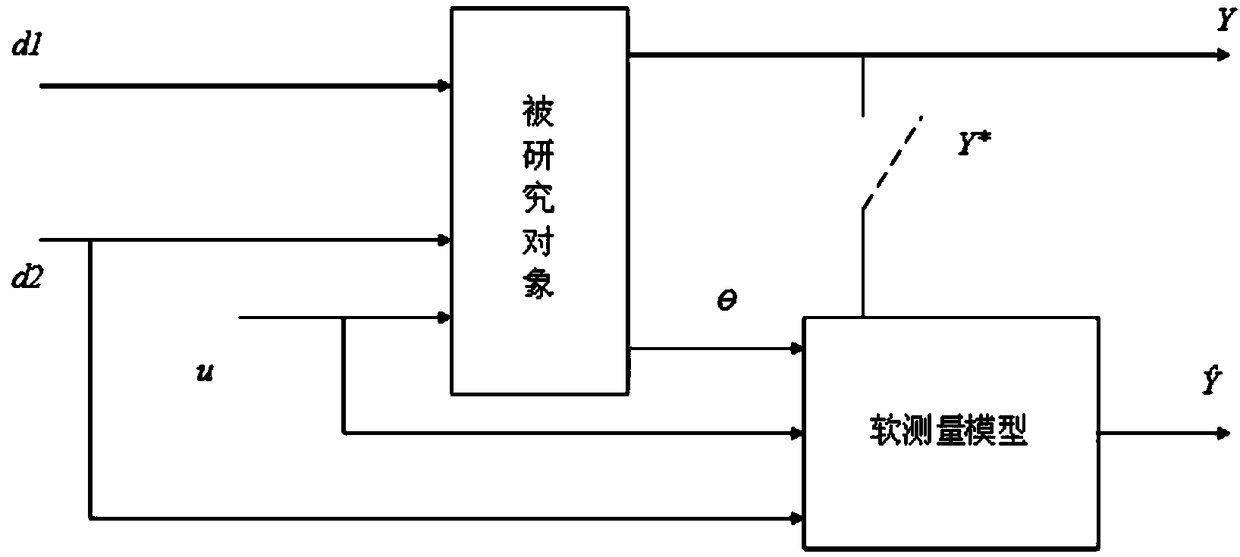

[0014] This embodiment provides a method for monitoring coal consumption and carbon emissions in a cement plant, such as figure 1 shown. The hardware part includes servers, on-site data collectors, metering sensors, temperature sensors, pressure sensors, flow sensors, composition analyzers, main servers, disk arrays, core switches, terminal computers, etc. The configured disk capacity of the main server guarantees that at least three years of historical data can be accessed online. The software part includes the four-in-one keying support platform, interface software, data acquisition and processing software, soft measurement calculation software, display software, wireless release software, etc.

[0015] The coal consumption and carbon emission monitoring method of the cement plant needs to collect and summarize all the data of the production system of the cement plant to calculate the coal consumption and carbon emission of the cement plant in real time. The production syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com