An air energy bga soldering station heating base

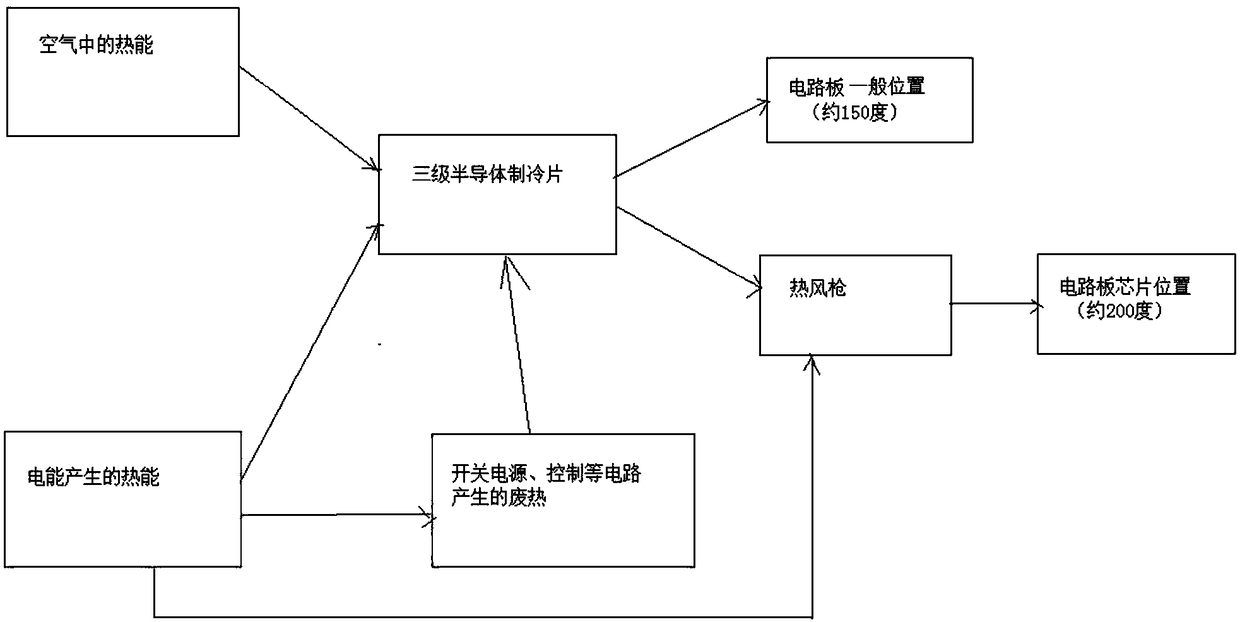

A heating base and air energy technology, which is applied in electrical components, circuit heating devices, printed circuit maintenance/calibration, etc., can solve the problems of large power consumption and waste heat of BGA rework stations, so as to reduce power consumption and waste heat emission , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

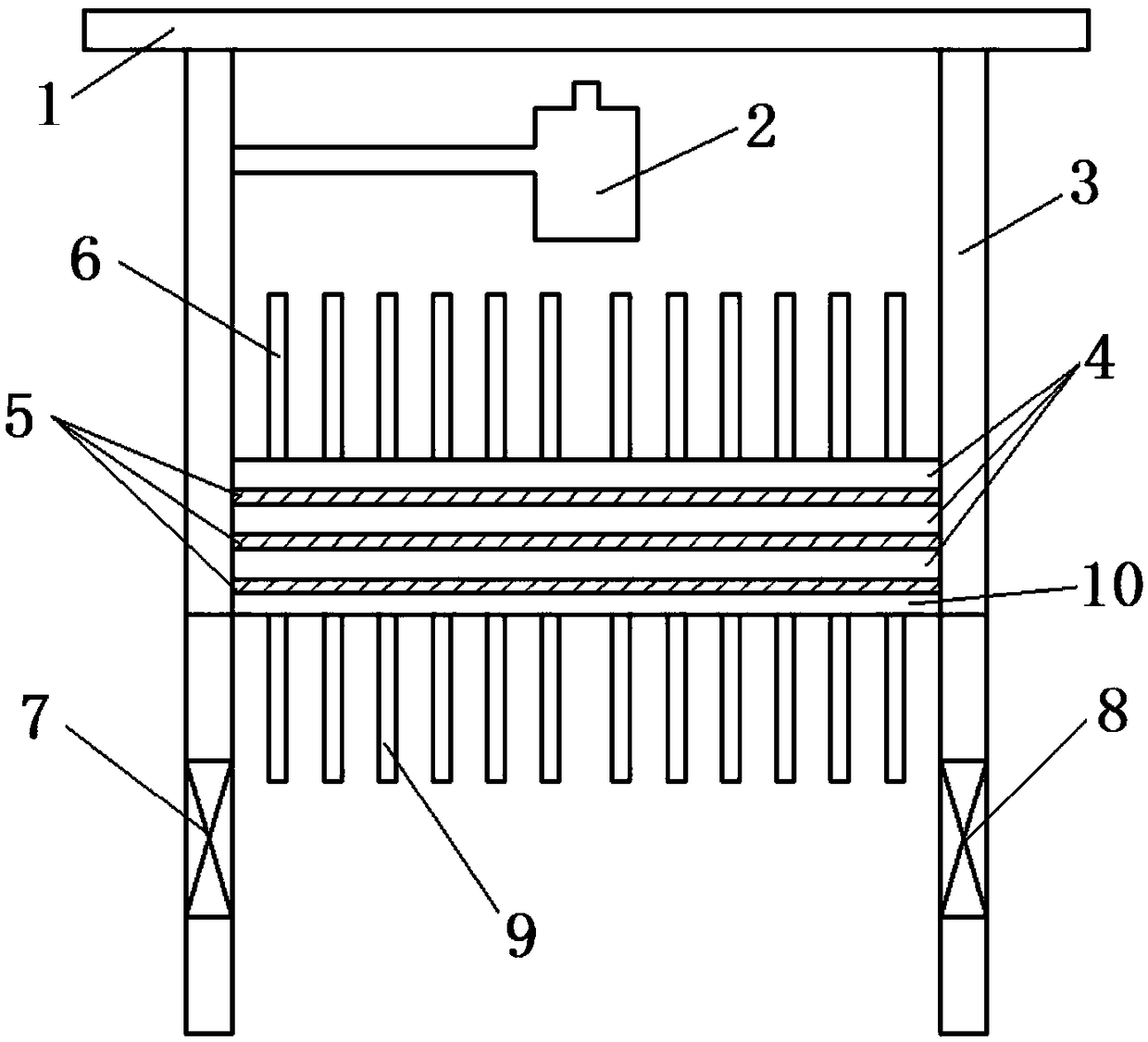

[0016] The technical solution of the present invention will be further elaborated below through an embodiment of a BGA soldering station with three temperature zones.

[0017] An air energy BGA soldering station heating base, including a base body 3, a base bottom plate 10 and a heat gun 2, and also includes a plurality of semiconductor cooling sheets 5 and a plurality of heat conducting copper plates 4, the first layer above the base bottom plate 10 is a semiconductor cooling sheet 5. The rest of the heat-conducting copper plates 4 and the semiconductor cooling sheets 5 are stacked alternately on the first layer of semiconductor cooling sheets 5, the uppermost layer is the heat-conducting copper plate 4, the cold ends of each layer of semiconductor cooling sheets 5 are consistent downward, and the heat gun 2 is installed at the bottom Above the upper heat conduction copper plate 4. The circuit board 1 to be soldered is located above the heat gun 2 .

[0018] It also includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com