Method and device for producing gear together with clamping means

A clamping mechanism and gear technology, applied in gears, applications, household appliances, etc., can solve problems such as the quality reduction of teeth, and achieve the effects of ensuring positioning, reducing production costs, and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

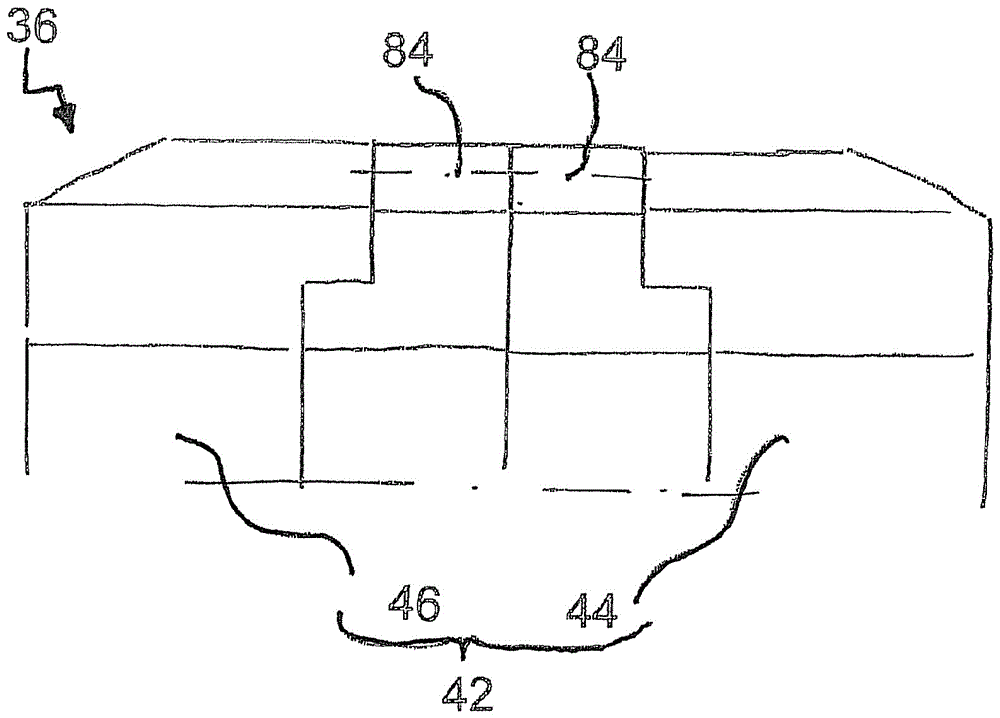

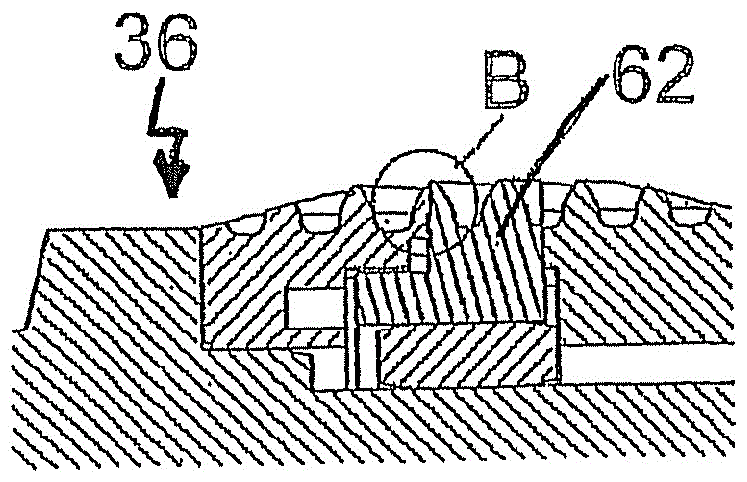

[0045] figure 1 An exemplary rolling device is shown schematically. The first rolling tool 10 with the first toothing 12 is rotatably supported in the direction of rotation 16 about the first axis 14. During rolling, the direction of rotation can be changed once or multiple times. The first rotational orientation may also be indicated in a direction opposite to that shown. The first tooth part 12 is in engagement with the second tooth part 18 of the gear blank 20. The gear blank 20 is rotatably supported around the second axis 22. Accordingly, the second direction of rotation 24 is formed. In addition, the second tooth portion 18 is in engagement with the third tooth portion 26 of the second tool 28. The second tool 28 is rotatably supported along a third rotation direction 32 about a third axis 30. With this type of rolling equipment, for example, in the area of machining allowance, at least the surrounding tools 10 and 28 having mating teeth 12 and 26 engaged in the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com