powdered binder

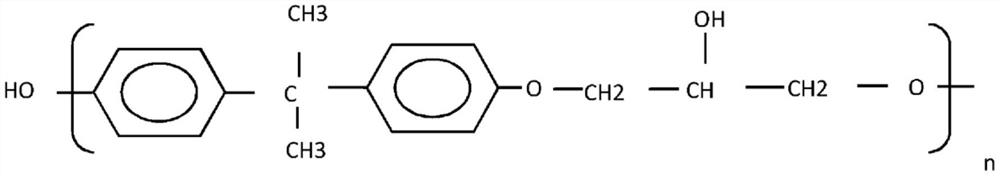

An adhesive and powder technology, applied in the field of powdered heat-activatable adhesives, can solve the problem of uneven distribution of adhesive particles, agglomeration of powdered adhesive particles, and adhesive adhesion of uneven strength. knots etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

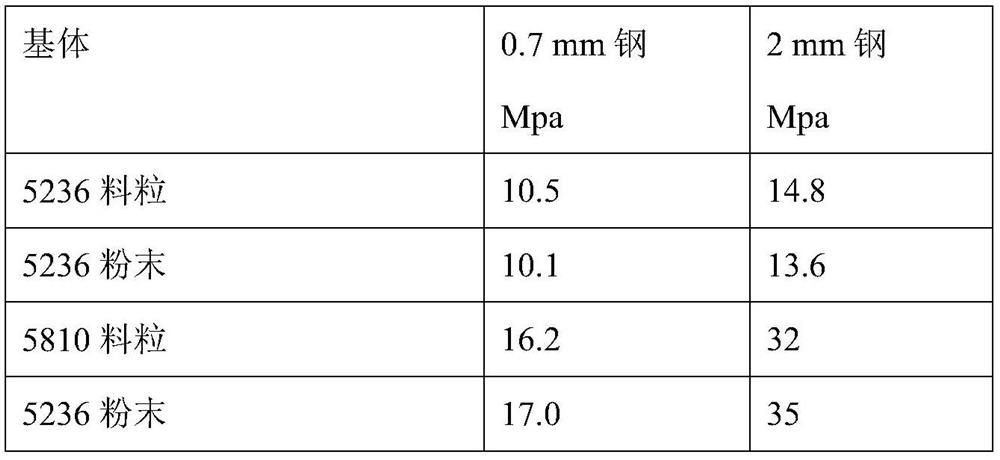

[0062] Code L5236 (foamable material) and L5810 (non-foamable material) from L&L Products as pellets available and with an average particle size of 1.5 to 3 mm were pulverized into a powder with an average particle size of about 0.3 mm.

[0063] The powder and stock pellets were applied to three flat test specimens of 0.7 mm and 2 mm thick galvanized steel, respectively.

[0064] The powder was applied by electrostatic spraying and the pellets by extrusion. Overlay another steel sheet on top of the adhesive and press the sheets together and hold at 165°C for 30 minutes. The T-peel strength of the resulting bond was measured as follows and the results are as follows.

[0065]

[0066] It was shown that the bonding performance was not significantly changed when extruded pellets or sprayed powder were used on flat steel sheets.

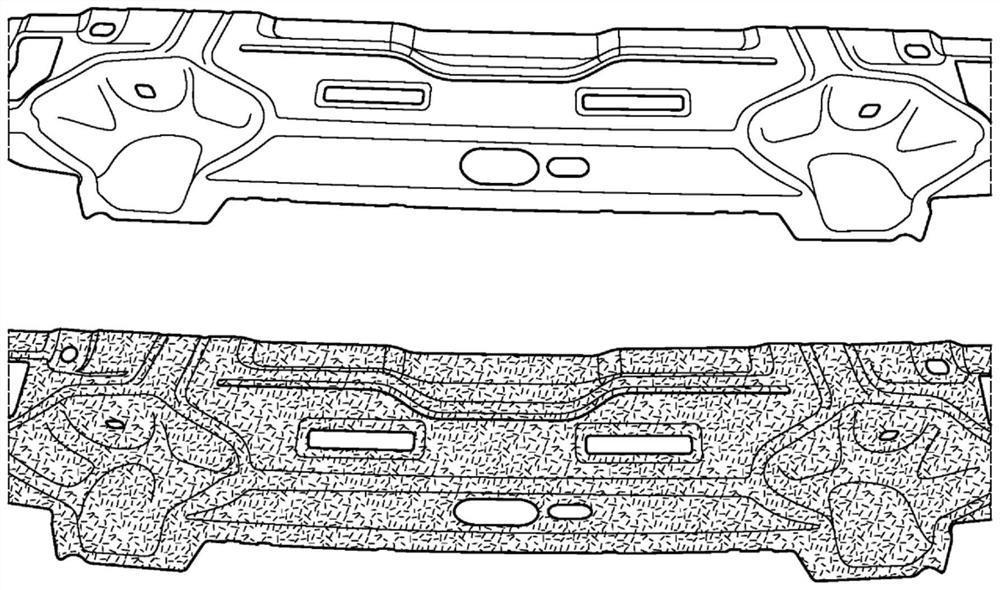

[0067] Then apply the adhesive to the figure 1 Auto parts shown in . Electrostatic spraying of powdered binder results in a uniform coating of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com