Composite fertilizer particle granulation apparatus

A technology of granulation device and compound fertilizer, which is applied to fertilization devices, fertilizer mixtures, solid/semi-solid fertilizers, etc., can solve the problems of rough surface of compound fertilizer particles, large equipment area, inability to form particles, etc., and achieve no irritation. Effects of sexual odor, increased productivity, improved particle appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

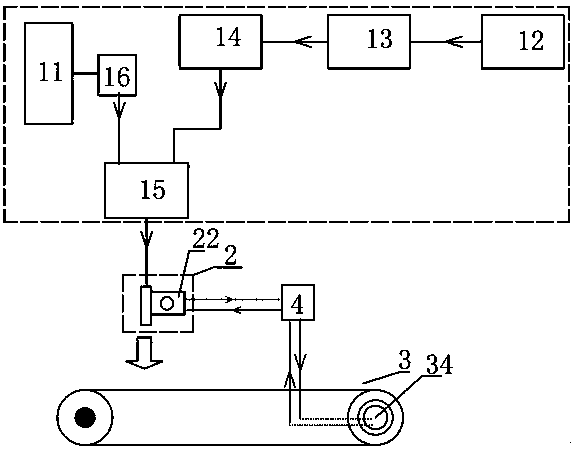

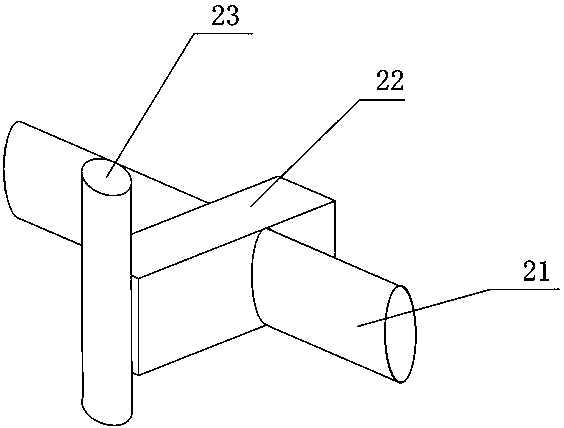

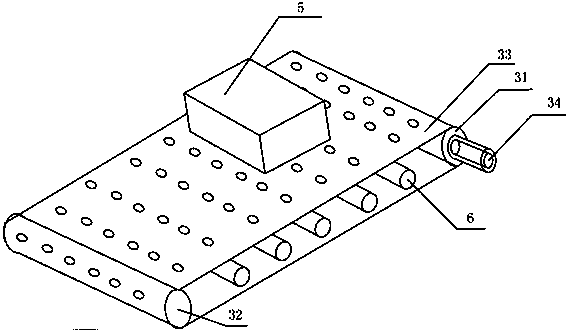

[0022] like figure 1 , a compound fertilizer granulation device includes a composite granule melting part 1, a granule forming part 2, and a rotary metal cooling conveyor 3:

[0023] Composite particle melting part 1 comprises pin ammonium phosphorus melting bin 11, auxiliary material mixing bin 12, auxiliary material crusher 13, heater 14, mixer 15, and described pin ammonium phosphorus melting bin 11 communicates with mixer 15 through pump 16, and auxiliary material The mixing bin 12 communicates with the auxiliary material crusher 13, the auxiliary material crusher 13 communicates with the heater 14, and the heater 14 communicates with the mixer 15. During operation, the ammonium phosphorus melting bin 11 is melted into a liquid, which is transported to the mixer 15 by a pump 16 In the process, the auxiliary materials of the compound fertilizer are pre-added in the auxiliary material mixing bin 12 to mix and cool, and then further crushed by the auxiliary material crusher 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com