Vertical slurry balance construction device

A mud-water balance and construction device technology, which is applied in infrastructure engineering, construction, caissons, etc., can solve problems such as inconvenient drainage, caisson crushing, and inconvenience, and achieve the effects of preventing instability and damage, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

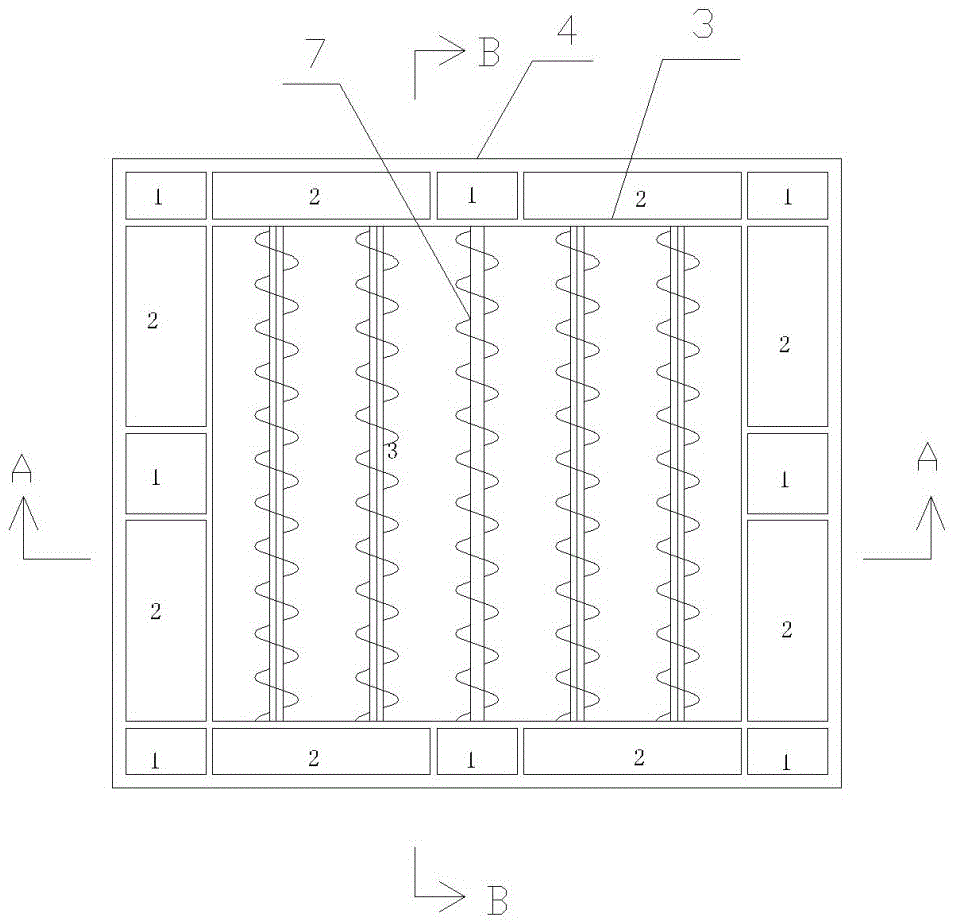

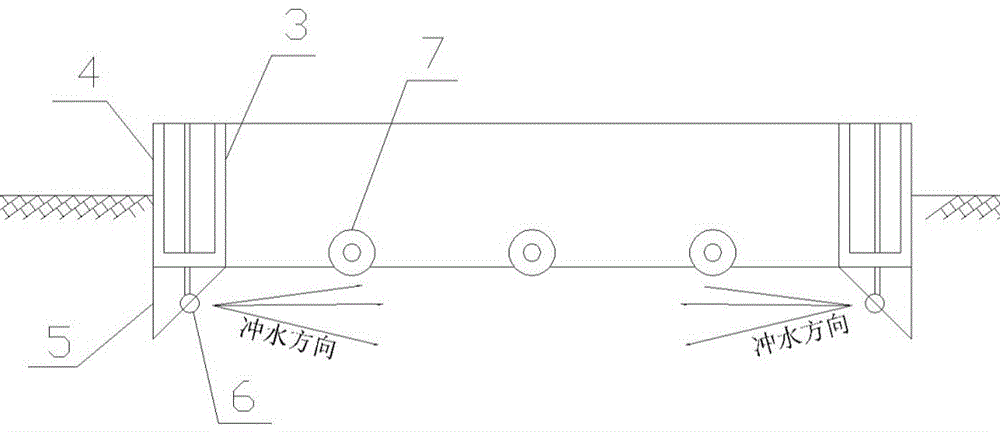

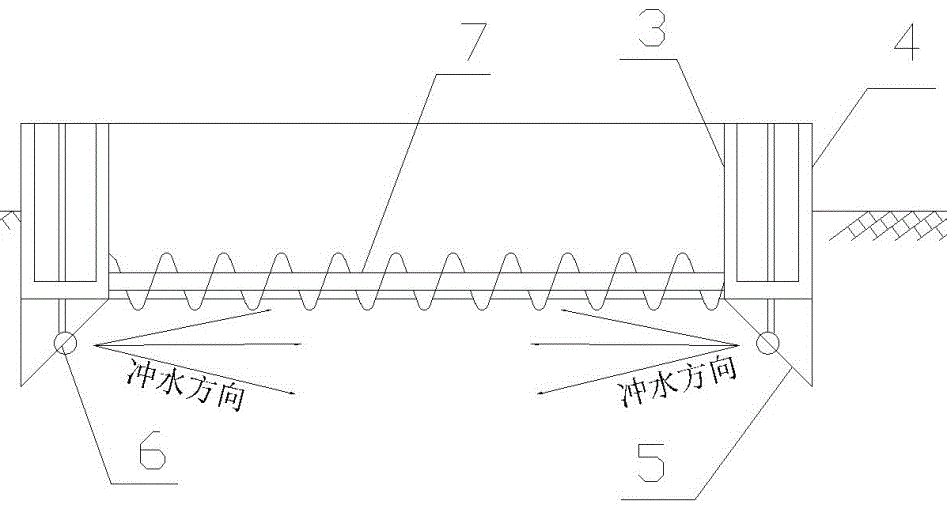

[0029] Such as figure 1 , 2 , Shown in 3, a kind of vertical mud-water balance construction device, it comprises caisson, caisson is rectangular, and caisson has double well wall. A water tank with a sealed bottom is formed between the inner well wall 3 and the outer well wall 4, that is, the bottom of the inner well wall and the outer well wall are connected together, and the gap between the inner well wall and the outer well wall in each direction is Two water tanks are isolated, a working well is isolated between the two water tanks, and a working well is also isolated at each corner of the rectangular caisson.

[0030] There is a blade foot 5 under the sealed bottom, and an independent blade foot is provided at the lower end of the well wall in each direction. The blade foot is a hollow triangular blade foot made of steel plate. A high-pressure water pump is installed inside each blade foot hollow. Of course, it can also be The pump is installed outside, and the high-pre...

Embodiment 2

[0035] Such as Figure 6 As shown, the difference from Embodiment 1 is that the blade foot is a triangular blade foot made of steel plate, one edge of the triangle bottom of the blade foot is connected to the bottom of the outer well wall through a hinge shaft 11, and the other edge is connected to the inner well wall. A hydraulic cylinder 12 that controls the rotation of the blade foot around the hinge shaft is arranged between them. In order to control the movement of the blade foot through the expansion and contraction of the hydraulic cylinder when the blade foot is stuck, and accelerate the downward movement of the caisson.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com