Variable speed drive and method for machining a variable speed drive

A technology of variable speed drive and action, which is applied to transmission parts, electromechanical devices, electric components, etc., and can solve problems such as reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

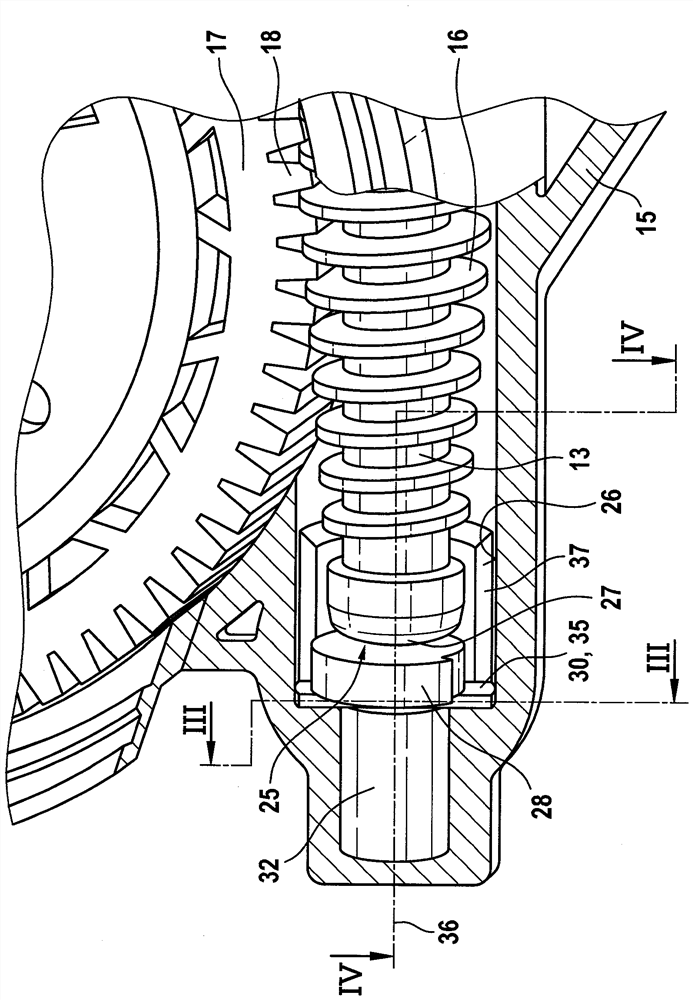

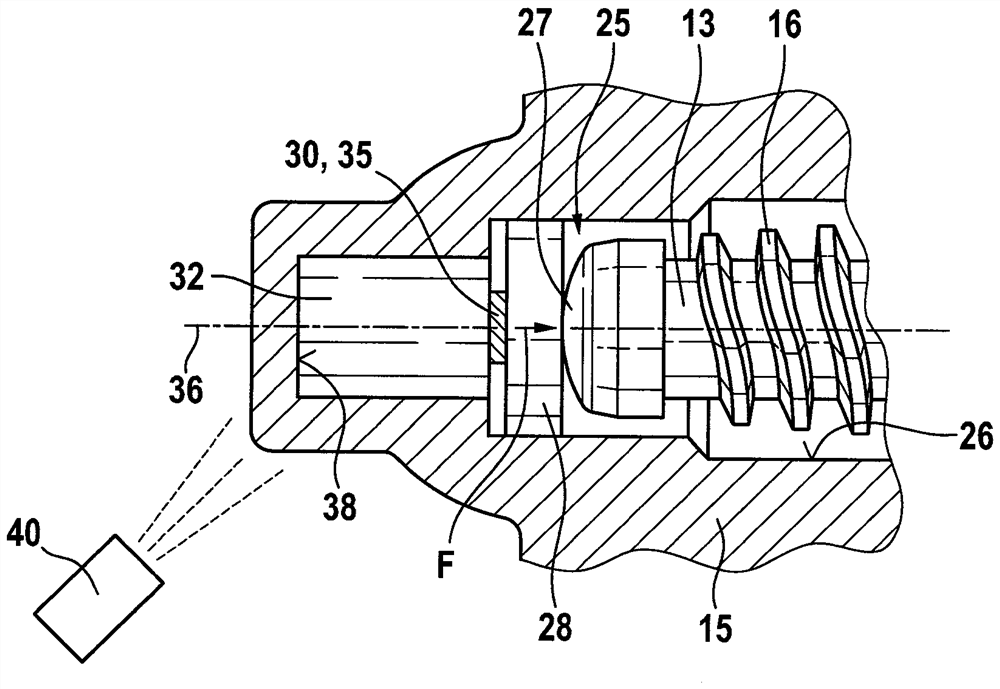

[0023] exist figure 1 The variable speed drive 10 shown in is a component of a convenience drive in a motor vehicle. A convenience drive is understood by way of example and without limitation to be a window lift drive, a sliding roof drive or the like, in which the element to be adjusted (window pane, sliding roof, etc.) is at least To move or manipulate indirectly.

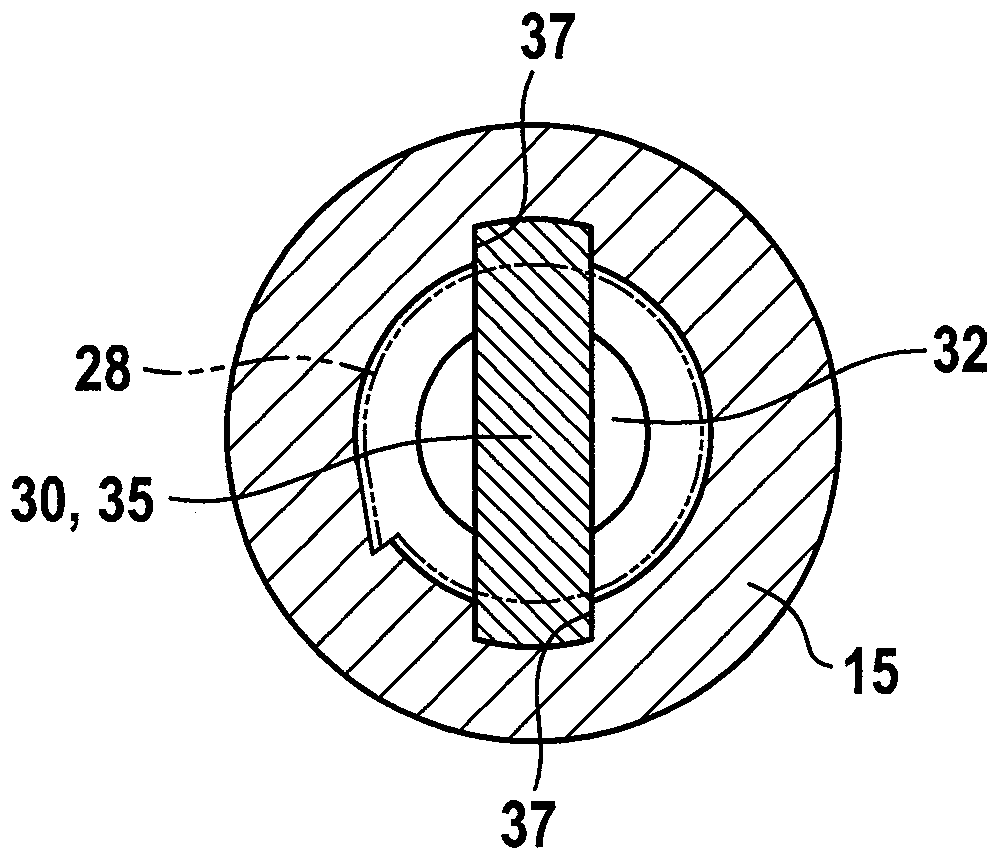

[0024] The variable speed drive 10 comprises an electric motor 12 arranged in a pole housing 11 , which protrudes via a section of an armature shaft 13 into a transmission housing 15 which is at least partially made of metal. The pole housing 11 is connected to the transmission housing 15 at the end in a conventional manner, for example by screwing.

[0025] The armature shaft 13 has, inside the transmission housing 15 , a toothing 16 designed as a helical toothing or a screw toothing, which meshes with a mating toothing 18 formed on the circumference of the spur gear 17 . The spur gear 17 is mounted rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com