Precision measuring device based on circularity cylindricity and measuring method thereof

A precision measurement and cylindricity technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as inability to move, poor interface friendliness, poor user experience, etc., to improve transmission efficiency and stability, facilitate debugging of instruments, and stabilize instruments good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

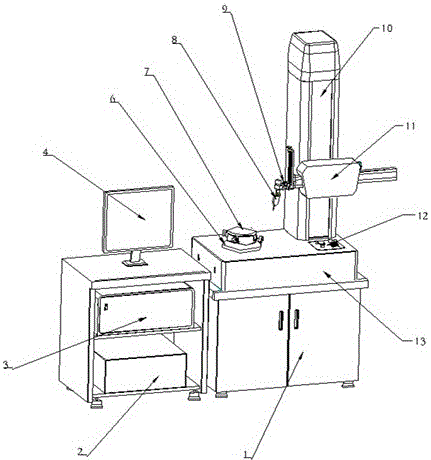

[0019] like figure 1 , figure 2 As shown, the precision measuring device based on roundness and cylindricity provided by the present invention has a measuring instrument body, and the measuring instrument body includes a base 1 and a control platform 13 mounted on the base. A control panel 12, an air-floating main shaft 6 and an air-floating column guide rail 10 are arranged above the control platform. A self-aligning and leveling table 7 is installed above the air-floating main shaft. A horizontal guide rail 11 is installed horizontally in front of the air-floating column guide rail. The part is provided with a sensor bracket 9, the sensor 8 is connected with the horizontal rail through the sensor bracket, the lower computer 3 is connected with the device through USB and Ethernet, and the information is fed back to the upper computer 2, and the information processed by the upper computer is passed through the computer. The display 4 realizes the real-time display of informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com