Surface creeping wave absorption coating structure

A technology of absorbing coatings and creeping waves, applied in electrical components, antennas, etc., can solve the problems of strong targeted application and complex structure, and achieve the effect of reducing thickness and width, reducing influence and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

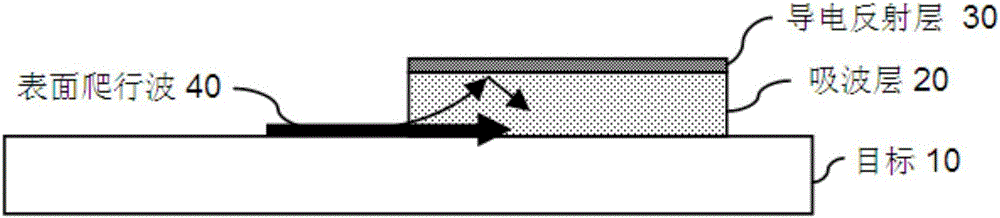

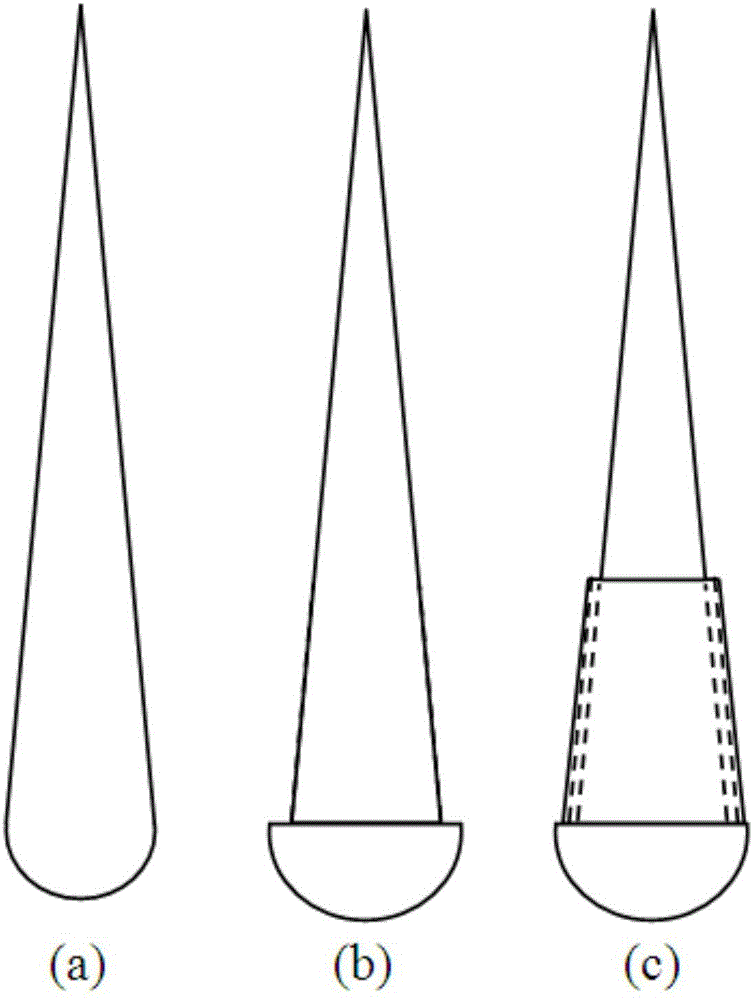

[0026] like figure 1 Shown is a surface creeping wave absorbing coating structure of the present invention, which is coated on the surface of the target 10, and the coating structure includes a wave-absorbing layer 20 and a conductive reflective layer bonded from the inside to the outside of the target 10 surface. Layer 30, the wave-absorbing layer 20 can absorb and convert the electromagnetic waves crawling on the surface of the target (i.e., the surface crawling waves 40) into heat energy, and the conductive reflective layer 30 has a reflection effect, which can suppress the external radiation of the crawling electromagnetic waves entering the wave-absorbing layer ; The material of the wave-abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com