Austenitic stainless steel and method for producing same

A technology of austenitic system and manufacturing method, which is applied in the field of stainless steel and its manufacturing, can solve the problem that stainless steel does not have hydrogen embrittlement resistance and high-strength machinability, and achieve excellent machinability, excellent hydrogen embrittlement resistance and high-strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0110] [experiment method]

[0111] Molten steels having chemical compositions of test numbers A1 to A20 and B1 to B9 shown in Table 1 were produced using a vacuum melting furnace.

[0112] [Table 1]

[0113]

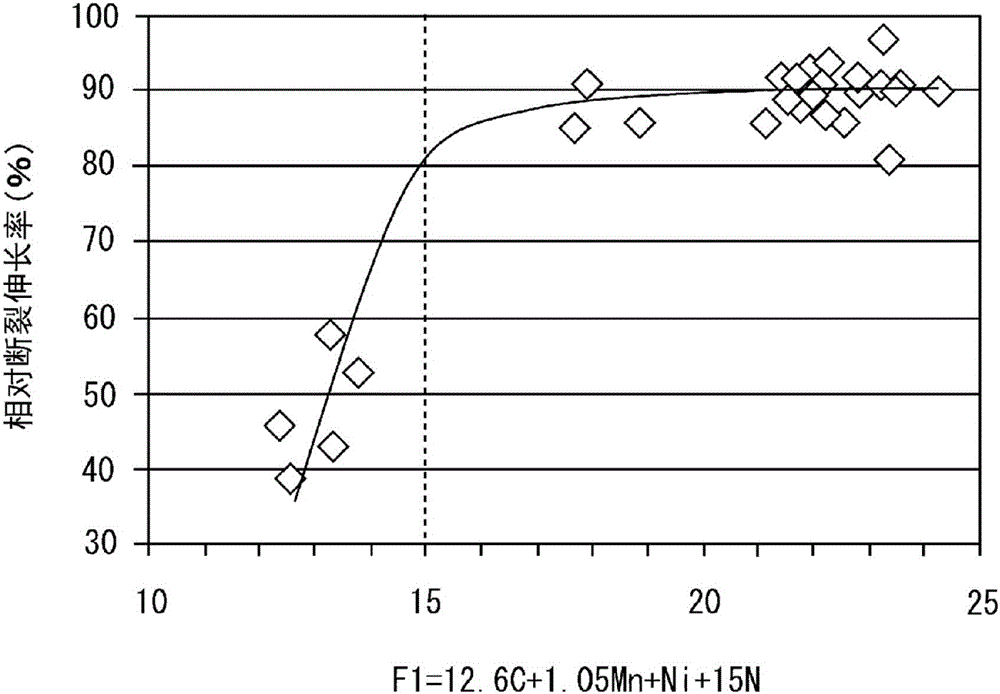

[0114] F1 in Table 1 is described as the F1 value defined above. Using the molten steel of each test number, 50 kg of ingots were produced. Hot forging was performed on the ingot to produce a block with a thickness of 70 mm.

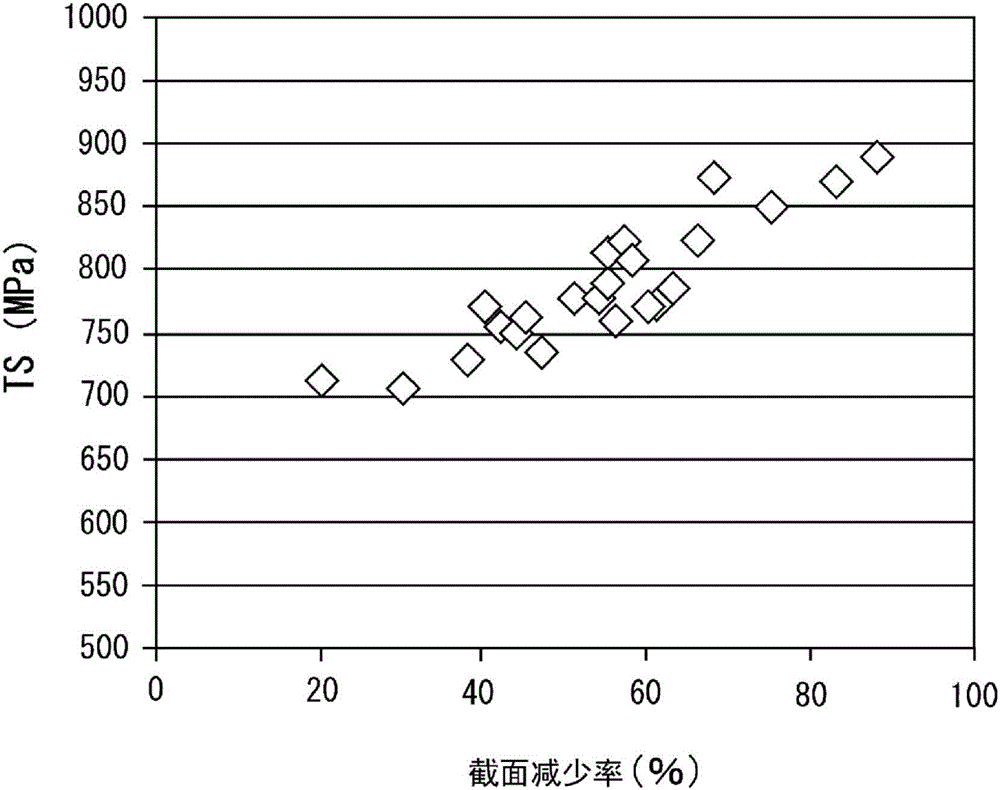

[0115] For the produced block, final hot working (hot rolling) is performed to produce an austenitic stainless steel sheet. Table 2 shows the heating temperature (° C.) and area reduction ratio RA (%) during the final hot working. Only test number B9 was subjected to solution heat treatment. The temperature of the solution heat treatment was 1060° C., and the heating time was 30 minutes.

[0116] [Table 2]

[0117]

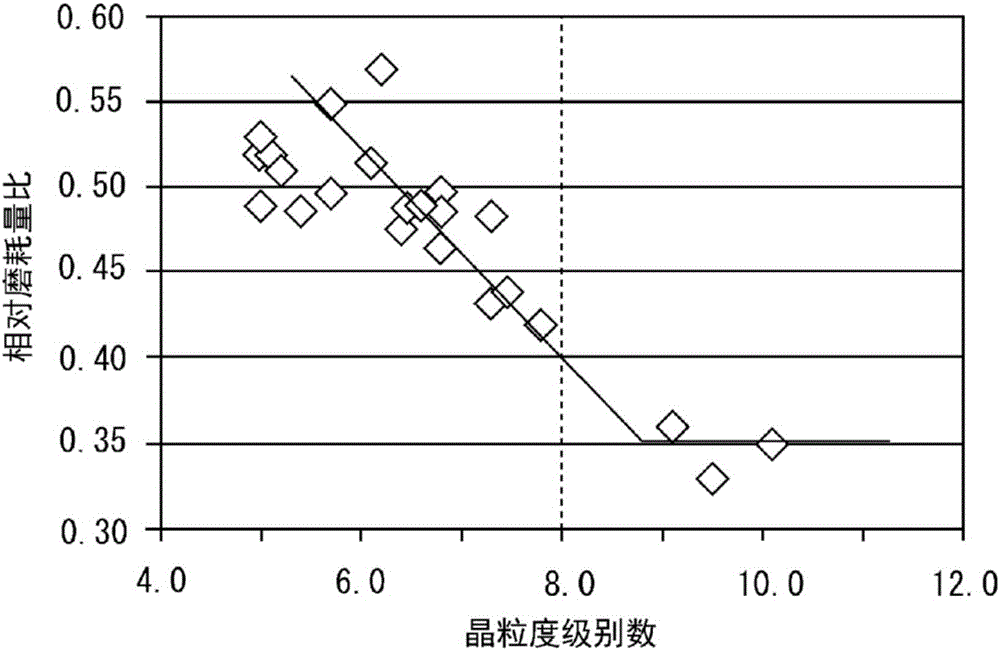

[0118] [Determination test of grain size]

[0119] The steel plate of each test number was cut|disconnected perpendicu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com