Automatic cow shed

A cow shed and shed body technology, applied in the field of dairy cattle breeding, can solve the problems of bacteria breeding, harmful bacteria affecting milk quality, etc., and achieve the effects of reasonable structure, accelerated air flow and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

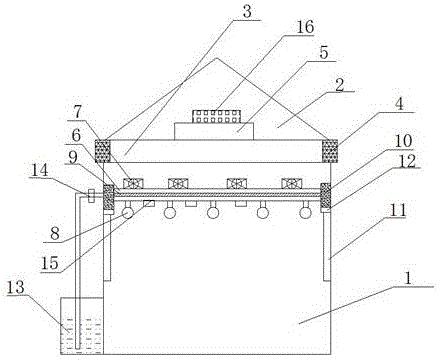

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 Shown, a kind of automatic cowshed, comprises shed body 1, top cover 2, ventilation chamber 3, aerosol nozzle 8, sliding assembly, ventilation fan 4 and exhaust fan 7, shed body 1 upper end is provided with top cover 2, shed body 1 and Ventilation chamber 3 is arranged between the top cover 2, ventilating fan 4 is installed at both ends of ventilation chamber 3, and support 6 is arranged in shed body 1, and support 6 is connected with the sliding assembly on both sides of shed body 1, and the upper end of support 6 is fixedly installed with Several exhaust fans 7, several aerosol nozzles 8 are installed on the lower end of the bracket 6, a liquid collection box 13 is provided on one side of the shed body 1, and the liquid collection box 13 is connected with the aerosol nozzle 8 through the liquid inlet pipe 9 in the bracket 6, A controller 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com