Temperature-controlled instant heating system for water purifying and drinking machine and control method of temperature-controlled instant heating system

A heating system and pure drinking machine technology, which is applied to fluid heaters, beverage preparation devices, lighting and heating equipment, etc., can solve problems such as waste of energy, high cost, complex system structure, etc. Burning, prolonging the service life, and the effect of simple flow path structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

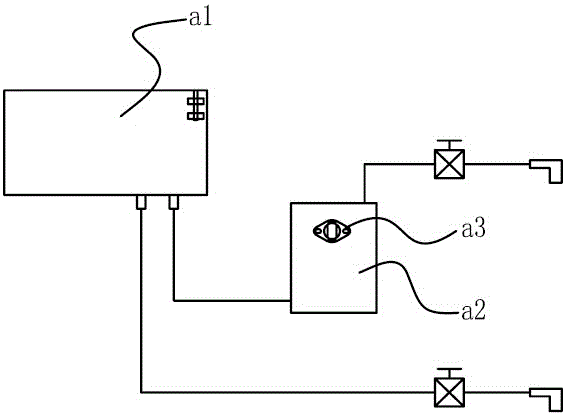

[0039] Such as Figure 4 As shown, a temperature-controlled instant heating system of a pure drinking machine includes a pure water tank 1 , and the pure water tank 1 is provided with a first water outlet 11 and a second water outlet 12 .

[0040] The water in the pure water tank 1 is normal temperature water or hot water with a lower temperature, and the water in the pure water tank 1 can be directly released for drinking, so the first water outlet 11 of the pure water tank 1 is directly connected to a common water outlet by a pipeline 21 is enough.

[0041] The second water outlet 12 of the pure water tank 1 is connected to the inlet of the flow regulating water pump 31 by pipelines, and the pipeline between the second water outlet 12 and the inlet of the flow regulating water pump 31 is provided with a first temperature sensor 32, and the flow regulating water pump 31 The outlet pipeline is connected to the water inlet end of the thermal heating device 33, and the water ou...

Embodiment 2

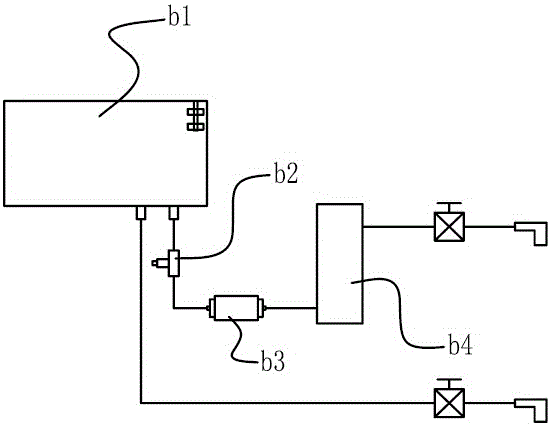

[0052] Such as Figure 6 As shown, this embodiment is improved on the basis of Embodiment 1.

[0053] First of all, this embodiment adds a water inlet 15 on the pure water tank 1, and the water inlet 15 of the pure water tank 1 is connected to the reverse osmosis filter type water purification system 4, so that the drinking water purifier of the present embodiment has a water purification function and enriches The function of the product makes the product more high-end.

[0054] The pure water tank 1 is provided with an upper limit float switch 16 and a lower limit float switch 17 .

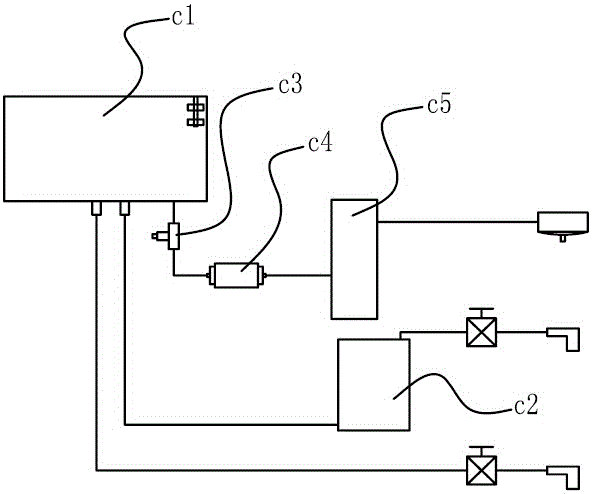

[0055] Such as Figure 7 As shown, the reverse osmosis filter type water purification system 4 , the upper limit float switch 16 and the lower limit float switch 17 are all circuit-connected to the main control board 91 .

[0056] When the lower limit float switch 17 was triggered, it was explained that the water yield in the pure water tank 1 was not enough. Now, the instant heating device 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com