Automatic Calibration Process For Coffee Grinder-Doser Apparatuses With Weighing Device And Electronic Grinder-Doser Apparatus

A technology of electronic grinding and calibration method, which is applied in the direction of weighing equipment testing/calibration, coffee mill, beverage preparation device, etc. It can solve the problems of unreliable weighing value, uncomfortable results, fragile and other problems, and achieve easy construction and Electronic execution, good technical content, use of generic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

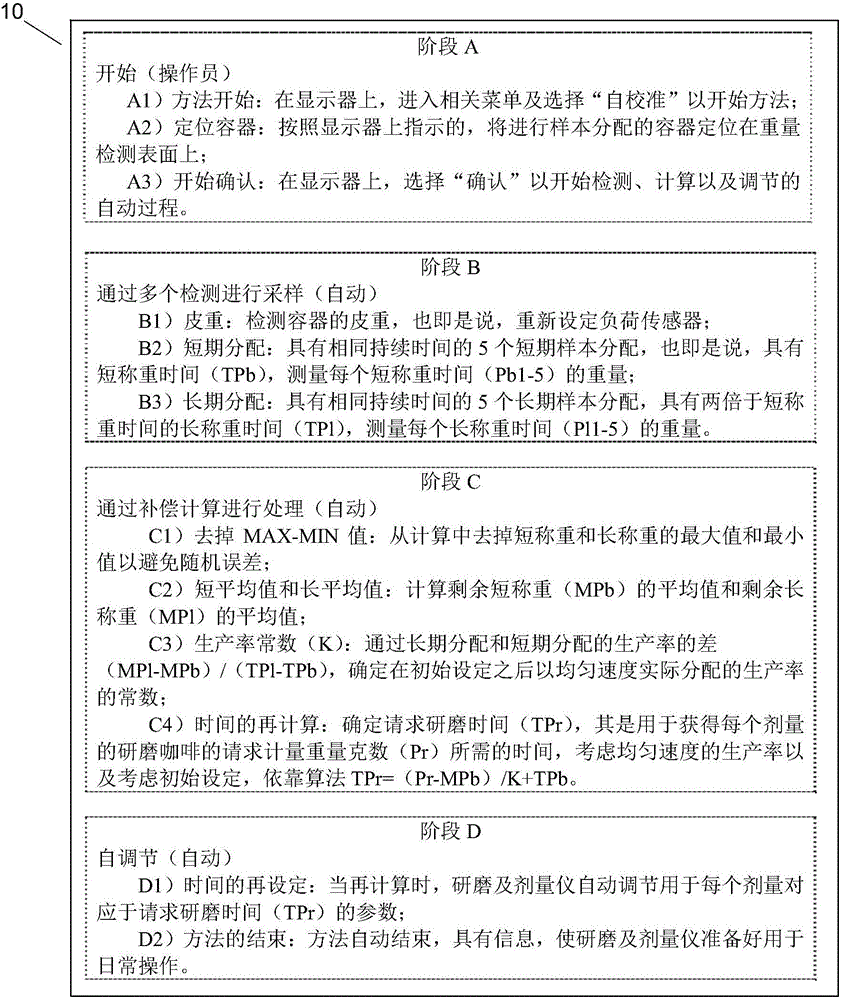

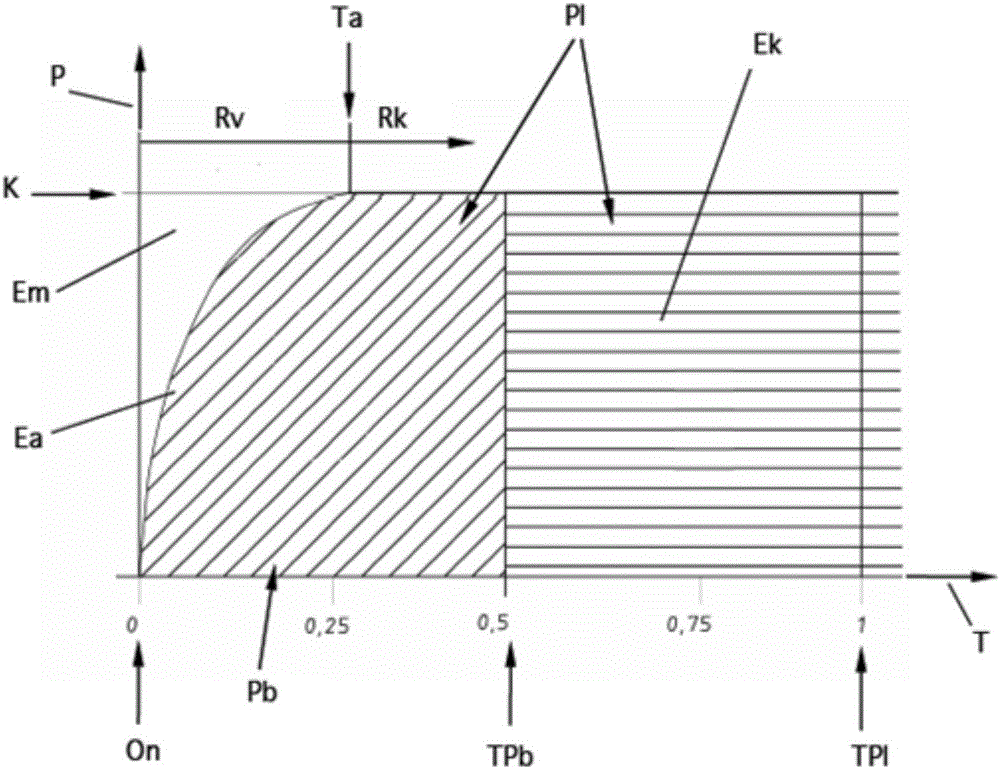

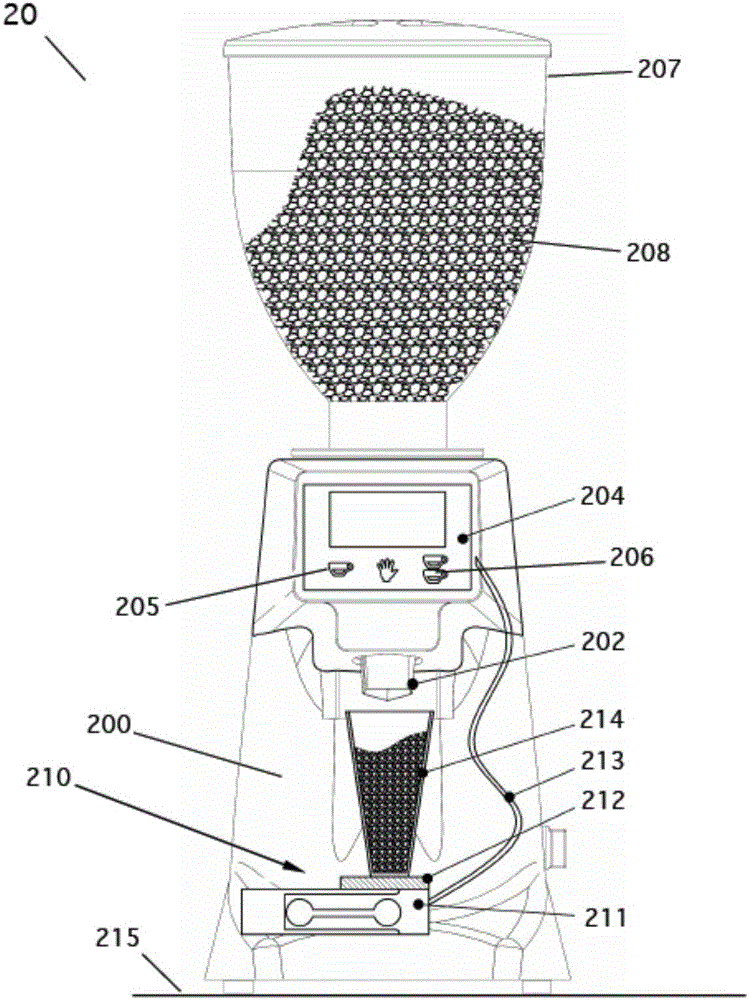

[0042] Also refer to the accompanying drawings ( Figure 1-Figure 4 ), the present invention relates to an automatic calibration method 10 ( Figure 1-Figure 2 ), also relates to an electronic grinding and dosimeter device 20 for coffee beans, which is advantageously according to the method ( Figure 3-Figure 4 ) is capable of self-calibration; in particular, the method is suitable for grinding and dosimeter devices, which are integrated in front of an electromechanical system for dosing control of ground coffee, called dispenser 201, while the shutter can directly Managed by the logic control unit 203, in particular provided with an electronic weighing device 210 directly connected to the logic unit 203, the electronic weighing device 210 is used to periodically adjust the set grinding time, depending on the quality of the coffee actually ground and dispensed, the grinding Times vary due to several factors. The method 10 and the device 20 enable a professional operator to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com