Efficient low wind resistance filter element and preparation method thereof

A filter element and wind resistance technology, applied in the field of high-efficiency and low wind resistance filter element and its preparation, can solve the problems of low filtration precision, single filter device structure, large wind resistance, etc., and achieve the effect of improving the air in the car, widening industrial value, and good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

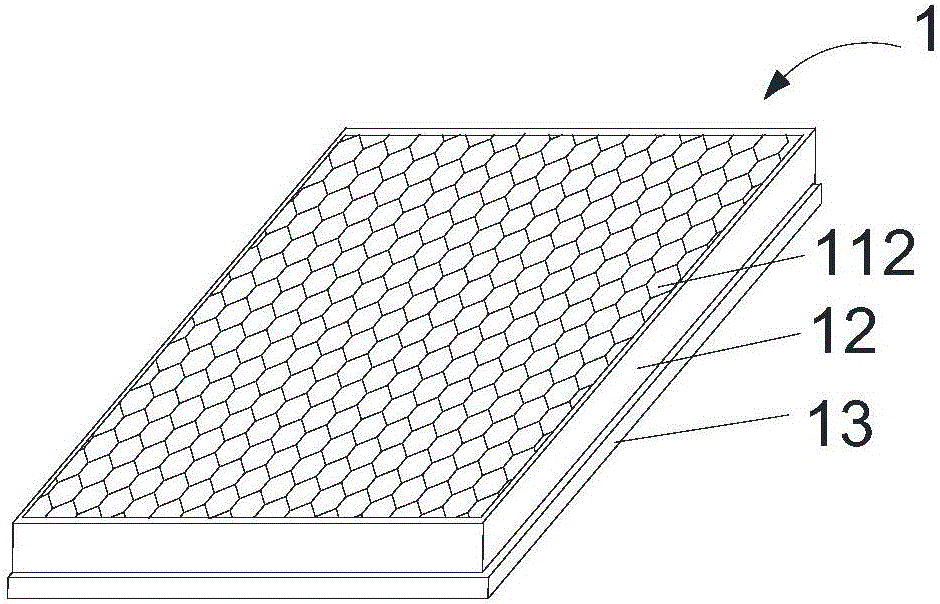

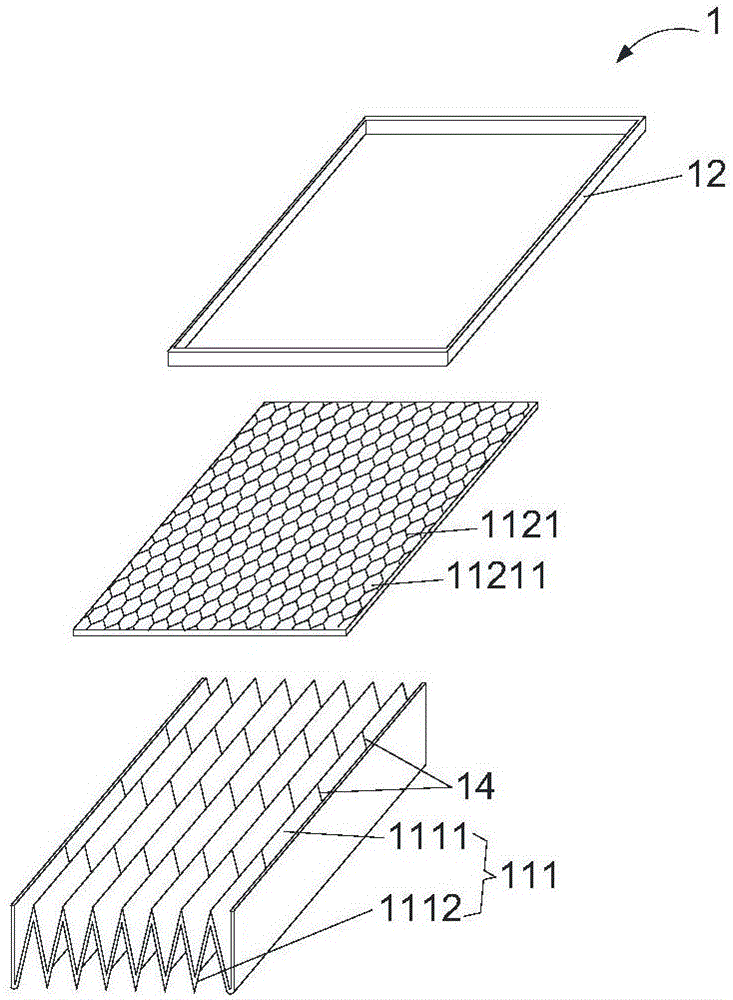

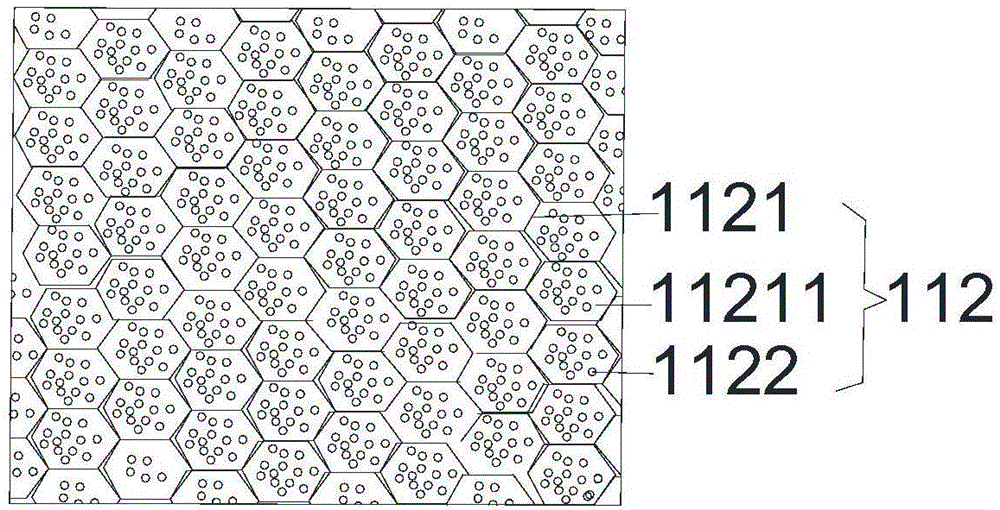

[0039] see Figure 1 to Figure 4 , the present invention provides a high-efficiency and low wind resistance filter element 1, comprising a filter element body 11; the filter element body 11 includes a filter paper layer 111 and a honeycomb filter layer 112; the filter paper layer 111 includes a bacteriostatic layer 1111, and the The melt-blown electrostatic electret layer 1112 connected to the bacterial layer 1111; the honeycomb filter layer 112 is placed on the side of the antibacterial layer 1111 away from the melt-blown electrostatic electret layer 1112; the honeycomb filter layer 112 includes a honeycomb support A rack 1121 and a filter material 1122; the honeycomb support frame includes a storage unit 11211 arranged in a honeycomb shape; the filter material 1122 is filled in the storage unit 11211.

[0040] Above, it can be seen from this structure that only one layer of antibacterial layer 1111 is used to replace the natural plant bactericidal antibacterial layer 1111 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com