Preparation method and application of iron-copper composite catalyst

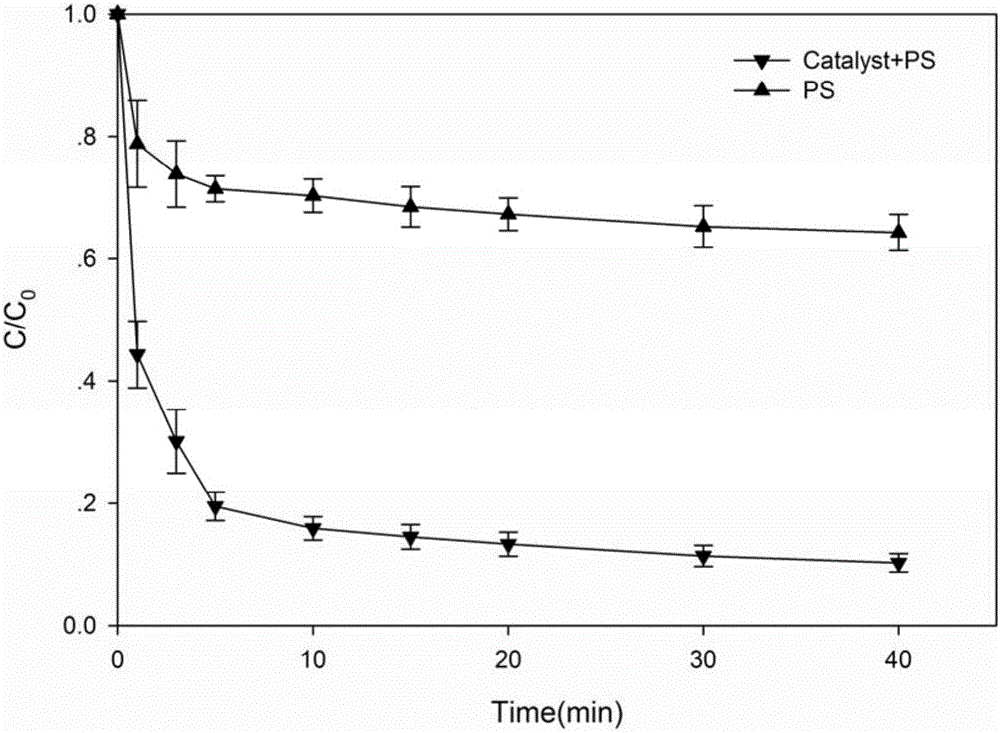

A composite catalyst, iron-copper technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of weak catalytic performance, increase processing costs, and cannot be widely used and other problems, to achieve the effect of less dosage, high efficiency and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 0.01 to 0.04 mol of ferrous sulfate in a mixed solution of ethanol and deionized water (20 to 80 mL of ethanol, 120 to 180 mL of deionized water), then add 0.01 to 0.5 mol of urea, and stir until dissolved;

[0035] (2) The material obtained in step (1) was magnetically stirred and refluxed in an oil bath at 70-90°C for 0.5-6 hours, and after natural cooling, it was centrifuged and washed several times to obtain a precipitate, which was dried at 70°C for 8-16 hours;

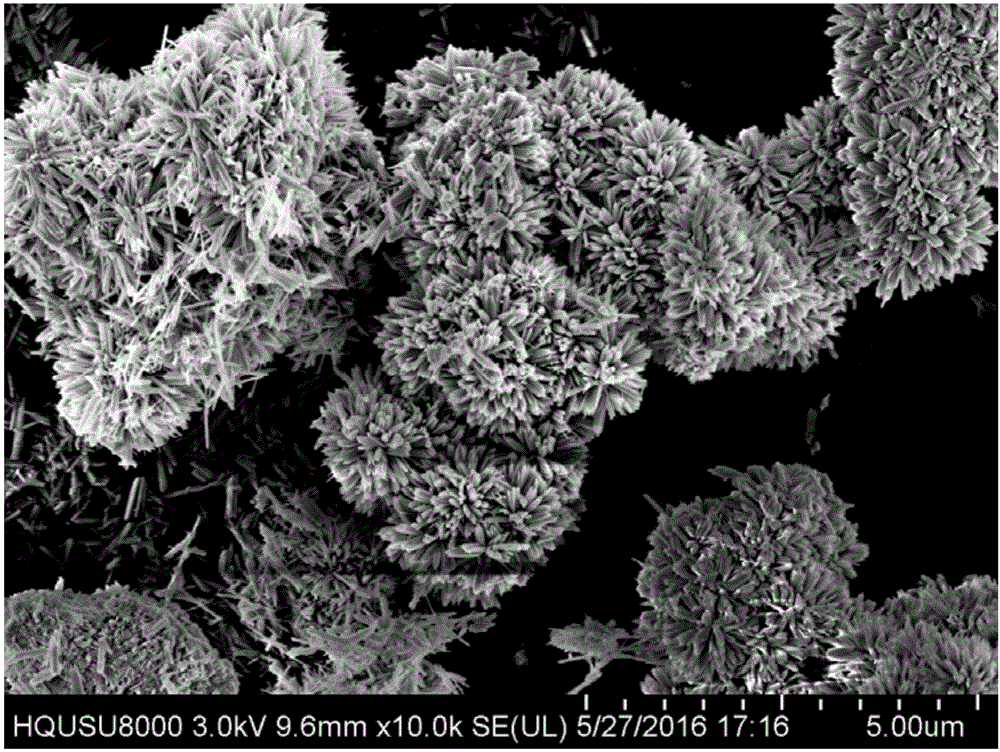

[0036] (3) calcining the material obtained in step (2) at 400-600°C for 3-5 hours, and cooling naturally figure 1 the first component shown;

[0037] (4) 1~5mol copper nitrate is completely dissolved in the mixed solution of ethanol and ethylene glycol, and the volume ratio of ethanol and ethylene glycol is 1:2~3;

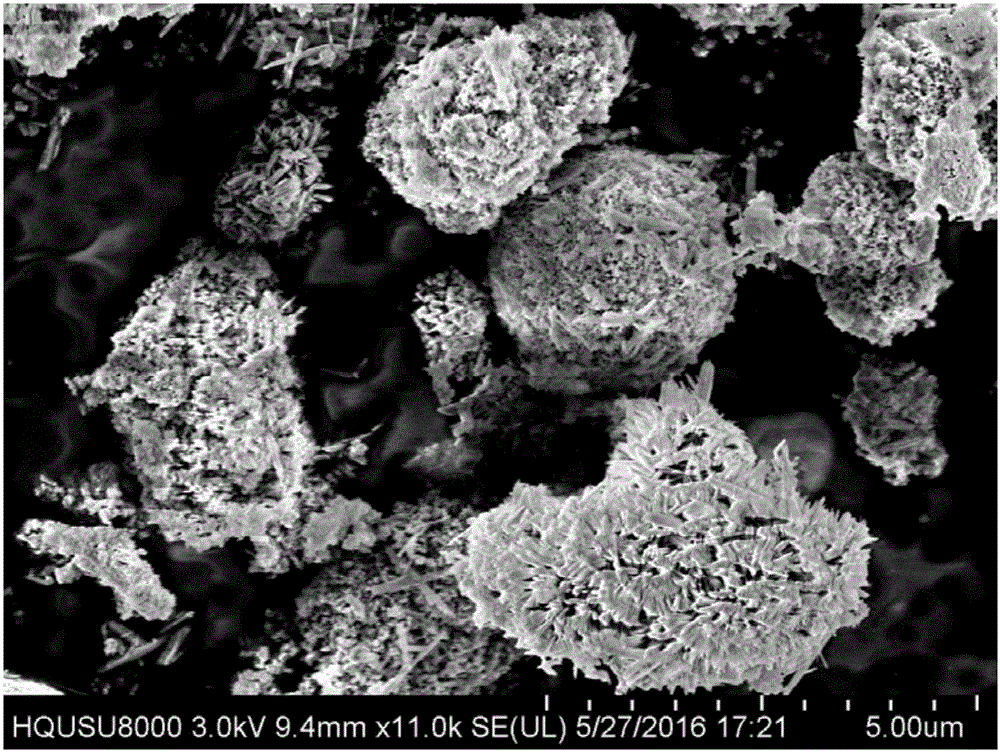

[0038] (5) Add 25g of the first component to the material in step (4), ultrasonically disperse the first component for 10-30 minutes, and then transfer it to a high-pressure react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com