A-SnWO4/In2S3 composite photocatalyst

A composite light and catalyst technology, applied in the field of photocatalysis, can solve the problems of limiting practical application and reducing photocatalytic activity, and achieve the effects of wide application prospects and industrialization prospects, rich active sites, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

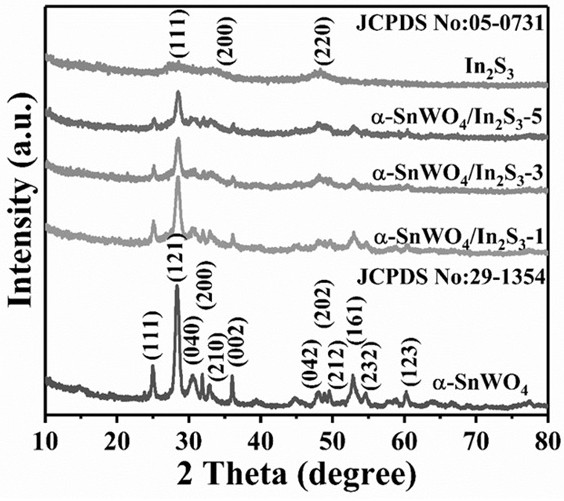

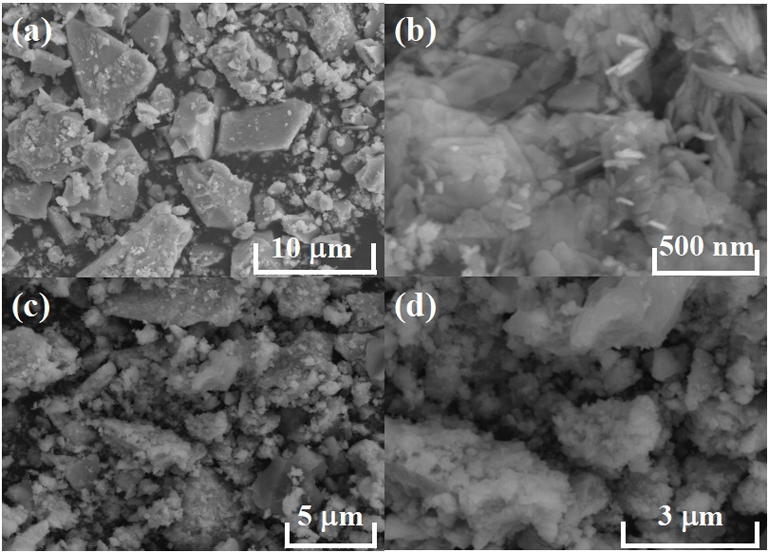

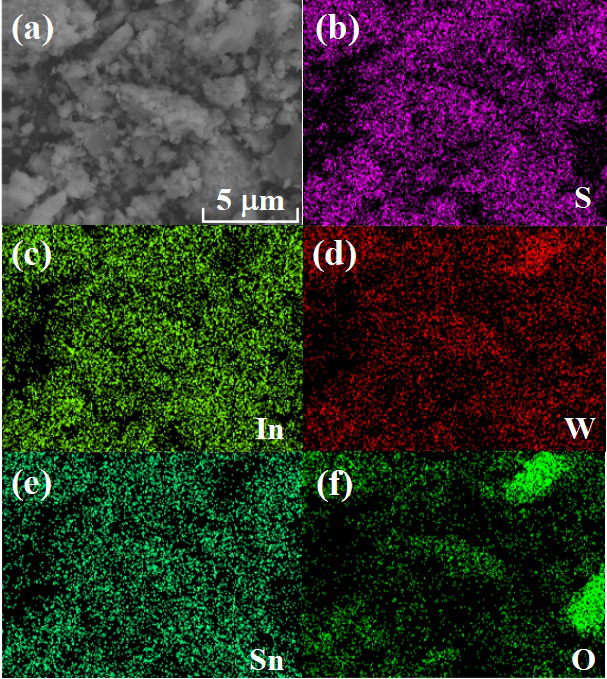

[0034] a-SnWO 4 / In 2 S 3 The preparation method of composite photocatalyst comprises the steps:

[0035] (1) Preparation of a-SnWO by hydrothermal method 4 Nanosheets;

[0036] 1.3297 g SnCl 2 ×2H 2 O is completely dissolved in 0.1 mol / L HCL, and 1.7998 g Na 2 WO 4 ×2H 2 O was completely dissolved in 20 ml deionized water; the Na 2 WO 4 ×2H 2 O solution was added dropwise to SnCl 2 ×2H 2 O solution, and vigorously stirred to form a mixed solution;

[0037] Use 0.1 mol / L NaOH solution to adjust the pH value of the above mixed solution to 7 and stir vigorously for one hour; transfer the solution in step (5) to a 100 ml reactor for reaction, the reaction temperature is 200 °C, and the reaction time is 24 hours ;

[0038] After the reaction, the product was collected in a vacuum oven and dried at 60 °C for 12 hours to obtain a-SnWO 4 Nanosheets.

[0039] (2) Then put a-SnWO 4 load at In 2 S 3 surface;

[0040] Put 1.35 mmol of anhydrous citric acid in beaker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinetic constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com