Dust removal system, with alternating magnetic dust removal pipe, for workshop

A technology of alternating magnetic field and dust removal system, applied in the direction of external electrostatic separator, power supply technology, electrostatic separation, etc., can solve the problems of high energy consumption, lack of dust detection device, inability to clean lint and dust, etc., and achieve a high degree of intelligence , High dust removal efficiency and timely dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

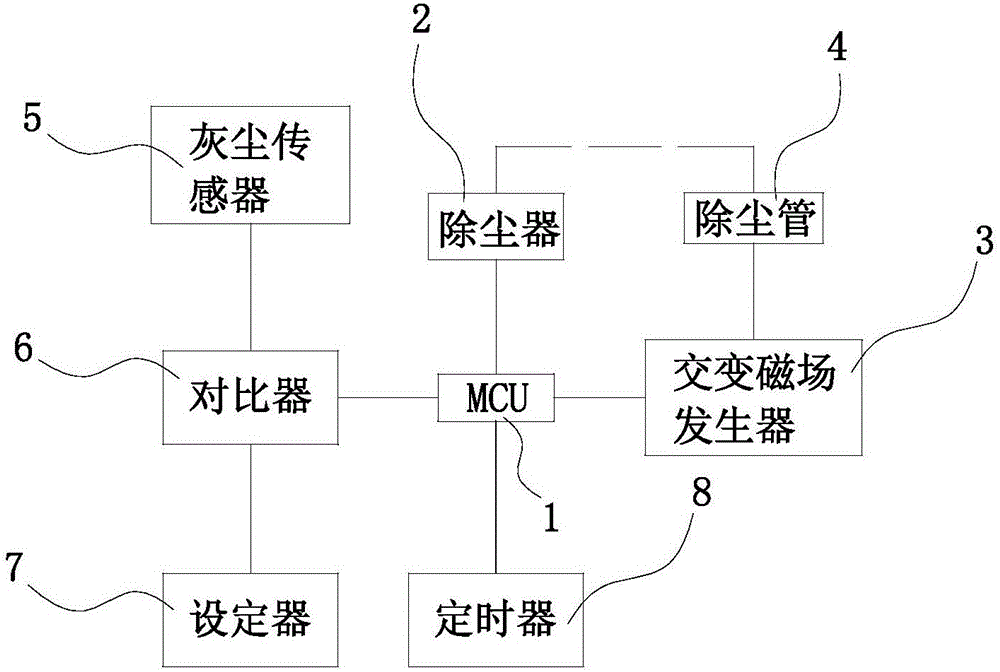

[0012] Such as figure 1 As shown, the alternating static voltage type workshop dust removal system of this embodiment includes a dust collector 2 and a dust sensor 5 installed in the workshop, and the dust sensor 5 is installed at the end of the air duct of the dust collector 2. Control the dust collector 2; the dust removal pipe 4 of the dust collector 2 is connected with the alternating magnetic field generator 3, and the alternating magnetic field generator 3 is controlled by the MCU1; the dust sensor 5 is connected with the MCU1 through the comparator 6, and the input end of the comparator 6 is also connected The setting device 7 and the MCU1 are also equipped with a timer 8 .

[0013] The present invention detects the amount of dust in the workshop through the dust sensor 5, and when the detected amount of dust is greater than the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com