Tube type ejector with function of quickly sucking and spraying anticorrosive paint through servo electrical direct drive

An anti-corrosion coating, servo-electric technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of short spraying distance, complex structure, complicated operation, etc., and achieve the effect of rapid suction and spraying, fast response speed and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

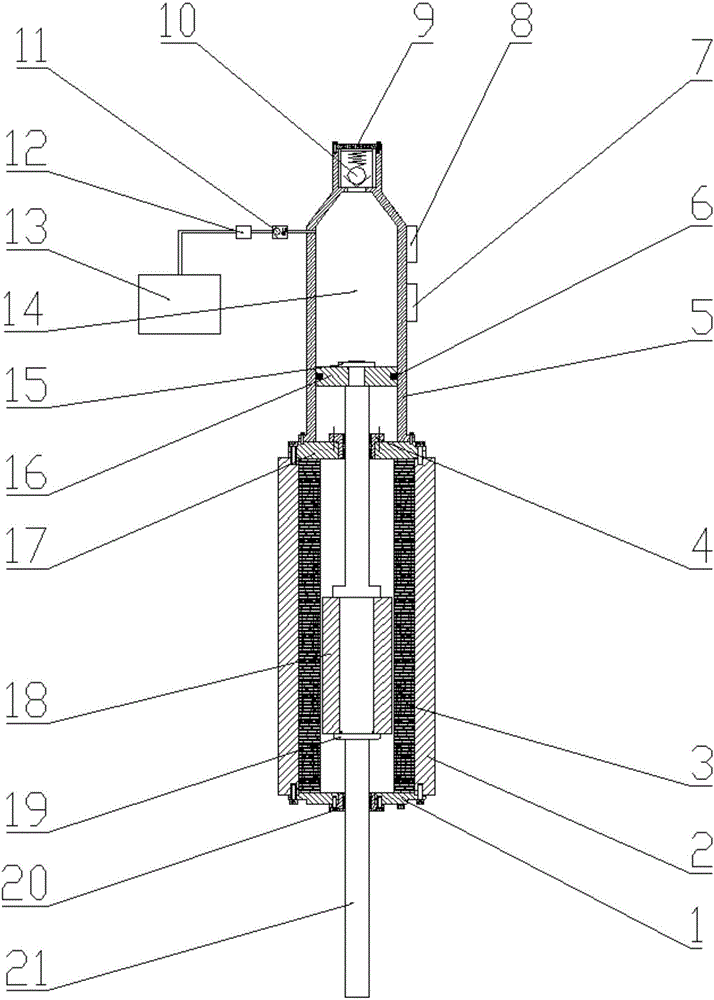

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] refer to figure 1 , a tube type injector for quickly absorbing and spraying anti-corrosion coatings with servo electric direct drive, comprising a motor mover 18, the motor mover 18 is installed in the middle of the long axis 21 of the linear motor, and the first nut 19 fixes the motor mover 18 on the On the long shaft 21 of the linear motor, the upper end of the long shaft 21 of the linear motor is installed on the first flange 17 through the first bearing 4, the first flange 17 is installed on the upper end of the motor cylinder 2, and the lower end of the long shaft 21 of the linear motor passes through The second bearing 20 is installed on the second flange 1, and the second flange 1 is installed on the lower end of the motor cylinder 2. The long axis 21 of the linear motor can reciprocate up and down. The first flange 17 and the second method The blue pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com