Open-type mold drying device

An open, mold-baking technology, which is applied in the field of casting rolls, can solve the problems of inconvenient picking and placing of products, slow and insufficient heating, and achieve the effects of preventing over-baking or insufficient baking, increasing the heating rate, and reducing product damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

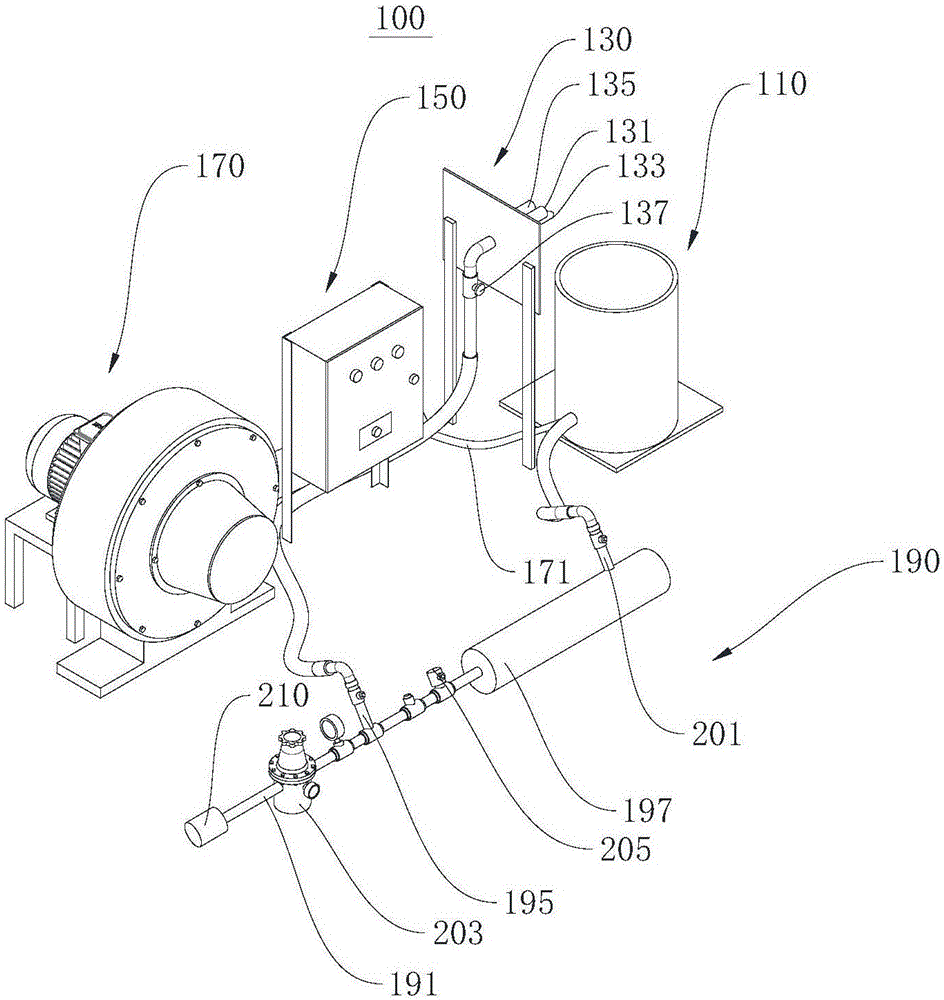

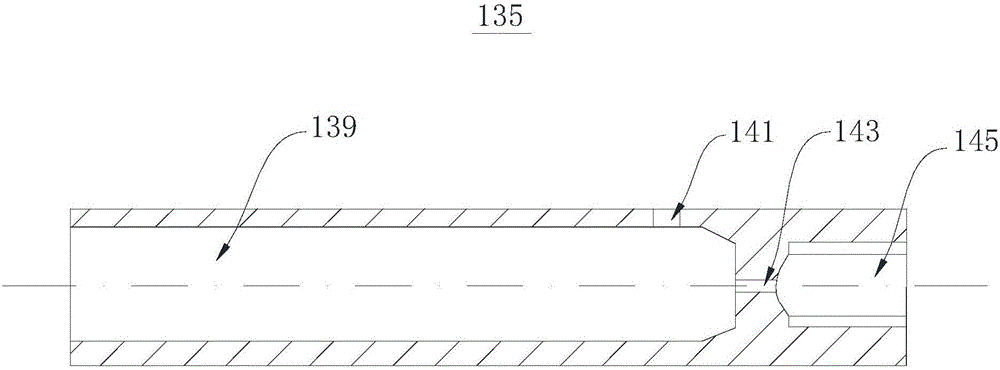

[0034] Please refer to figure 1 This embodiment provides an open mold drying device 100, which includes a mold drying oven 110, an ignition device 130, a switch box 150, a fan 170, a gas delivery pipeline 190, and a gas supply device 210 for providing gas. The ignition device 130 is adjacent to the mold oven 110 , the fan 170 and the ignition device 130 are electrically connected to the switch box 150 respectively, and the gas supply device 210 and the fan 170 are respectively connected to the mold oven 110 through the gas delivery pipeline 190 .

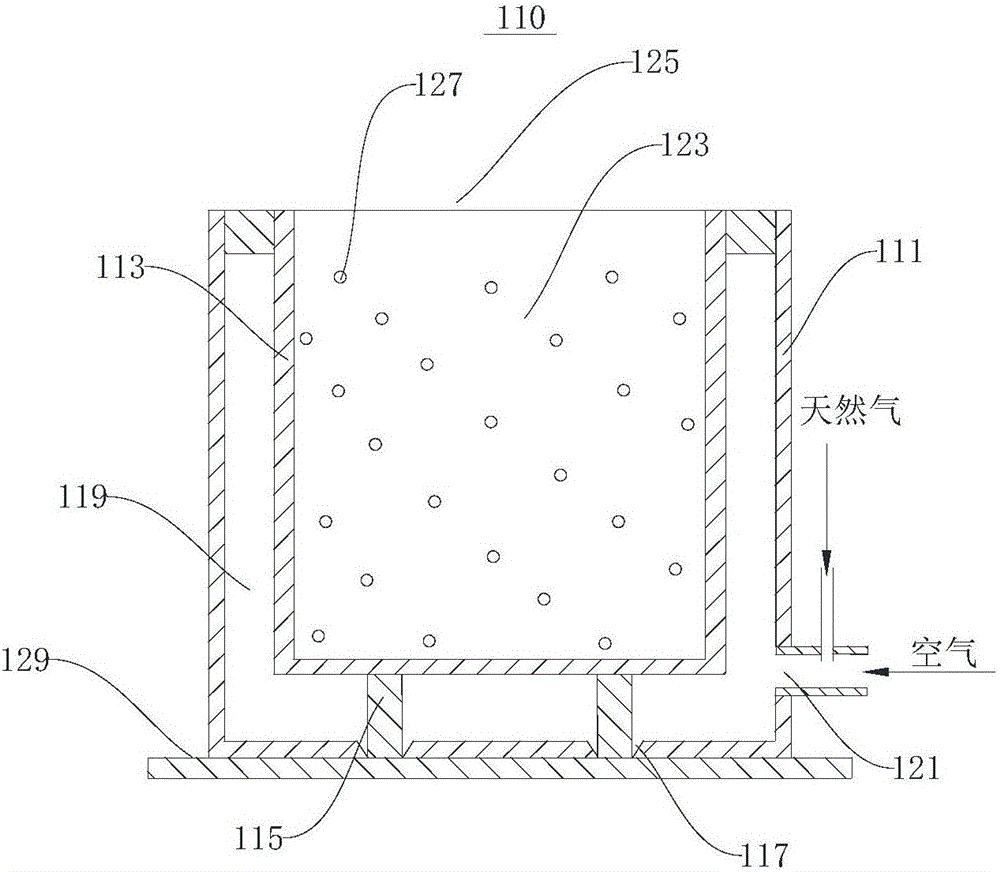

[0035] For a more clear description of the structure of the mold oven 110, please refer to figure 2 , The mold oven 110 includes a shell 111 , an inner tank 113 , and an inner tank bracket 115 . The inner tank 113 is nested in the outer shell 111, and the outer shell is provided with a bracket hole 117 for fixing the inner tank bracket 115, and supports the inner tank 113 through the inner tank bracket 115, so as to form between t...

no. 2 example

[0053] This embodiment provides an open mold drying device 300 , which is mainly different from the open mold drying device 100 provided in the first embodiment in that: the setting of the mold drying oven is different and the arrangement of the gas delivery pipes is different.

[0054] For details, please refer to Figure 4 , the open mold drying device 300 includes a mold oven 110 and a gas delivery pipeline 190a.

[0055] The mold oven 110 comprises a first mold oven 311, a second mold oven 313, a third mold oven 315 and a fourth mold oven 317, wherein the first mold oven 311, the second mold oven 313, the third mold oven Both the mold oven 315 and the fourth mold oven 317 have the same structure as the mold oven 110 in the first embodiment. The first mold oven 311 , the second mold oven 313 , the third mold oven 315 , and the fourth mold oven 317 are independently fired, and are connected to the fan 170 and the gas supply device 210 through the gas delivery pipeline 190 ....

no. 3 example

[0061] This embodiment provides an open mold drying device 500 , which is mainly different from the open mold drying device 300 provided in the second embodiment in that: the setting of the mold drying oven is different and the arrangement of the gas delivery pipes is different.

[0062] see Figure 6 , the open mold drying device 500 includes a mold oven 110 and a gas delivery pipeline 190b.

[0063] The first mold oven 311, the second mold oven 313, the third mold oven 315, and the fourth mold oven 317 all also include a temperature measuring instrument 511 located on the heat insulation base 129, and the temperature measuring instrument 511 can measure the temperature of the oven. The temperature inside the mold cavity 123. The first mold oven 311, the second mold oven 313, the third mold oven 315, and the fourth mold oven 317 have the same structure, and the specific structure takes the first mold oven 311 as an example, please refer to Figure 7 .

[0064] see Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com