Production method for reducing length of water gap replacing blank in continuous casting process

A production method and technology for changing nozzles, which are applied in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problem of poor cleanliness, non-compliance with cost reduction, efficiency enhancement, quality improvement, and unfavorable high-quality clean steel platforms. production and other problems, to achieve the effect of increasing the proportion of cast billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

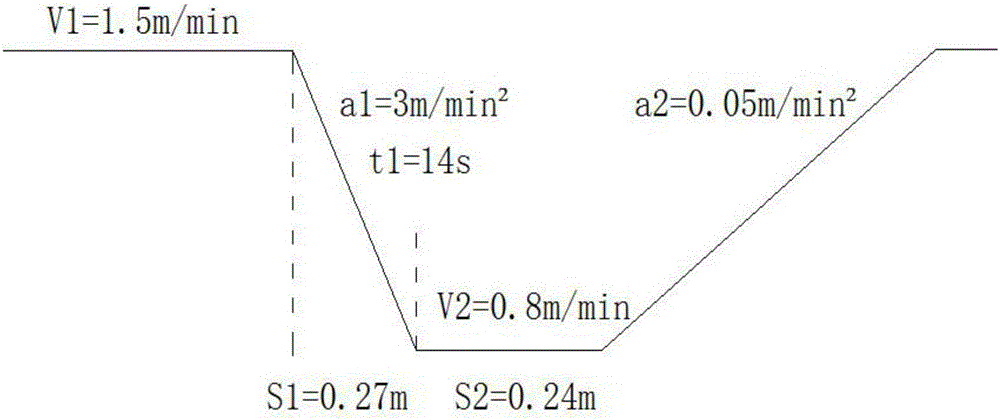

[0049] Such as figure 1 As shown, set the target pulling speed V1=1.5m / min of the continuous casting process,

[0050] Reduce the target drawing speed to the drawing speed V2=0.8m / min when changing the billet according to the uniform deceleration mode, and the acceleration of the uniform deceleration is a1=3m / min 2, the time taken by the entire deceleration operation is t1=14s, the displacement of the slab S1=0.27m,

[0051] Adjust the opening of the stopper rod, and the liquid level rises by 15mm at a rate of 0.15m / min, so that the crystallizer liquid level rises to the target liquid level of the water change port.

[0052] Maintain the drawing speed when changing the water billet for 20 seconds, so that the cast billet meets the length requirement,

[0053] After reaching the cut length, select the minimum pressure mode to automatically close the stopper rod,

[0054] Keep the stopper closed for 4.5 seconds, and automatically complete the replacement of the nozzle based o...

Embodiment 2

[0060] The target pulling speed of setting described continuous casting process is 1.5m / min,

[0061] Reduce the target pulling speed to the pulling speed when changing the water billet according to the uniform deceleration mode, and the acceleration of the uniform deceleration is 2m / min 2 ,

[0062] Adjust the opening of the stopper rod, and the liquid level rises by 10mm at a rate of 0.1m / min, so that the crystallizer liquid level rises to the target liquid level of the water change port.

[0063] Maintain the drawing speed when changing the water billet for 10 seconds, so that the cast billet meets the requirement of fixed length,

[0064] After reaching the cut length, select the minimum pressure mode to automatically close the stopper rod,

[0065] Keep the stopper closed for 2.5 seconds, and automatically complete the replacement of the nozzle based on the program.

[0066] Open the stopper,

[0067] Increase the pulling speed when changing the nozzle billet accordin...

Embodiment 3

[0071] The target pulling speed of setting described continuous casting process is 1.5m / min,

[0072] Reduce the target pulling speed to the pulling speed when changing the water billet according to the uniform deceleration mode, and the acceleration of the uniform deceleration is 5m / min 2 ,

[0073] Adjust the opening of the stopper rod, and the liquid level rises by 20mm at a rate of 0.2m / min, so that the crystallizer liquid level rises to the target liquid level of the water change port,

[0074] Maintain the pulling speed when changing the water billet for 30 seconds, so that the cast billet meets the requirement of fixed length,

[0075] After reaching the cut length, select the minimum pressure mode to automatically close the stopper rod,

[0076] Keep the stopper closed for 3.5 seconds, and automatically complete the replacement of the nozzle based on the program.

[0077] Open the stopper,

[0078] Increase the pulling speed when changing the nozzle billet accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com