Electro-discharge milling method for micro-three-dimensional structure

A three-dimensional structure and milling processing technology, which is applied in the field of aerospace special processing, can solve problems such as low product efficiency, electrode loss, and product processing accuracy that cannot meet the design requirements, and achieve the effect of improving the processing erosion rate and reducing stress micro-deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

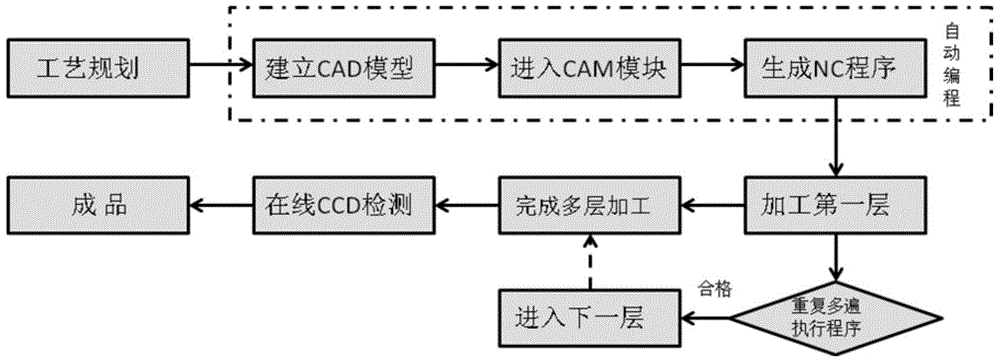

[0030] like figure 1 As shown, the micro three-dimensional structure electric discharge milling processing method of the present invention comprises the following steps:

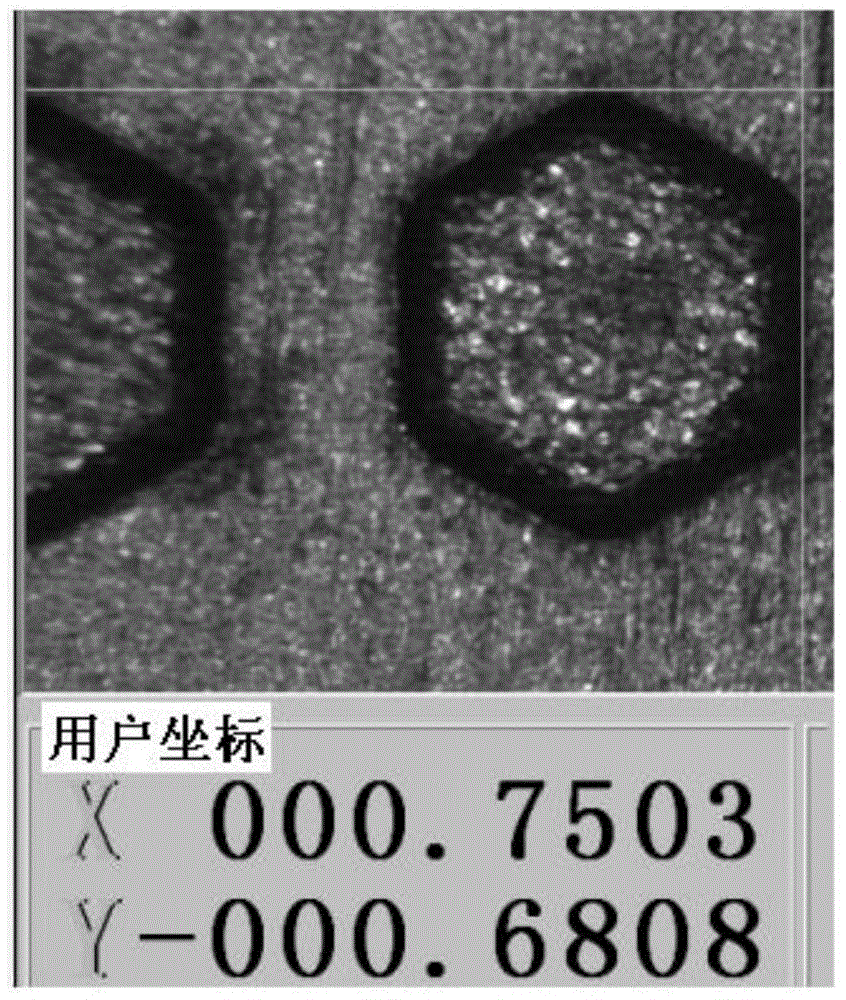

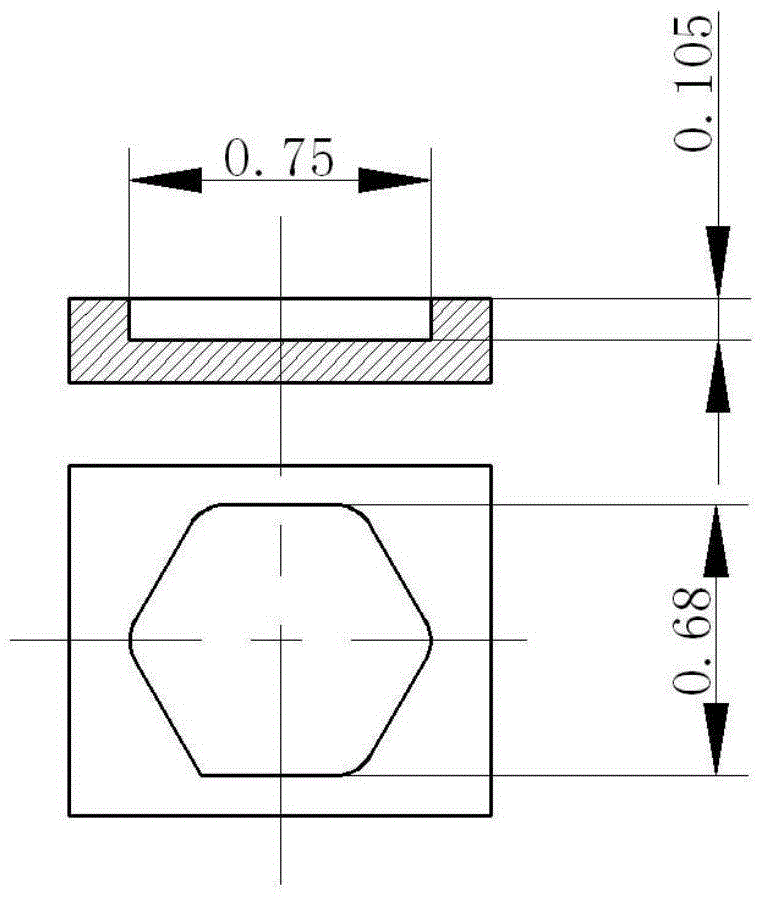

[0031] The invention is aimed at the three-dimensional structure of fine narrow grooves made of difficult-to-machine materials used in some key structures of aerospace generators, and its core component materials are mostly high-temperature alloys or titanium alloys. It is a hexagonal narrow groove micro three-dimensional structure part, such as figure 2 shown.

[0032] Step 1: Process planning:

[0033] According to the micro three-dimensional structure layered milling strategy, the movement trajectory of the electrode should take N layers as a cycle to select the optimal milling trajectory for processing, and the tool electrode removes material layer by layer from top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com