Weldability test dynamometry tool with solder position convenient to adjust

A technology of solderability and solder, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of slow automatic reset, sensitivity to be improved, inconvenient adjustment, etc., to achieve automatic fast reset, improve reset sensitivity, fast height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

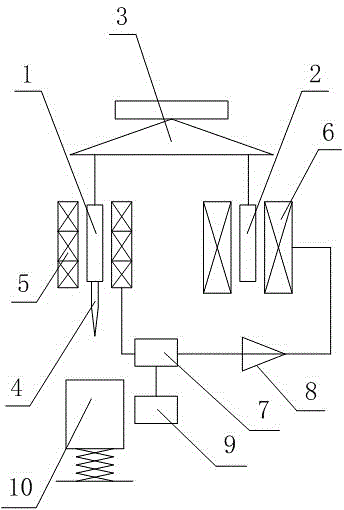

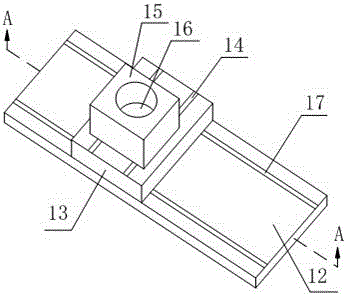

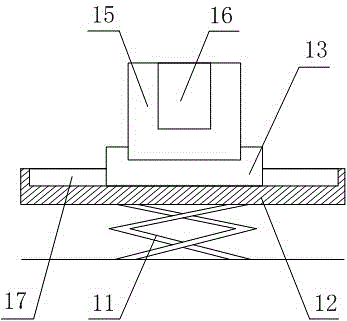

[0024] Such as Figure 1 to Figure 3 The shown one kind of weldability test force measuring tool that is convenient to adjust the position of the solder includes a balance mechanism 3, and the two ends of the balance mechanism 3 hang the first iron core 1, the second iron core 2, the first iron core 1 The lower end is connected to the sample fixture 4, the displacement sensor 5 is arranged on the side of the first iron core 1, and the electromagnetic coil 6 is arranged on the side of the second iron core 2; a solder holding part 10 is arranged directly below the sample fixture 4; it also includes a controller 7, an amplifying Circuit 8; the displacement sensor 5 detects the displacement of the first iron core 1 and transmits it to the controller 7; the controller 7 transmits the received signal of the displacement sensor 5 to the recording device 9 through A / D conversion; The received displacement sensor 5 signal is linearly converted into a current output, and transmitted to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com