Synchronous rocker sensor, controller and synchronous processing system and method

A sensor and rocker technology, applied in the field of new sensors, can solve the problems of short service life, increased gap between rocker sensor components, and loose structure, so as to improve integration and structure tightness, improve reset sensitivity, and improve The effect of self-reset capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

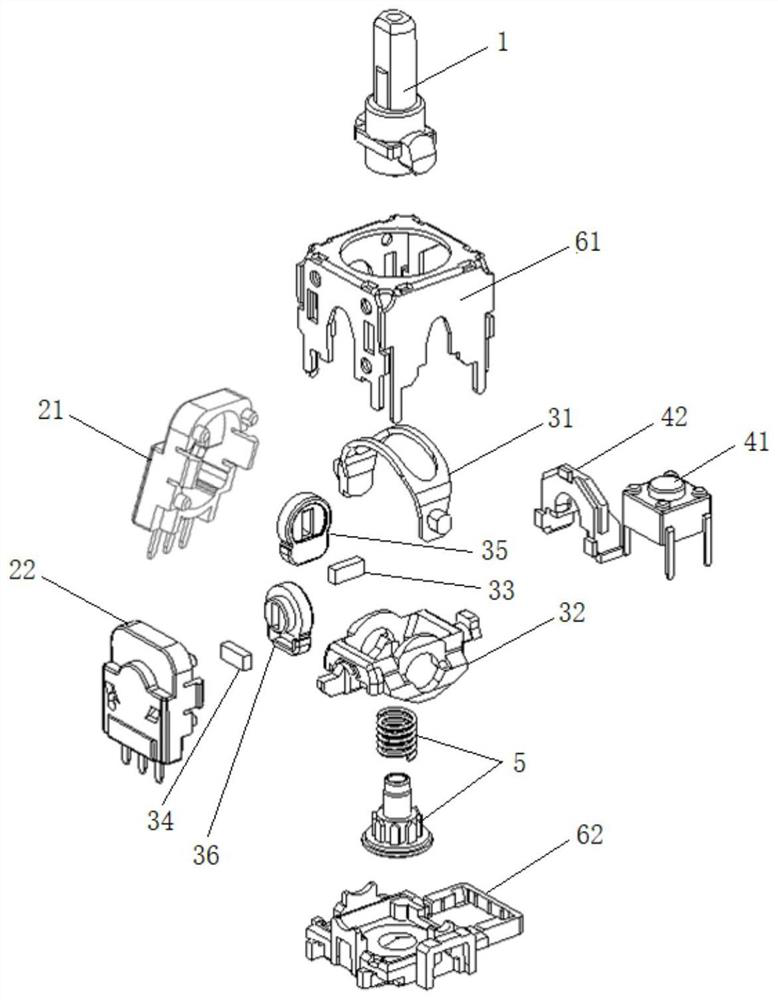

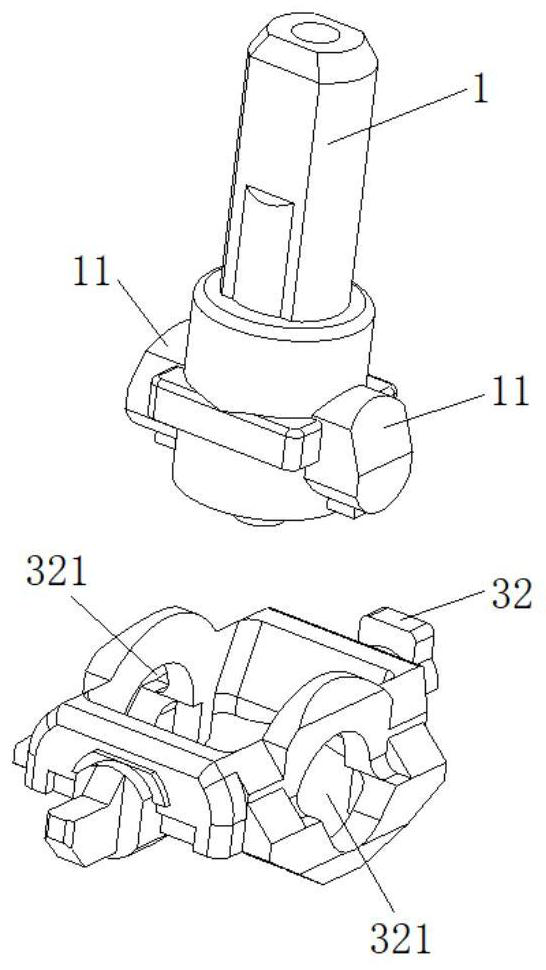

[0064] This embodiment provides a synchronous rocker sensor, such as figure 1 As shown, including rocker 1, rocker arm assembly and swing detection assembly;

[0065] The rocker assembly is sleeved on the rocker 1, and the rocker 1 pushes the rocker assembly to swing in a first direction and a second direction perpendicular to each other;

[0066] The swing detection component is used to respectively measure the swing amounts in the first direction and the second direction through the magnetic induction element and convert them into a first electric signal and a second electric signal respectively and output them. By replacing the existing variable resistance component with the magnetic induction element, the magnetic induction element realizes non-contact detection, thereby improving the service life.

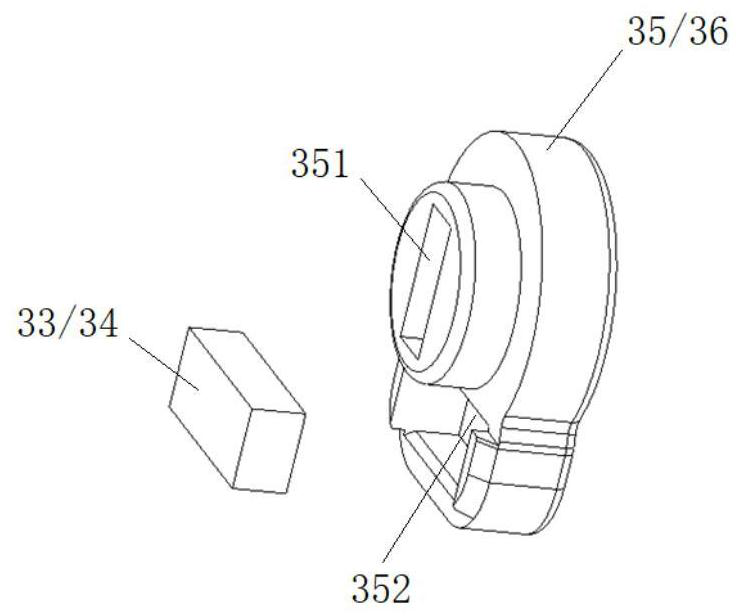

[0067] Preferably, the rocker arm assembly includes an upper rocker arm 31, a lower rocker arm 32, a first magnetic block 33, a second magnetic block 34, a first magnetic blo...

Embodiment 2

[0085] This embodiment provides a synchronous rocker sensor, such as Figure 8 with Figure 9 As shown, the difference from Embodiment 1 is that the reset assembly 5 includes a polyurethane elastic block 53 and a fixed base 54; one end of the rocker 1 is tightly connected to the upper surface of the polyurethane elastic block 53, and the polyurethane elastic block 53 is installed on the bottom surface of the polyurethane elastic block 53. On the fixed base 54 , the fixed base 54 is connected with the inner surface of the lower shell 61 ; the rocker 1 under the cancellation of the thrust automatically returns to the upright state under the self-restoring force of the polyurethane elastic block 53 .

[0086] The aforementioned synchronous rocker sensor uses polyurethane elastic blocks to improve the self-resetting capability of the reset component and improve the reset sensitivity of the rocker sensor. Through the tight connection between one end of the rocker, the polyurethane...

Embodiment 3

[0092] This embodiment provides a controller, including the synchronous rocker sensor of Embodiment 1 or Embodiment 2, which has the advantages of long service life, miniaturization, good synchronization, and sensitive automatic reset.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com