A cable slicer

A slicer and cable technology, applied in metal processing, measuring devices, instruments, etc., can solve problems such as unfavorable inspection, influence on insulation thickness test data, high accident rate, etc., improve cutting efficiency and cutting accuracy, and meet the needs of large-scale inspection , Economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

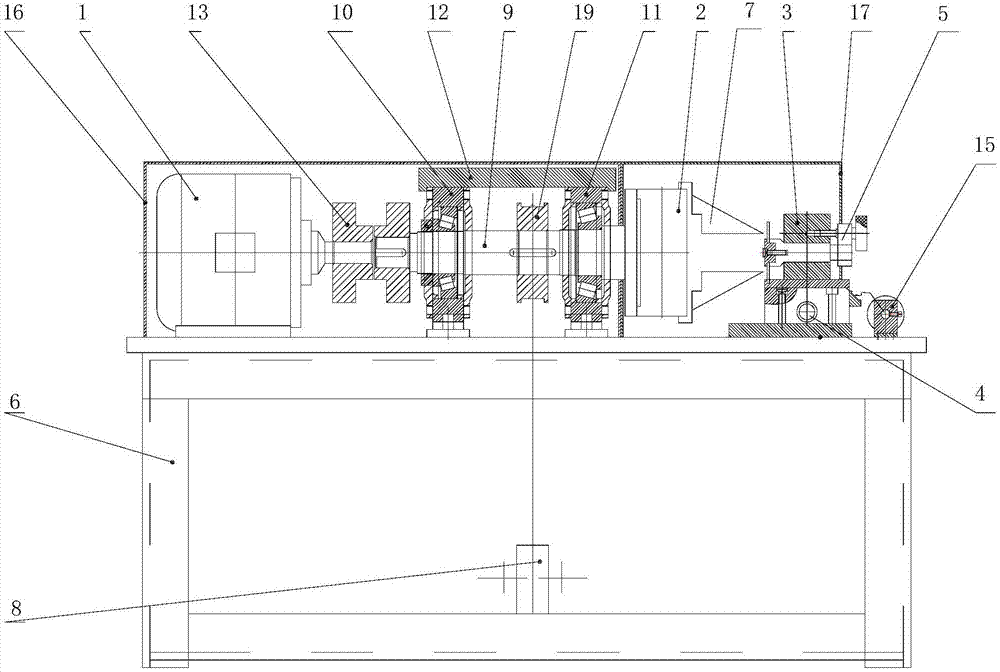

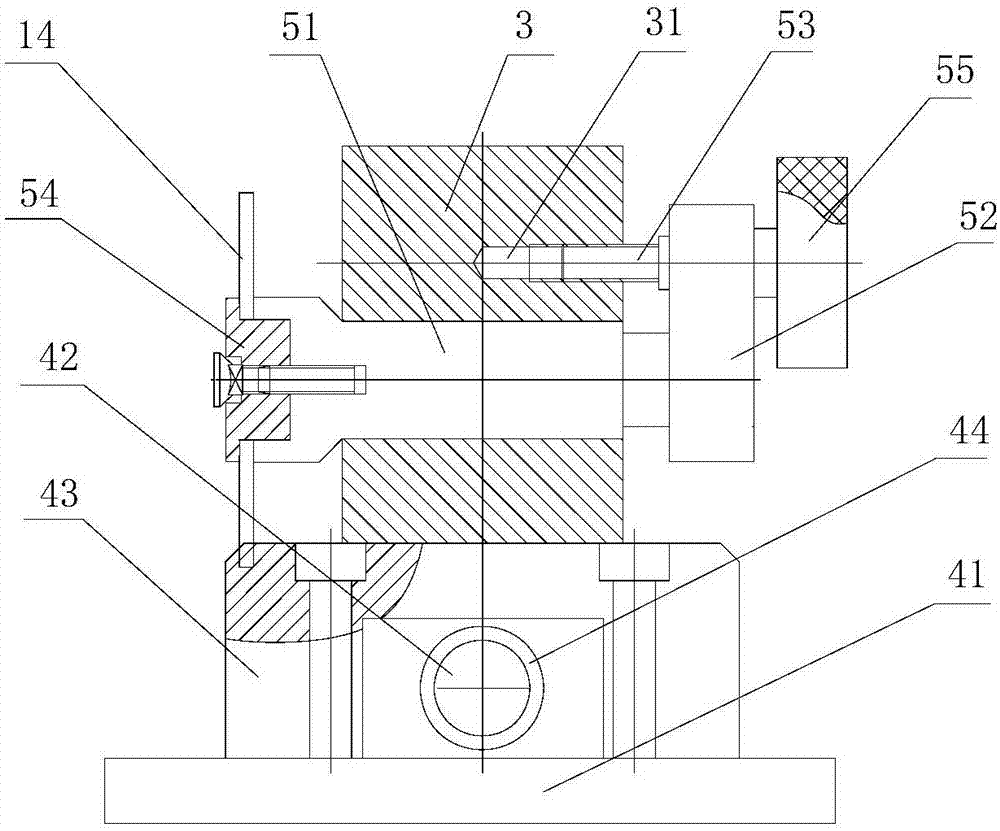

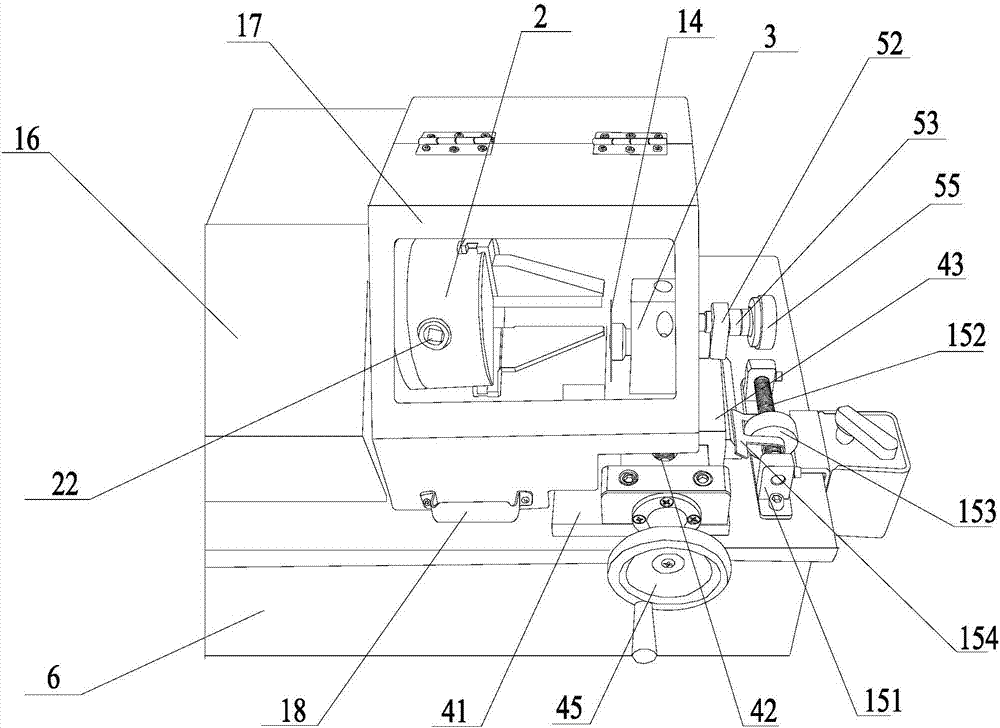

[0020] Such as figure 1 As shown, a cable slicing machine includes a motor 1, a transmission device, a chuck 2, a cutter device, a transverse mechanism 4, and a longitudinal mechanism 5. The motor 1 is arranged on a base 6, and the output end of the motor 1 passes The transmission device is connected to the chuck 2 and drives the chuck 2 to rotate. The front end of the chuck 2 is provided with a clamping mechanism 7; the cutting device is correspondingly arranged in front of the chuck 2, and the cutting The knife device includes a knife holder 3 and a circular blade 14 arranged at the rear end of the knife holder 3. The cutting edge of the blade 14 and the rotation axis of the chuck 2 are perpendicular to each other and correspond to the clamping mechanism 7; The mechanism 4 is arranged at the bottom end of the knife holder 3. The transverse mechanism 4 drives the blade 14 to move laterally relative to the chuck 2; the longitudinal mechanism 5 is arranged at the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com