Workpiece clamping device of crystal bar orienting and material bonding machine

A workpiece clamp and sticker technology, applied in the mechanical field, can solve the problems of uneven pressure on the crystal rod, inaccurate sticking, and sticking angle error, so as to achieve intelligent and controllable pressure application, fast and convenient installation, and avoid errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

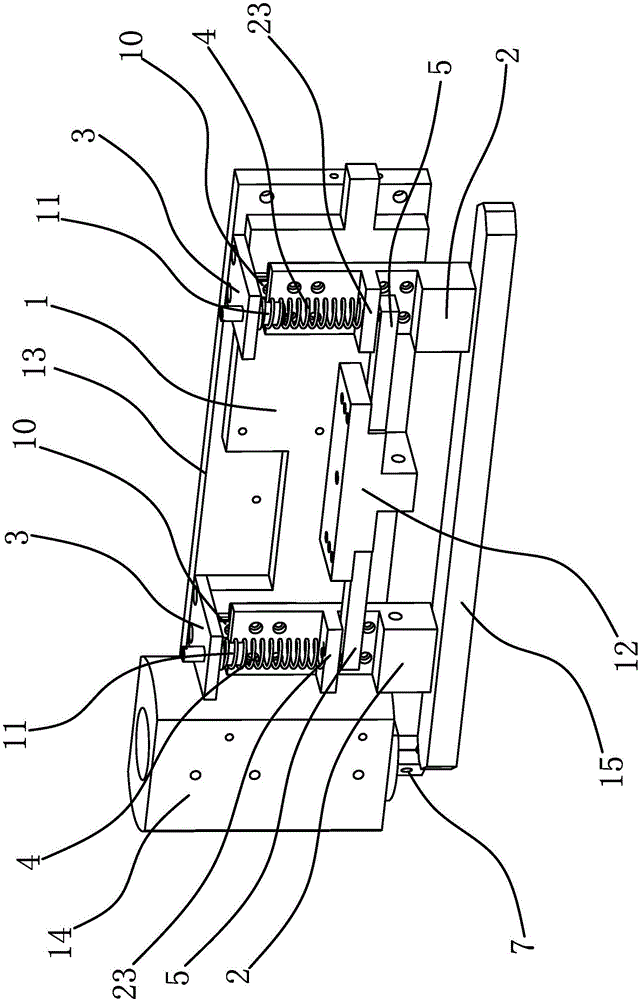

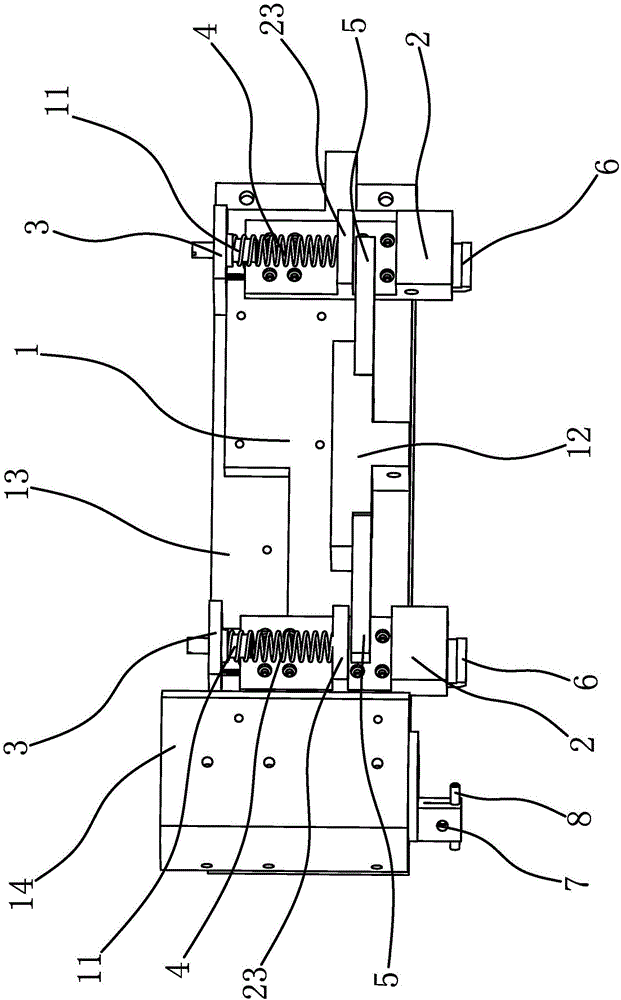

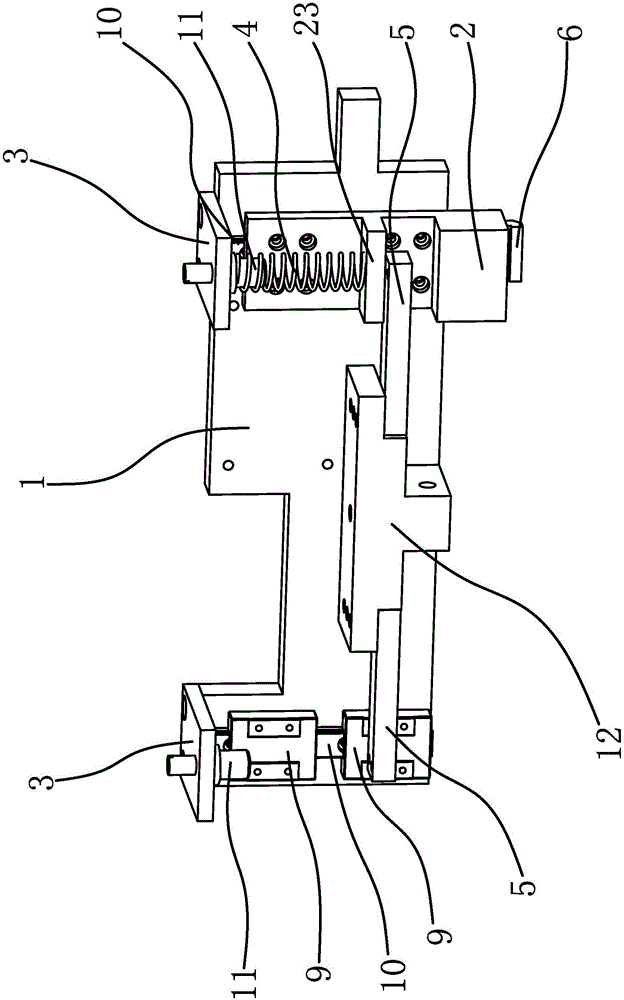

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0024] The workpiece clamping device of this crystal rod directional adhesive machine includes a clamp substrate 1, a vacuum suction head 2, a suction hole 2a, an air outlet 2b, a body 21, a suction head 22, a connecting portion 23, a spring pressure plate 3, a spring 4, a pressure Sensor 5, positioning side plate 6, thimble seat 7, thimble 8, slider 9, slide rail 10, spring pressure head 11, sensor mounting seat 12.

[0025] Specifically, as figure 1 As shown, the workpiece clamping device includes a fixture base plate 1 on which a strip-shaped vacuum suction head 2 capable of sliding in a vertical direction is slidably connected. There are two vacuum suction heads 2 and their positions correspond to the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com