Plastic garbage fast chopping device for feed plant

A technology of plastic waste and shredding device, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of poor shredding effect, complex structure, low work efficiency, etc., to improve the work efficiency of enterprises, good shredding effect, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

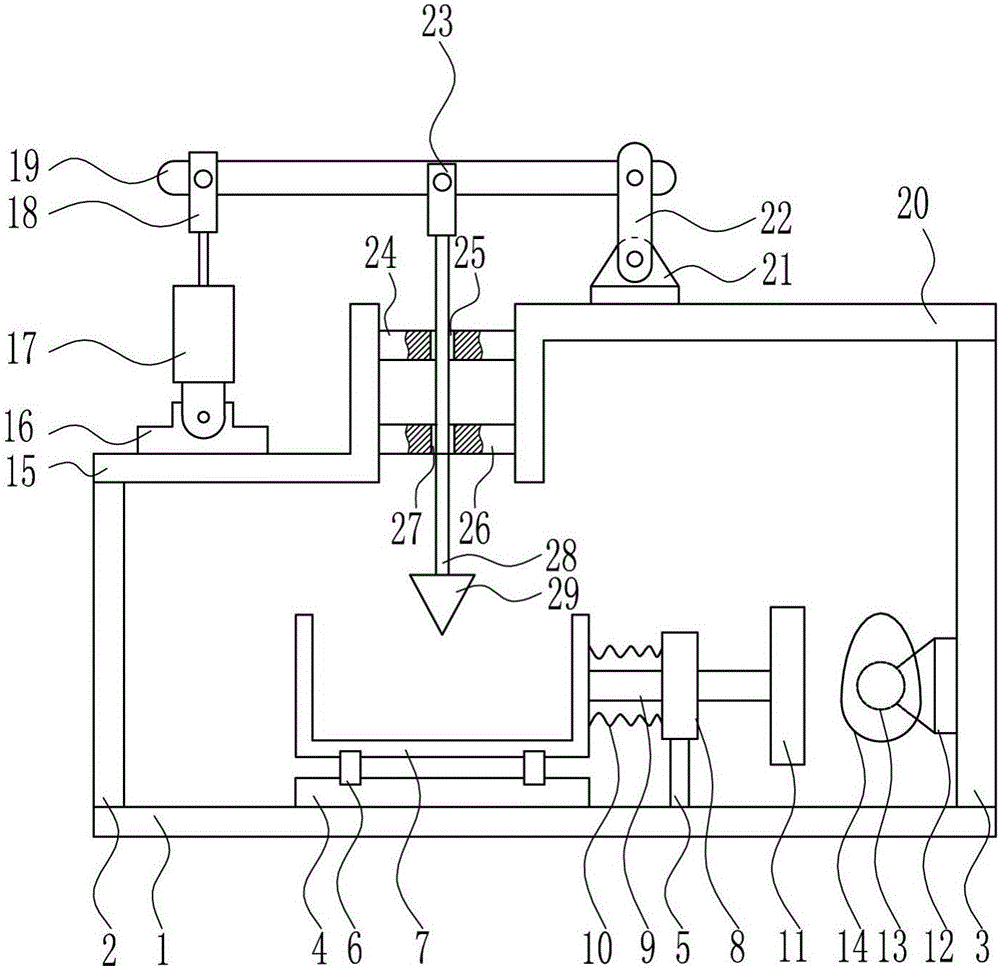

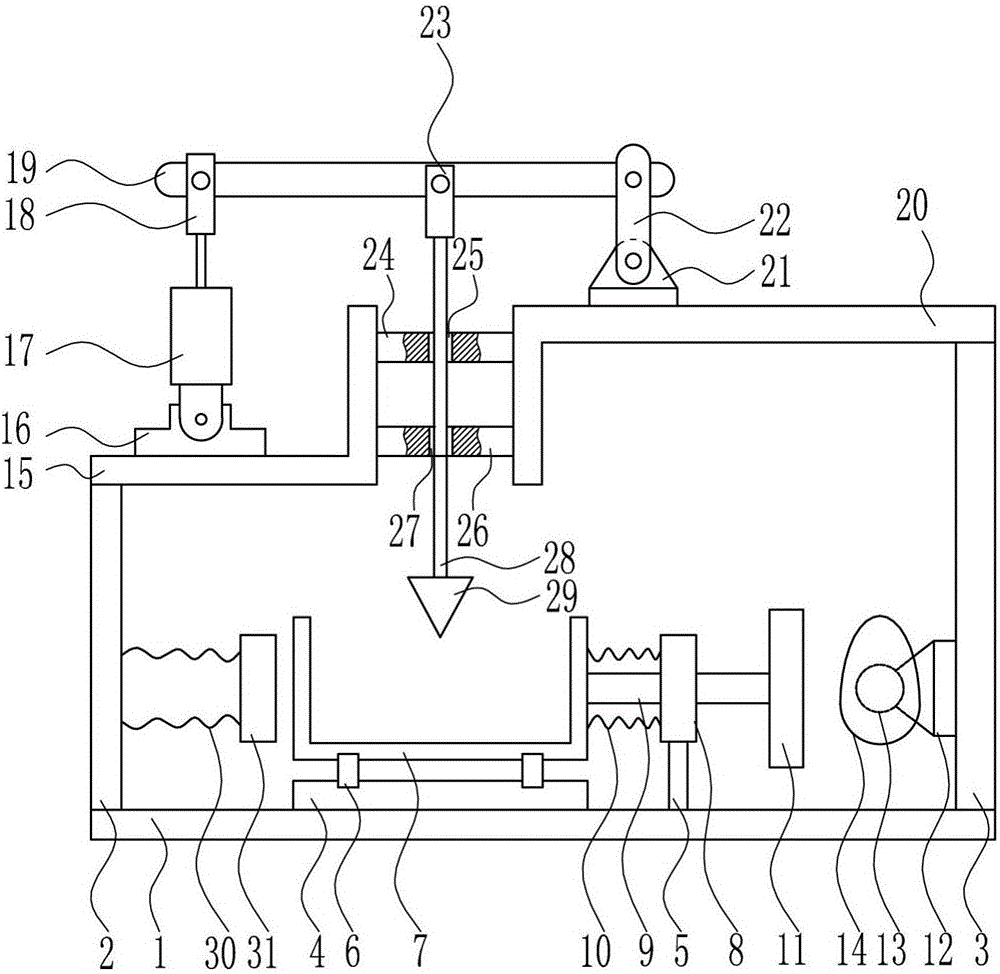

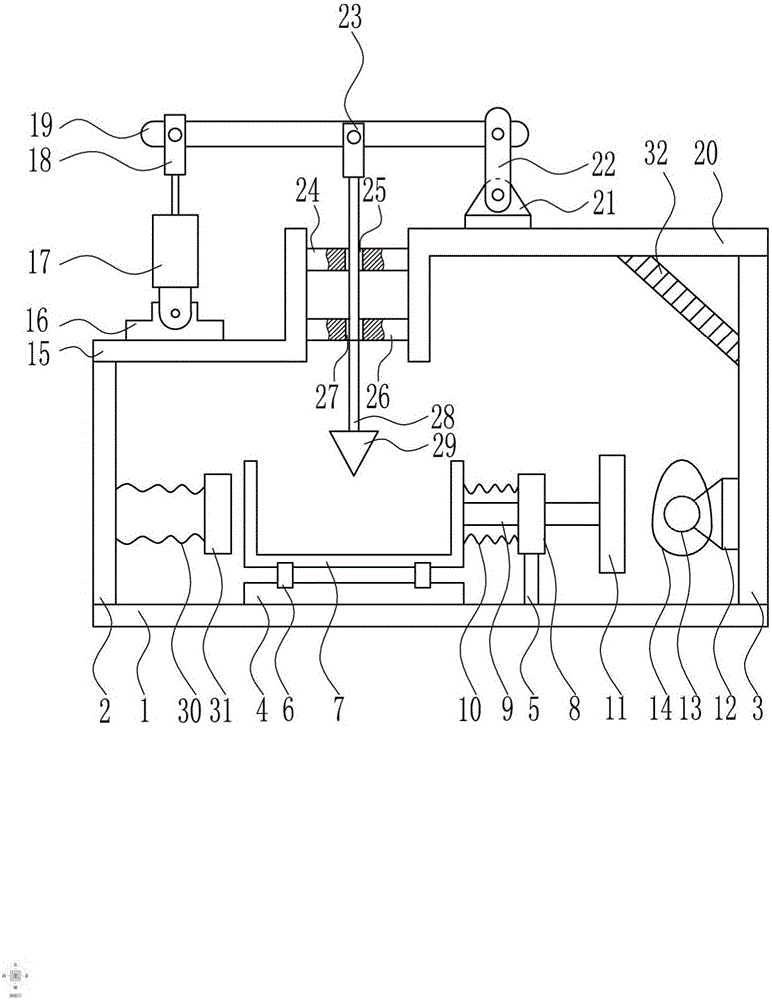

[0027] A fast shredding device for plastic waste in a feed factory, such as Figure 1-3 As shown, it includes base plate 1, left frame 2, right frame 3, slide rail 4, pole 5, slider 6, shredding frame 7, guide sleeve 8, guide rod 9, first spring 10, striking plate 11, First mounting seat 12, motor 13, cam 14, first L-shaped fixed plate 15, swing seat 16, cylinder 17, first connecting block 18, connecting rod 19, second L-shaped fixed plate 20, fixed seat 21, connection Bar 22, second connecting block 23, first guide plate 24, second guide plate 26, lifting rod 28 and cutter 29, bottom plate 1 top is provided with left frame 2, slide rail 4, pole 5 successively from left to right And right frame 3, sliding type is connected with slide block 6 on slide rail 4, is provided with shredding frame 7 on slide block 6, is provided with the first spring 10 symmetrically outside the right wall of shredding frame 7, and pole 5 tops are provided with guide. Cover 8, two first springs 10 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com