Automobile windshield

A technology for windshields and automobiles, applied in windshields, glass/slag layered products, vehicle parts, etc., can solve the problems of easy peeling of glass fragments, injury to people in the car, poor UV protection, etc., to protect human health. , Improve economic performance, good seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

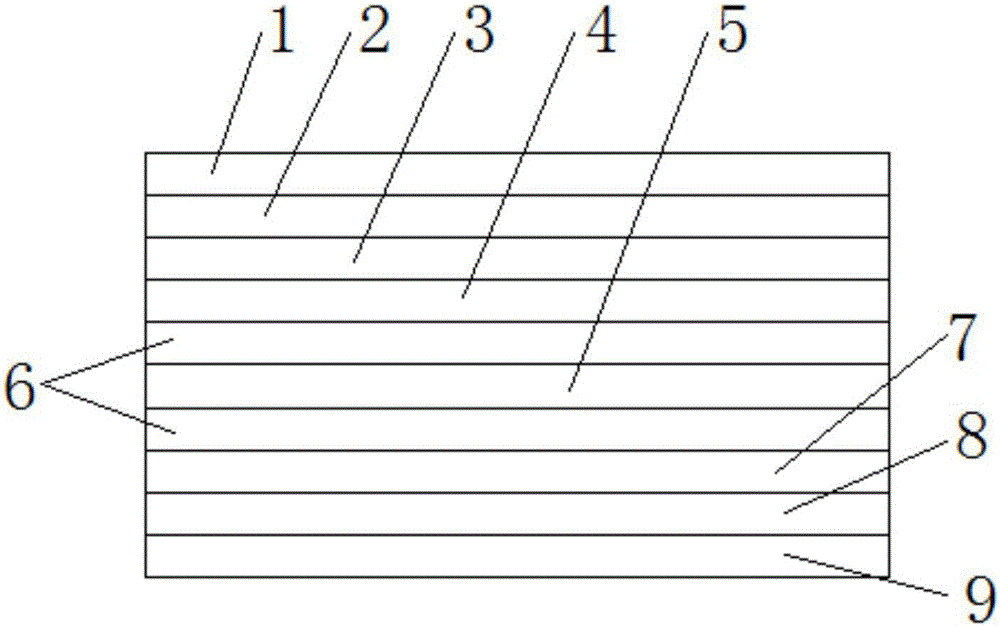

[0020] Example: see figure 1 , a kind of automobile windshield of the present invention, comprises hydrophobic layer 1, buffer layer 2, heat insulation layer 3, first toughened glass 4, vacuum glass 5, transparent damping film 6, second toughened glass 7, safety layer 8 and water-absorbing Layer 9, the hydrophobic layer 1 is bonded to the buffer layer 2, the buffer layer 2 is bonded to the heat insulating layer 3, and the heat insulating layer 3 is made of 2-hydroxyl-4-methoxybenzophenone, ortho Butyl phthalate and zinc oxide are compounded, and the heat insulation layer 3 is pasted on one side of the first tempered glass 4, and the first tempered glass 4 is connected with the second tempered glass 7 through the vacuum glass 5 And the transparent damping film 6 is bonded between them, and the inside of the vacuum glass 5 is filled with a rare gas. One side of the second tempered glass 7 is bonded with a safety layer 8, and one side of the safety layer 8 is connected to the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com