A liquid spray head, a nozzle plate used for the liquid spray head and a manufacturing method of the nozzle plate

A technology of liquid nozzles and manufacturing methods, which is applied in printing and other directions, and can solve the problems of uncontrollable ink droplet size, inaccurate control of quantum dot film thickness, inconsistent ink droplet size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

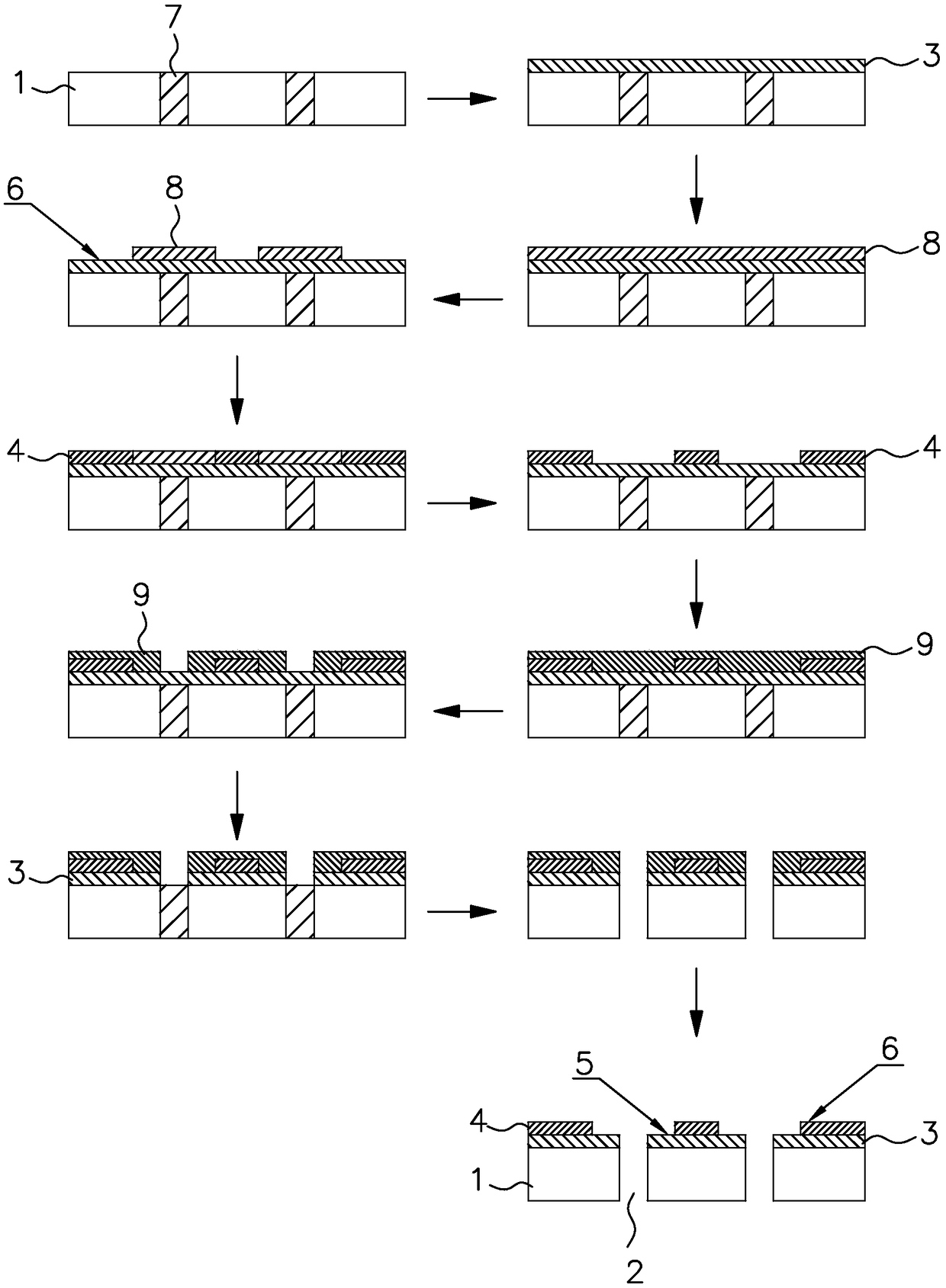

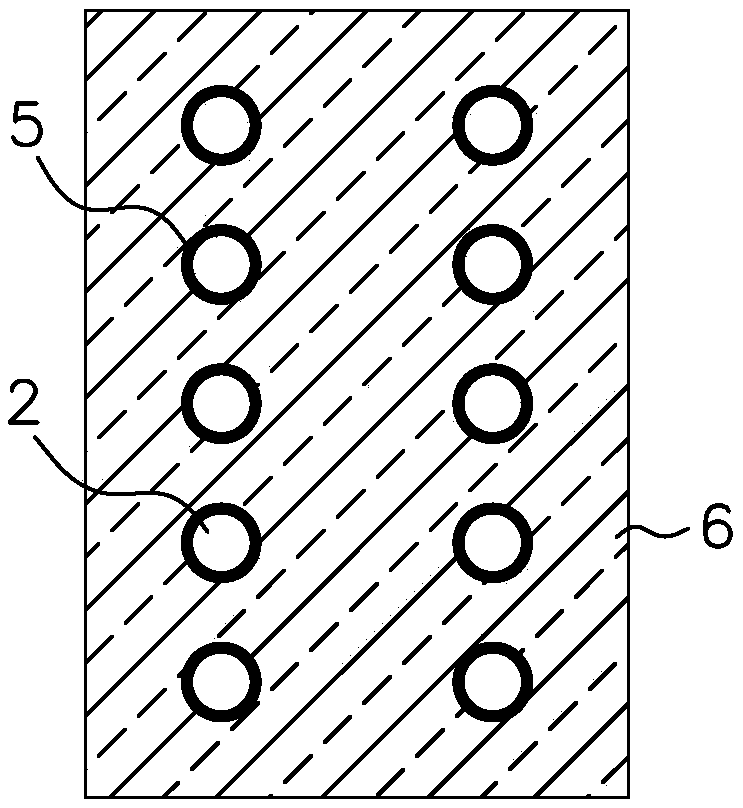

[0088] like figure 2 and image 3 As shown, the present embodiment is used for the nozzle plate of the liquid spray head, including the plate body 1, which is provided with at least one nozzle opening 2; the liquid outlet side of the plate body 1 is provided with a hydrophilic film 3 and a hydrophobic Membrane 4, but at the outer edge of the nozzle opening 2, the hydrophobic membrane 4 does not cover the hydrophilic membrane 3, and the hydrophilic membrane 3 forms a hydrophilic area surface 5 because it is exposed on the outside, and other areas covered by the hydrophobic membrane 4 The surface 6 of the hydrophobic region is then formed.

[0089] The manufacture method of above-mentioned nozzle plate comprises the following steps (flow chart as figure 2 ):

[0090] (1) Get a conventional nozzle plate provided with nozzle openings, and fill each nozzle opening with a filler (polysilicon is used in this embodiment);

[0091] (2) Set a hydrophilic film on the liquid outlet ...

Embodiment 2

[0102] like Figure 4 and Figure 5 As shown, the nozzle plate used in this embodiment for the liquid nozzle includes a plate body 1, and at least one nozzle opening 2 is provided on the plate body 1; an oleophilic film 11 and an oleophobic film are sequentially provided on the surface of the plate body on the liquid outlet side. 10, but at the outer edge of the nozzle opening 2, the oleophobic film 10 does not cover the oleophilic film 11, and the oleophilic film 11 forms the surface 12 of the oleophilic area because it is exposed on the outside, and other areas covered by the oleophobic film 10 form a The surface 13 of the oleophobic area; in addition to the surface 12 of the oleophilic area and the surface 13 of the oleophobic area, there is also a blank area 14 on the surface of the plate body on the liquid outlet side.

[0103] The manufacturing method of the above-mentioned nozzle plate comprises the following steps:

[0104] (1) Get a conventional nozzle plate provide...

Embodiment 3

[0117] like Image 6 As shown, the nozzle plate used in this embodiment for the liquid spray head includes a plate body 1, and at least one nozzle opening 2 is provided on the plate body 1; The surface 12 of the lipophilic region on the outer edge, and the surface 13 of the oleophobic region on the periphery of the surface 12 of the lipophilic region, wherein the corresponding position of the surface 12 of the lipophilic region is covered with an oleophilic film 11, and the corresponding position of the surface 13 of the oleophobic region The inside is covered with an oleophobic film 10 , and the thickness of the oleophobic film 10 is greater than the thickness of the oleophilic film 11 .

[0118] The manufacture method of above-mentioned nozzle plate comprises the following steps (its flow chart is as follows Image 6 ):

[0119] (1) Take a conventional nozzle plate provided with nozzle openings, and fill each nozzle opening with a filler (amorphous silicon is used in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com