Novel hub for tubeless wheel

A new type of hub technology, applied in the direction of wheels, wheel accessories, rims, etc., can solve the problems of affecting the dynamic balance of the wheel, weakening the friction between the hub and the tire, and difficult installation, so as to prevent the brake and steering from being out of control after a tire blowout. Good performance and reliability, and the effect of improving the strength of the hub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

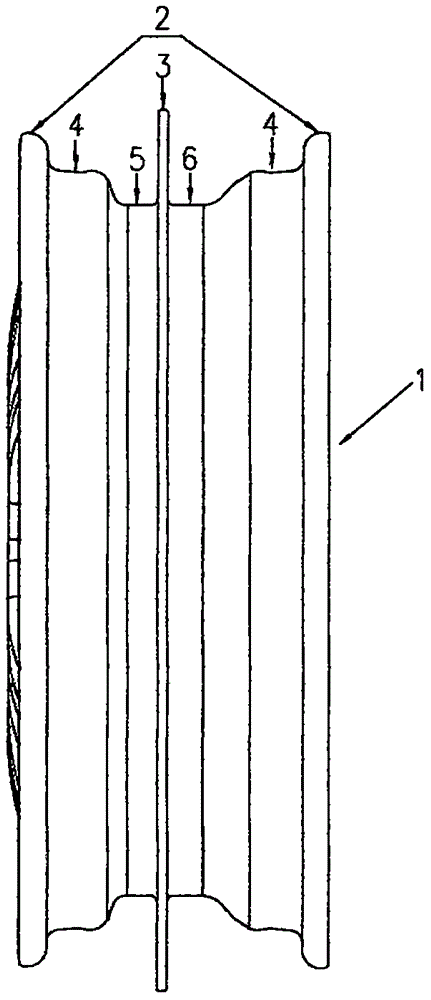

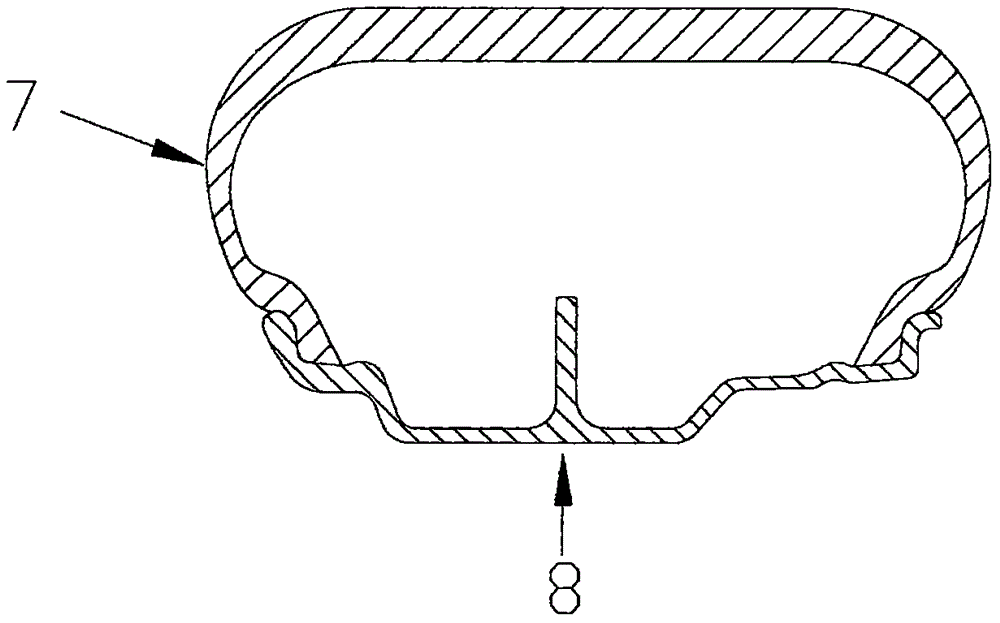

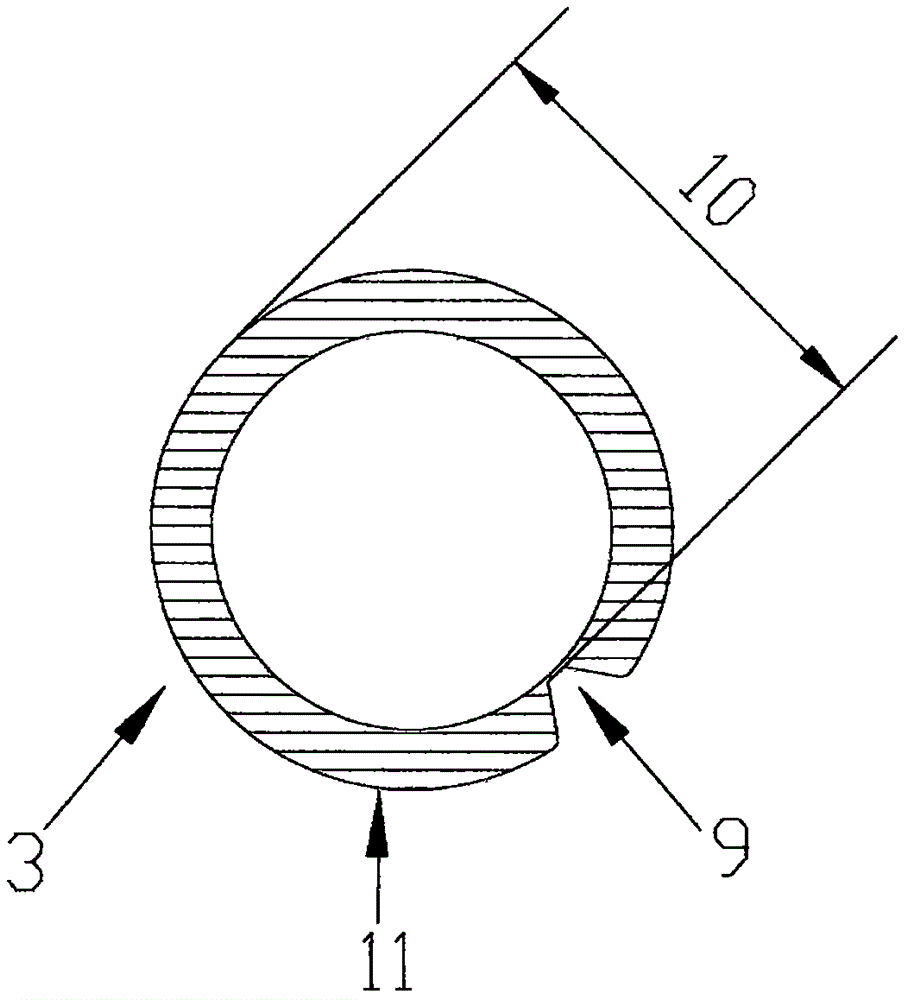

[0023] This embodiment provides a novel wheel hub for tubeless wheels, such as figure 1 , figure 2 , image 3 As shown, the annular support rib 3 is arranged on the inner surface of the rim between the two rims 2, and is made of an integral molding process with the new hub 1 of the tubeless wheel, and the material of the new hub 1 of the inner tube wheel is aluminum alloy, or Magnesium alloy, or carbon fiber; the left side of the annular support rib 3 is provided with a tire installation process groove 5, the right side is provided with a tire installation process groove 6, the annular support rib 3 is provided with a tire installation process gap 9, and the annular support rib is ring-shaped The surface 11 is rough, and the maximum distance 10 from the bottom of the notch in the tire installation process to the annular support rib is smaller than the diameter of the rim 2 .

[0024] Tubeless tire 7 During installation, such as figure 2 As shown, the tubeless tire 7 is in...

Embodiment 2

[0030] This embodiment provides a new type of hub for tubeless wheels, the difference from Embodiment 1 is that, as Figure 4 The annular surface 11 of the annular support rib 11 is provided with a plurality of notches 12 to form a sawtooth structure 13, and the sawtooth structure 13 of the annular support rib 3 can engage with the inner surface of the flattened tubeless tire 7.

Embodiment 3

[0032] This embodiment provides a new wheel hub for tubeless wheels. The difference from Embodiment 1 and Embodiment 2 is that the annular support rib 3 and the new wheel hub 1 of the tubeless wheel are welded into one by welding process. The material of the novel wheel hub 1 is steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com