Ice and snow road car tires

A car tire, ice and snow technology, applied to road vehicle tires, road vehicles, tire parts, etc., can solve the problems of increased braking distance and skidding, and achieve the effects of maintaining rigidity, reducing environmental pollution, and increasing ground contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

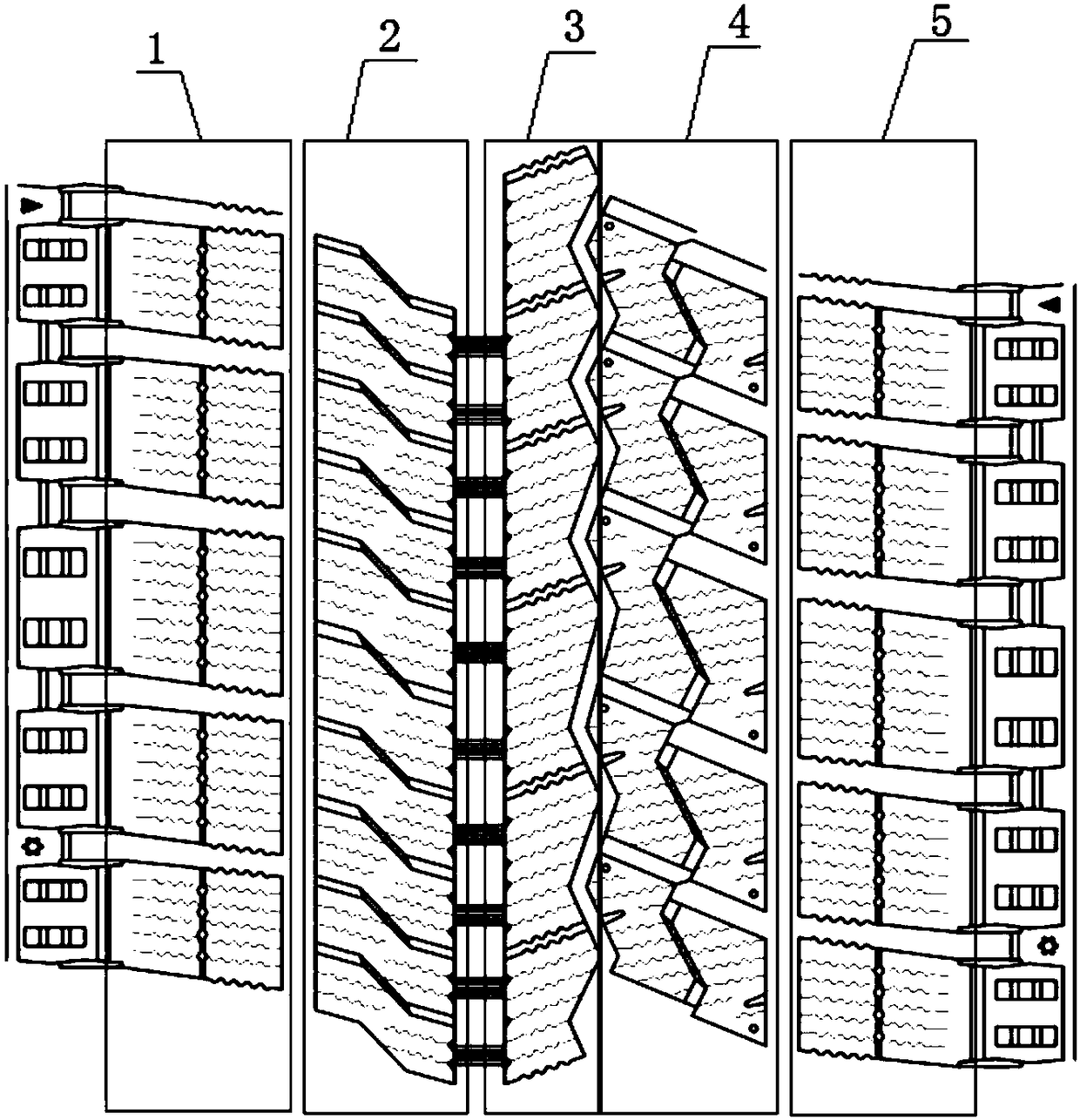

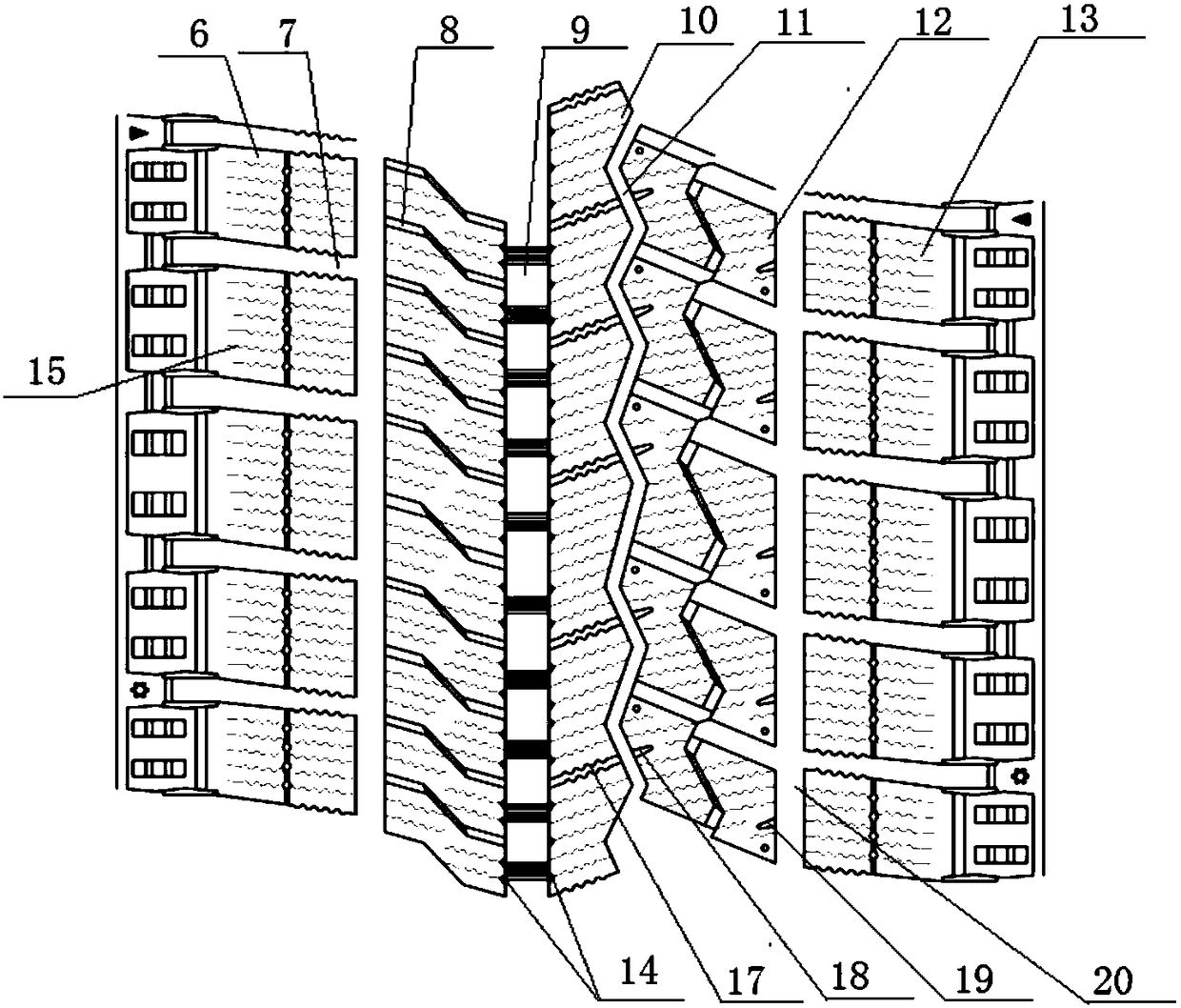

[0019] like figure 1 As shown, the tread pattern of the car tire on ice and snow roads includes an inner shoulder pattern 1, an inner middle pattern 2, a middle pattern 3, an outer middle pattern 4 and an outer shoulder pattern 5, wherein the middle pattern 3 is located between the inner middle pattern 2 and the outer shoulder pattern 5. Between the outer middle patterns 4 , the inner shoulder patterns 1 are located outside the inner middle patterns 2 , and the outer shoulder patterns 5 are located outside the outer middle patterns 4 . The inner shoulder pattern 1 is provided with an inner shoulder pattern block 6, and an inner shoulder transverse pattern groove 7 is formed between each inner shoulder pattern block 6. The inner middle pattern 2 includes a plurality of Z-shaped pattern blocks, which make the tread of the tire adhere to the road surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com