Full-automatic plate overturning machine

A flipping machine, fully automatic technology, applied in the direction of lifting device, hoisting device, etc., can solve the problems of broken or damaged, easily broken or damaged, time-consuming, etc., to reduce labor costs, improve production efficiency, and have no potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

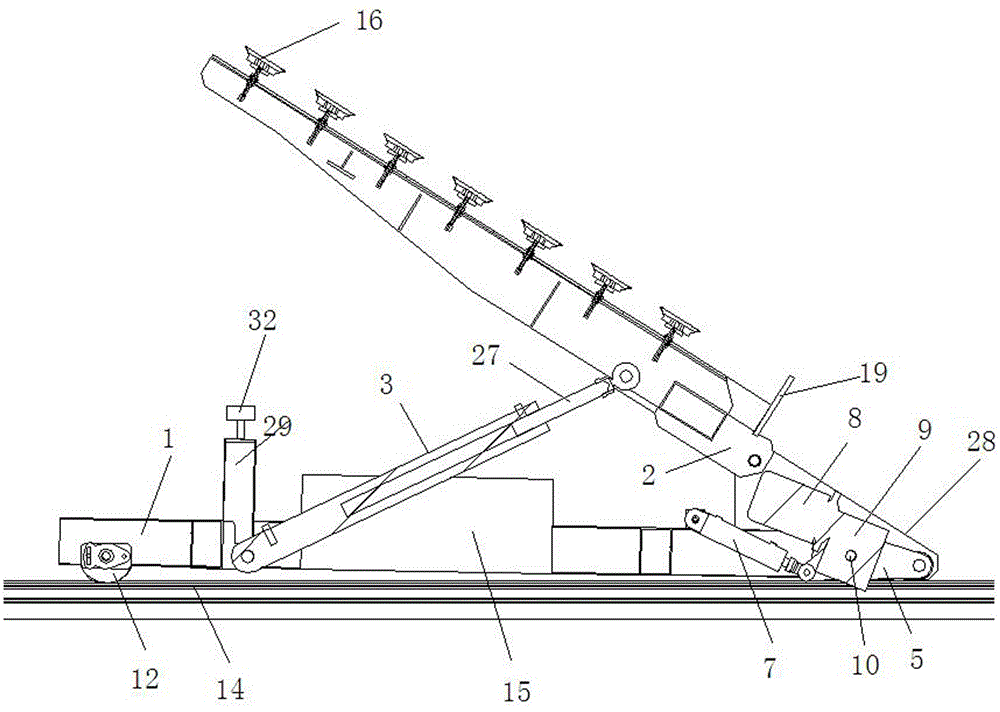

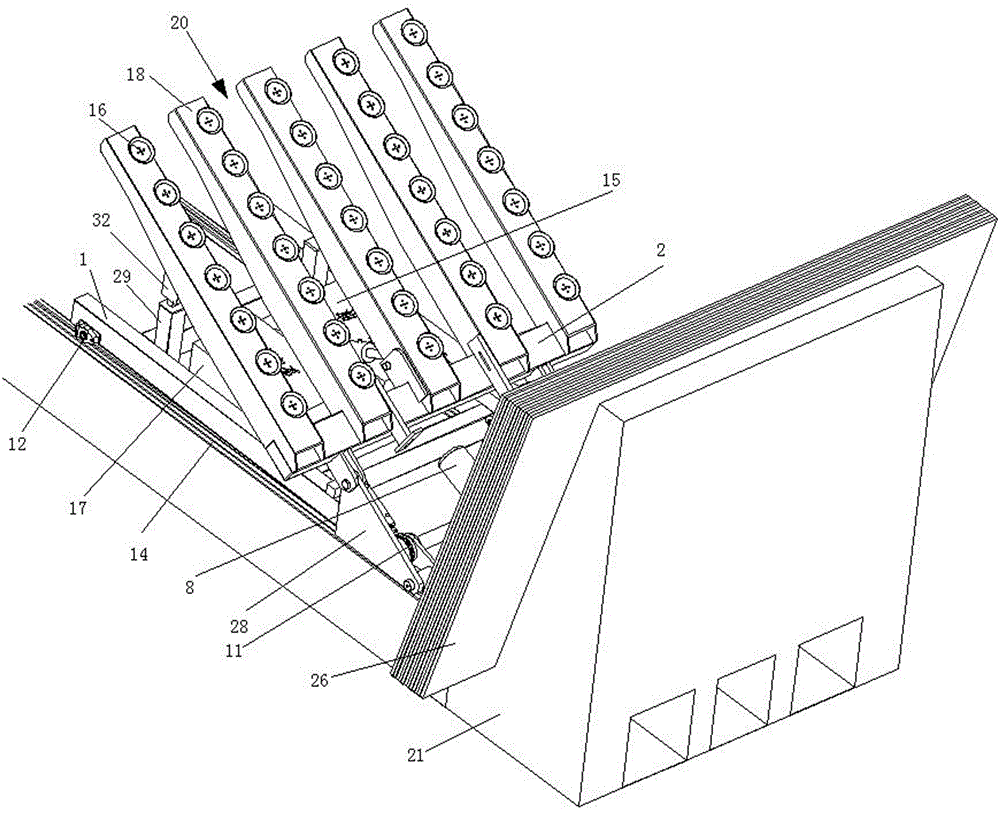

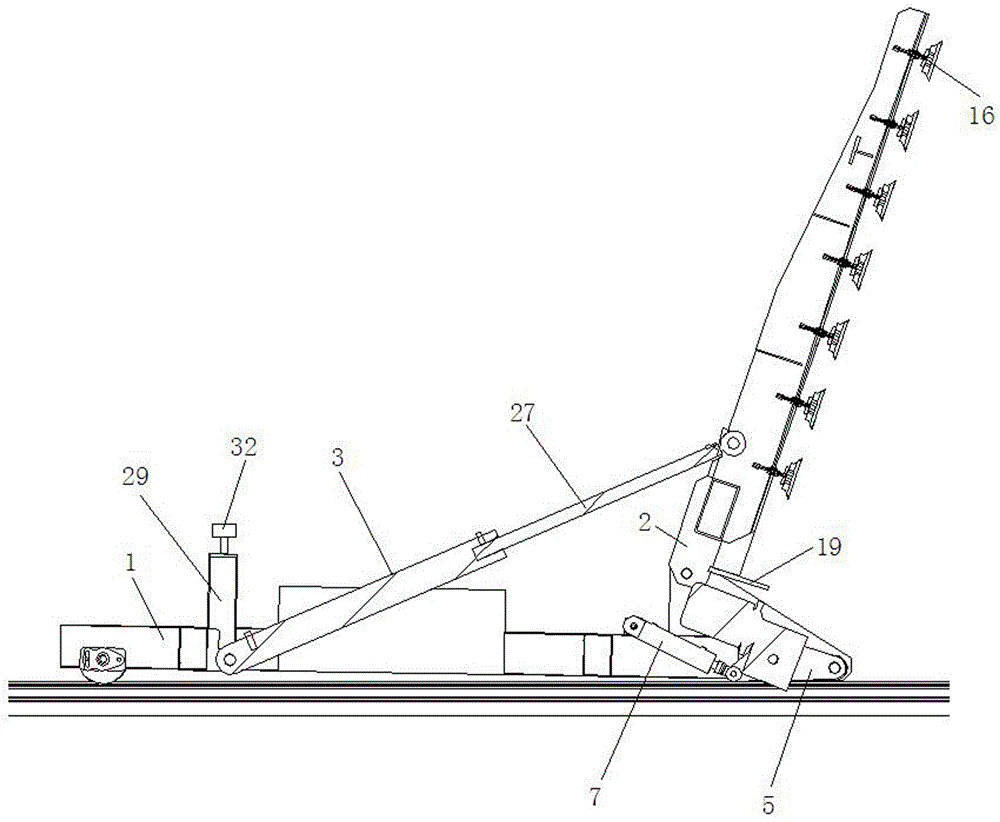

[0032] Fully automatic turning machine, such as Figure 1 to Figure 14 As shown, it includes a walkable underframe 1 , an overturn frame 2 , a turnover plate cylinder 3 , a swing arm assembly, a suction plate assembly, a walking device for driving the underframe 1 , and a transition table 22 .

[0033] The front part of the bottom frame 1 is fixedly provided with a connecting plate 28 , and the swing arm assembly and the turning frame 2 are connected to the bottom frame 1 through the connecting plate 28 . The longitudinal section of the connecting plate 28 is a right triangle, and the right-angled end of the connecting plate 28 is fixedly connected with the front end of the chassis 1. Both sides of the front part of the underframe 1 are provided with connecting plates 28 . Underframe 1 is fixedly provided with the support bar 29 that is used to support turning frame 2, and support bar 29 upper end is provided with elastic stopper 32 or support bar 29 tops is the stopper 32 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com