Clay checker brick and preparation method thereof

A technology of checker bricks and clay, applied in the field of refractory materials, can solve the problems of uneven product density, product pitting, affecting appearance, etc., and achieve the effect of firm skeleton structure, simple preparation steps, and reasonable composition matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

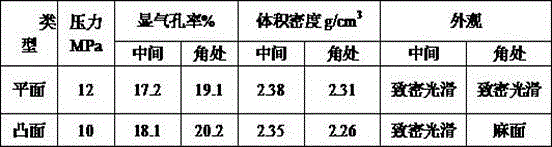

Examples

Embodiment 1

[0015] This embodiment provides a clay checker brick, a clay checker brick, which includes a main material and a binder, and the quality of the binder is 3.5% of the weight of the main material. The main ingredients include the following raw materials in mass percentages: 40% of large clay clinker particles, 25% of small clay clinker particles, and 35% of clay fine powder. Wherein, the clay fine powder is composed of clay clinker fine powder and soft clay fine powder with a mass ratio of 1:2.5; the binder is an aqueous solution of calcium lignosulfonate with a density of 1.14 g / mL. The particle size of the large clay clinker particle is 1.0 mm to 2.0 mm; the particle size of the small clay clinker particle is 0.5 mm to 1.0 mm; the particle size of the clay fine powder is less than 0.088 mm.

[0016] This embodiment also provides a method for preparing the above-mentioned clay checker brick, the steps of which include: mixing large clay clinker particles, clay clinker small par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com