Quenching smoke-removing device with vertical low-resistance cooling system

A cooling system, low-resistance technology, applied in coke cooling, coke oven, furnace prevention/removal of fouling, etc., can solve problems such as waste of water resources, environmental pollution, etc. Guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the drawings.

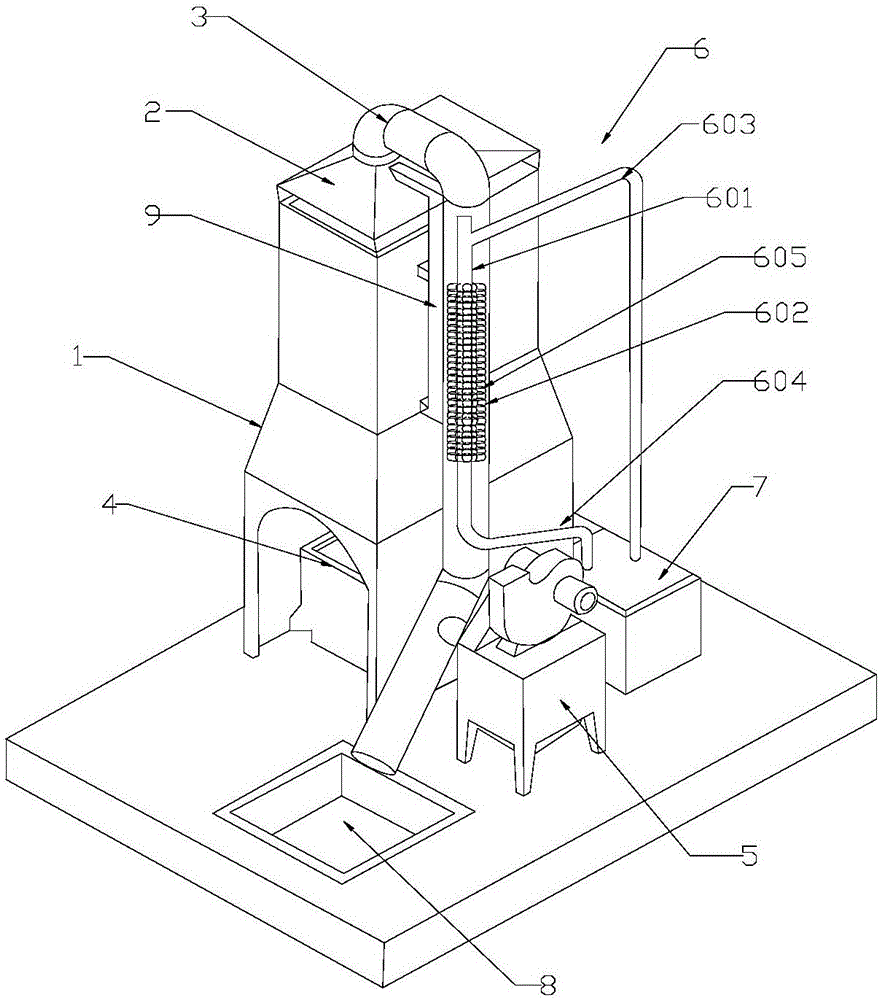

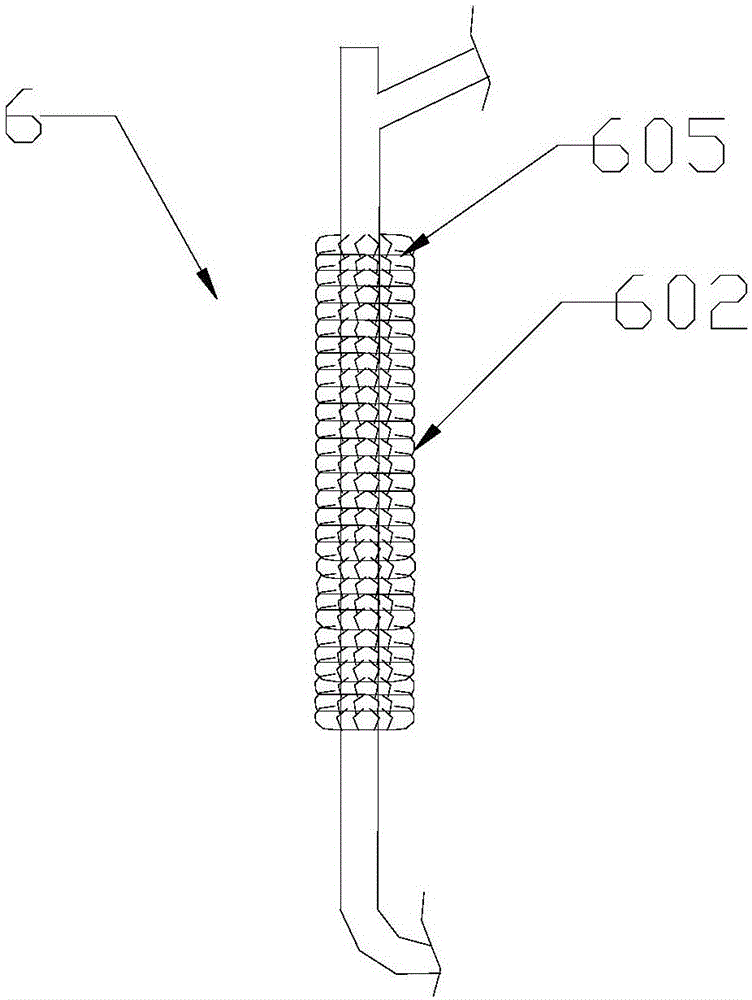

[0010] Figure 1 ~ Figure 2 Schematically shows a coke quenching and smoke removal device with a vertical low-resistance cooling system, including a coke quenching tower 1, a collection cover located above the quenching tower 1, a quenching car 4 located in the quenching tower 1, and The outer shell tube 3 connected to the collecting cover 2 is connected to the quenching tower 1 through a bracket 9. A vertical low-resistance cooling system 6 is vertically fixed in the shell tube 3, a dust collector 5 is connected to the side wall of the shell tube 3, and the water outlet of the shell tube 3 is connected to the waste water tank 8. The vertical low-resistance cooling system 6 includes a cooling tube 601, The inlet end of the cooling pipe 601 communicates with one end of the cooling liquid inlet pipe 603, the outlet end of the cooling pipe 601 communicates with one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com