Microbial fermentation device

A technology of microbial fermentation and reaction chamber, applied in the field of machinery to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The invention designs a small-scale simulated experimental device capable of degrading cyanobacterial organic matter through microbial aerobic and anaerobic degradation. This device can realize microbial aerobic and anaerobic degradation transformation of cyanobacteria organic matter, effectively produce humified organic matter, and can also collect gas products during the degradation process of cyanobacteria, providing suitable simulated samples for modern organic matter hydrocarbon generation evolution experiments , in order to carry out hydrocarbon generation simulation experiments close to geological reality.

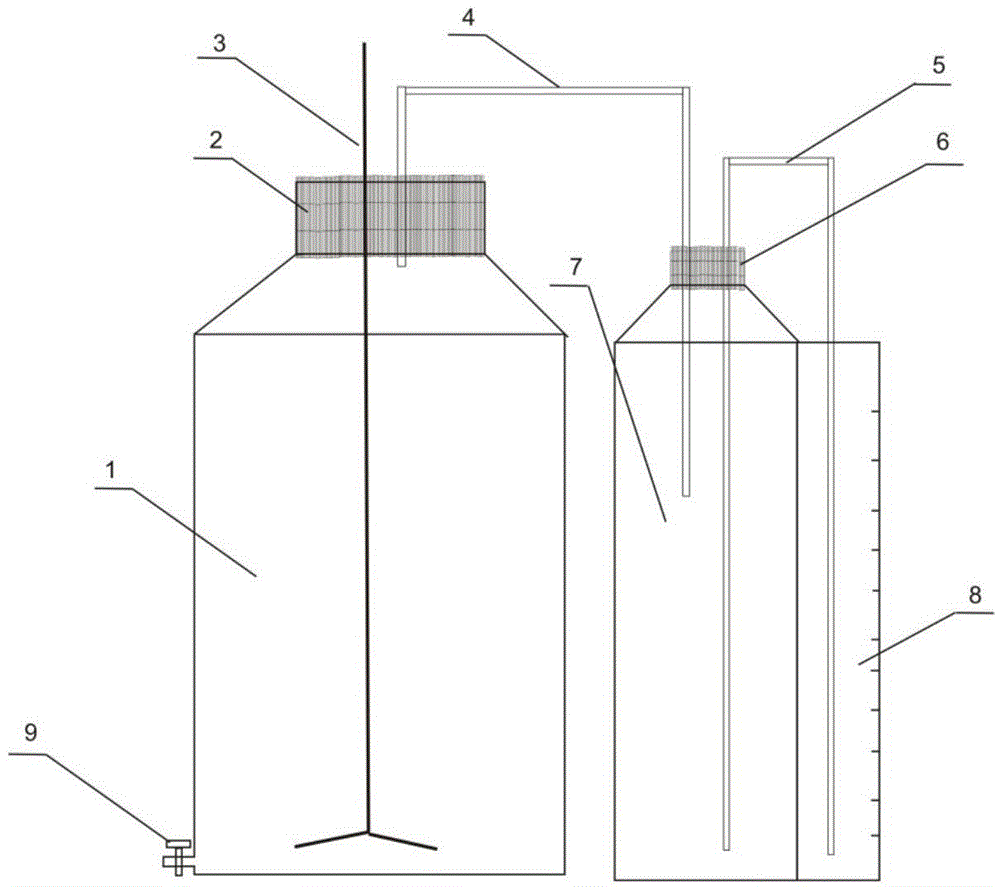

[0024] like figure 1 Shown is a small-scale simulation experimental device for microbial degradation of cyanobacteria organic matter, which at least includes the following components, a reaction chamber 1 with a reaction chamber port, a reaction chamber cover 2 used in conjunction with the reaction chamber port, and the reaction chamber cover 2 is provided w...

Embodiment 2

[0039] A small-scale simulation experiment of microbial degradation of cyanobacterial organic matter

[0040] The working process of the small-scale simulation experiment device for microbial degradation of cyanobacteria organic matter is:

[0041] 1) Place the cyanobacteria sample collection in the reaction chamber 1, fill the cyanobacteria, and carry out cell disruption to the cyanobacteria (the crushing of the cyanobacteria can also be carried out before loading into the reaction chamber) to obtain the cyanobacteria fragmentation mixture. At this time, there is no need to plug Tighten the reaction chamber cover 2 made of polytetrafluoroethylene, install the stirrer 3 and then stir, and carry out the natural hydrolysis process according to the microbial transformation plan. During this process, there is no need to collect gas, therefore, at this time, the reaction chamber 1 and the first container 7 are not connected through the first conduit 4 temporarily.

[0042] 2) Inoc...

Embodiment 3

[0050] Small-scale simulation experiment of microbial degradation of various algae organic matter

[0051] 1) Hydrolysis stage: Put the fresh algae into the simulation device, use the temperature control device to control the temperature of the reaction chamber 1 to a constant temperature of 37°C, and hydrolyze for 7 days.

[0052] 2) Aerobic stage: inoculate the hydrolyzed algae with desulfurization bacteria, and desulfurize under aerobic conditions for 30 days. The microorganisms can convert sulfur into sulfate under aerobic conditions. and polythiosulfate to obtain energy.

[0053] 3) Anaerobic stage: the aerobic treated cyanobacteria were fed into argon to form an anaerobic environment, inoculated with nitrate-reducing bacteria for 7 days; then inoculated with sulfate-reducing bacteria for anaerobic treatment for 70 days, and the processed product was filtered Dry too much water, transfer to a freeze dryer, and dry to obtain humified organic matter that can be used to car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com