A kind of preparation method of modified camellia oil fatliquor for leather processing

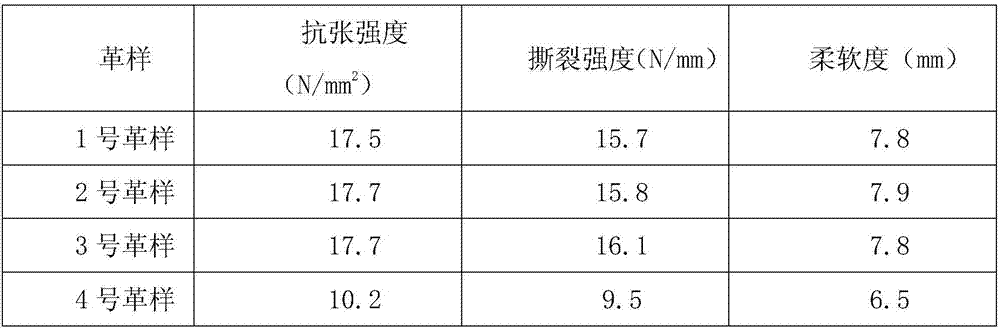

An oil fatliquoring agent and camellia oil technology, which is applied in the preparation field of modified camellia oil fatliquoring agent, can solve the problems of few applications of carbon nanotubes and the like, achieve easy control of preparation process conditions, low equipment requirements, and improved resistance to Effect of Tensile Strength and Tear Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for a modified camellia oil fatliquoring agent for leather processing, comprising the following steps:

[0025] a. Take 850 parts by mass of camellia oil, 147 parts by mass of n-butanol and 3 parts by mass of catalyst into the reactor; react at 100-120°C for 2-3 hours, measure the hydroxyl value in the reaction system, and use the total amount of reactants Quantitatively, when the hydroxyl value ≥ 65mg KOH / g, the unreacted butanol was distilled off under reduced pressure.

[0026] b. Add 120 parts by mass of concentrated sulfuric acid dropwise to the reaction product. When adding the concentrated sulfuric acid, control the temperature to ≤30°C. After the dropwise addition, react at 35-40°C for 2-3 hours.

[0027] c. Add 1000 parts by mass of saturated saline to the reaction product, mix well, transfer to a separatory funnel and let stand for 4-6 hours.

[0028] d. Follow the above step c, carry out liquid separation treatment, neutralize the reacta...

Embodiment 2

[0036] A preparation method for a modified camellia oil fatliquoring agent for leather processing, comprising the following steps:

[0037] a. Add 900 parts by mass of camellia oil, 148 parts by mass of n-butanol and 7 parts by mass of catalyst into the reactor; Quantitatively, when the hydroxyl value ≥ 65mg KOH / g, the unreacted butanol was distilled off under reduced pressure.

[0038] b. Add 160 parts by mass of concentrated sulfuric acid dropwise to the reaction product. When adding the concentrated sulfuric acid, control the temperature to ≤30°C. After the dropwise addition, react at 35-40°C for 2-3 hours.

[0039] c. Add 1200 parts by mass of saturated saline to the reaction product, mix well, transfer to a separatory funnel and let stand for 6 hours.

[0040] d. Follow the above step c, carry out liquid separation treatment, neutralize the pH of the reactant to 7.0 with a mass concentration of 20% to 30% alkaline aqueous solution, and adjust the solid content of the pro...

Embodiment 3

[0048] A kind of preparation method of the modified camellia oil fatliquoring agent for leather processing is characterized in that, comprises the following steps:

[0049] a. Take 870 parts by mass of camellia oil, 102 parts by mass of n-butanol and 5 parts by mass of catalyst into the reactor; react at 100-120°C for 2-3 hours, measure the hydroxyl value in the reaction system, and use the total amount of reactants Quantitatively, when the hydroxyl value ≥ 65mg KOH / g, the unreacted butanol was distilled off under reduced pressure.

[0050] b. Add 135 parts by mass of concentrated sulfuric acid dropwise to the reaction product. When adding the concentrated sulfuric acid, control the temperature to ≤30°C. After the dropwise addition, react at 35-40°C for 2-3 hours.

[0051] c. Add 1100 parts by mass of saturated saline to the reaction product, mix well, transfer to a separatory funnel and let stand for 4-6 hours.

[0052] d. Follow the above step c, carry out liquid separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com