Patents

Literature

35results about How to "The preparation process conditions are easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

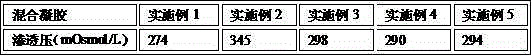

Injection amphiphilic-microsphere-containing hyaluronic acid mixed gel and preparation method thereof

The invention relates to injection amphiphilic-microsphere-containing hyaluronic acid mixed gel and a preparation method thereof. The microsphere material relates to amphiphilic materials of PLLA-PEG, PLGA, PLGA-PEG and the like. The molecular weight of PLLA or PLGA is 10,000-500,000, the molecular weight of PEG is 1,000-10,000, and in PLGA, LA / GA=90 / 10-10 / 90. The average grain diameter of the microsphere is 1-200 [mu[m, and the mass percent of the microsphere in the gel is 1-50%; the gel is made from hyaluronic acid, divinyl sulphone crosslinked hyaluronic acid, or glycidyl ether crosslinked hyaluronic acid, the molecular weight of the hyaluronic acid is 100,000-3,000,000, and the mass percent of the hyaluronic acid is 1-50%. The gel can be also made from animal-derived collagen, chitosan, amino acid cellulose and sodium alginate. The microsphere mixed gel is prepared in a sodium chloride solution or a phosphate buffered solution with the osmotic pressure of 250-350 mOsm / L and pH of 6.5-7.5. According to the invention, the amphiphilic microsphere is directly mixed with hyaluronic acid gel, can be uniformly distributed in the gel easily, and is unlikely to aggregate into blocks in the water environment of a human body after being injected.

Owner:IMEIK TECH DEV CO LTD

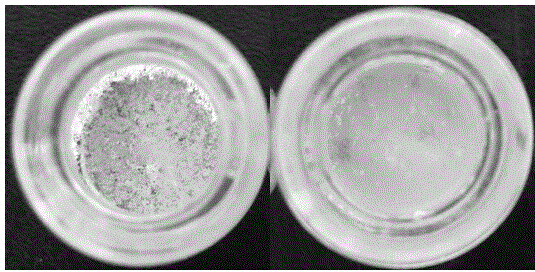

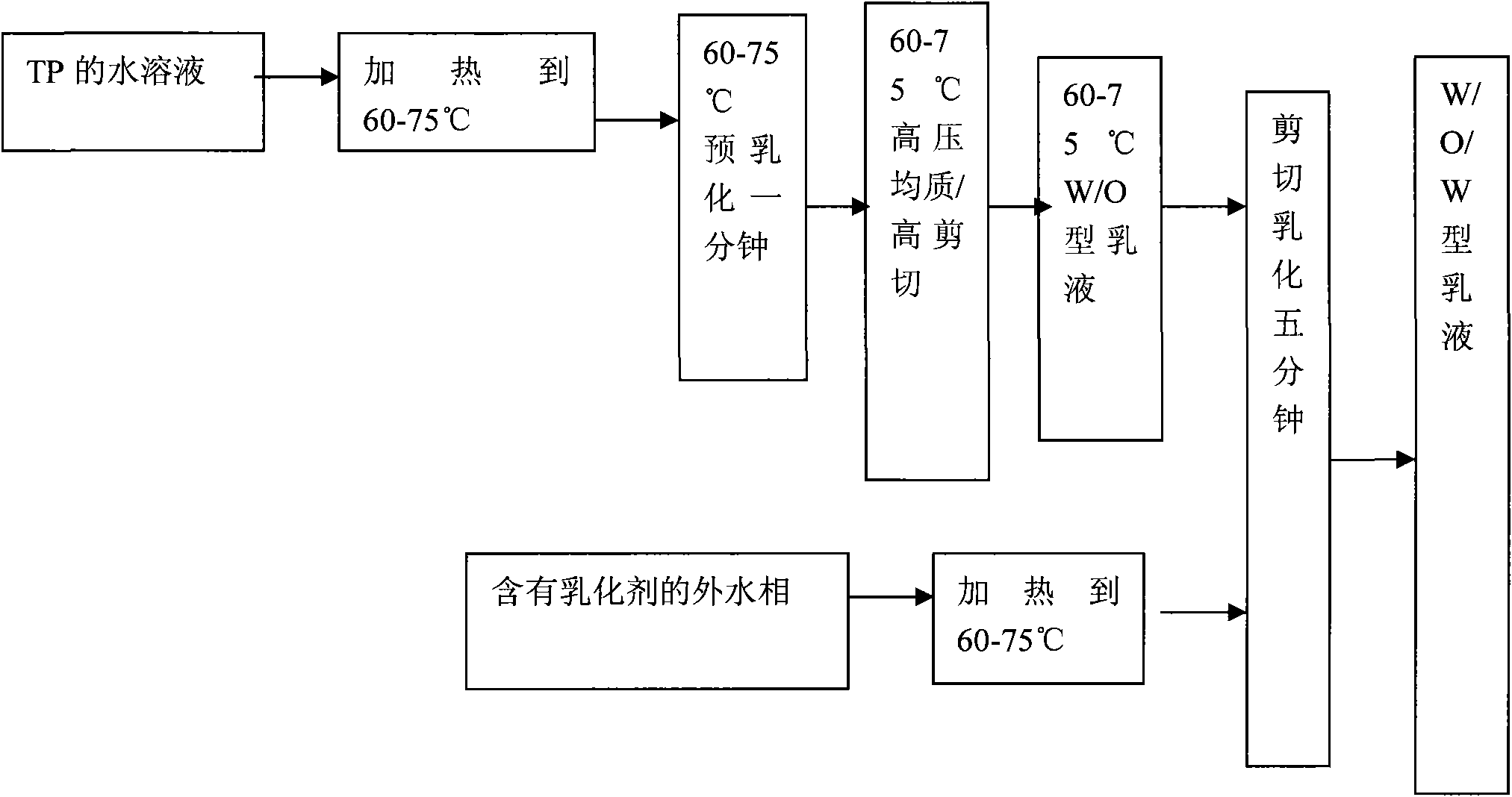

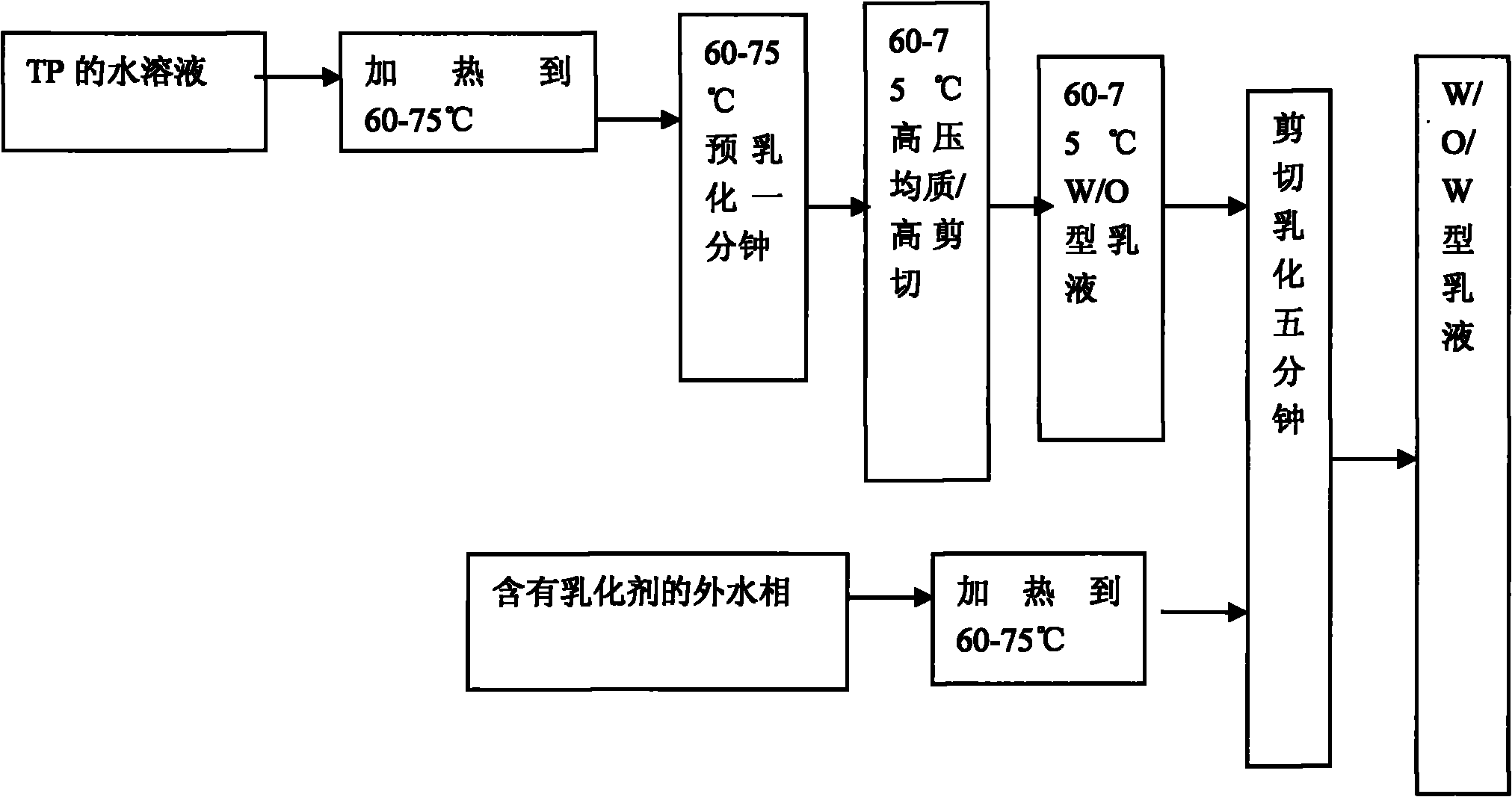

Multiple emulsion for loading tea polyphenol and preparation method thereof

ActiveCN101843571AThe preparation process conditions are easy to controlImprove stabilityCosmetic preparationsToilet preparationsEmulsionCentrifugation

The invention discloses a multiple emulsion for loading tea polyphenol and a preparation method thereof. The multiple emulsion comprises the following components by weight ratio: 0.5 -8 percent of tea polyphenol, 5 -15 percent of emulsifier, 10 -30 percent of lipid material and the balance of water. The emulsion has high stability, does not delaminate after being preserved for more than six months at normal temperature, does not delaminate under the condition of high-speed centrifugation at 4000r / min for 15min and can be applied to food, medicines and cosmetics.

Owner:PROYA COSMETICS

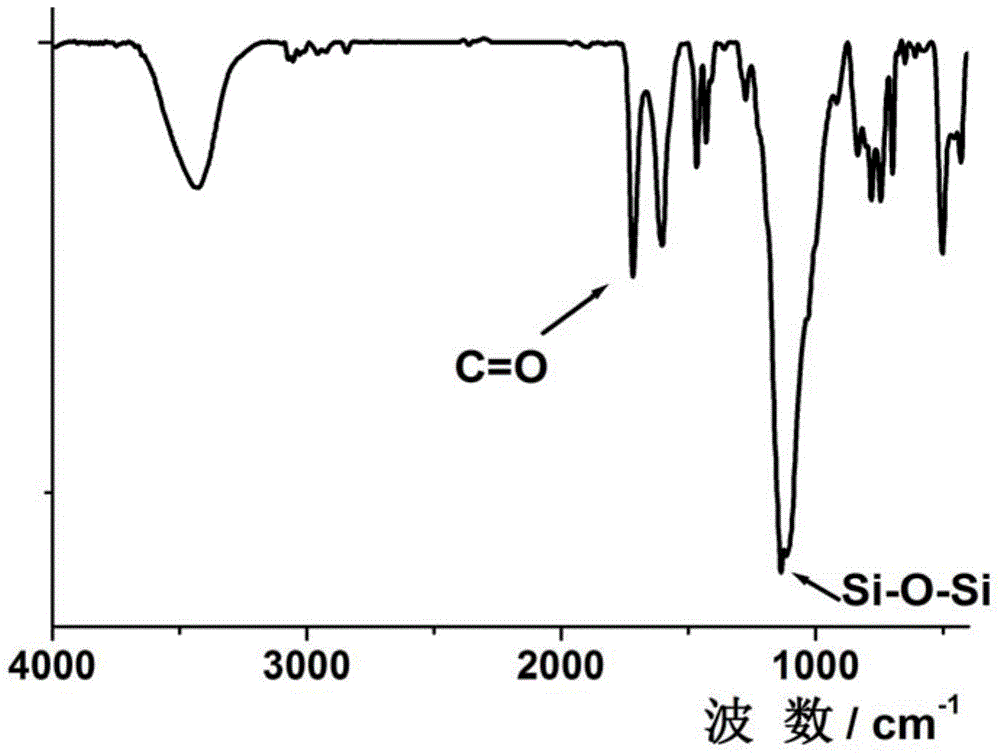

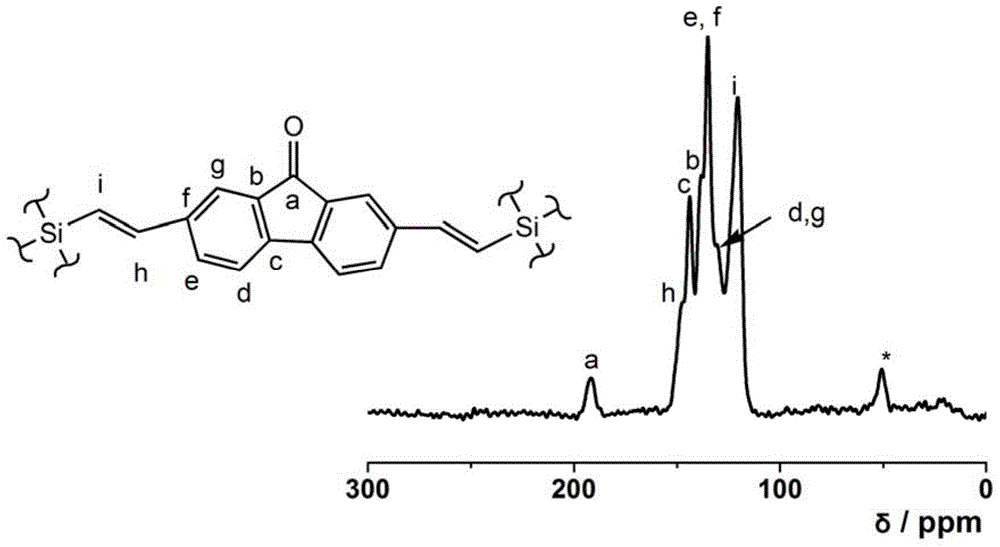

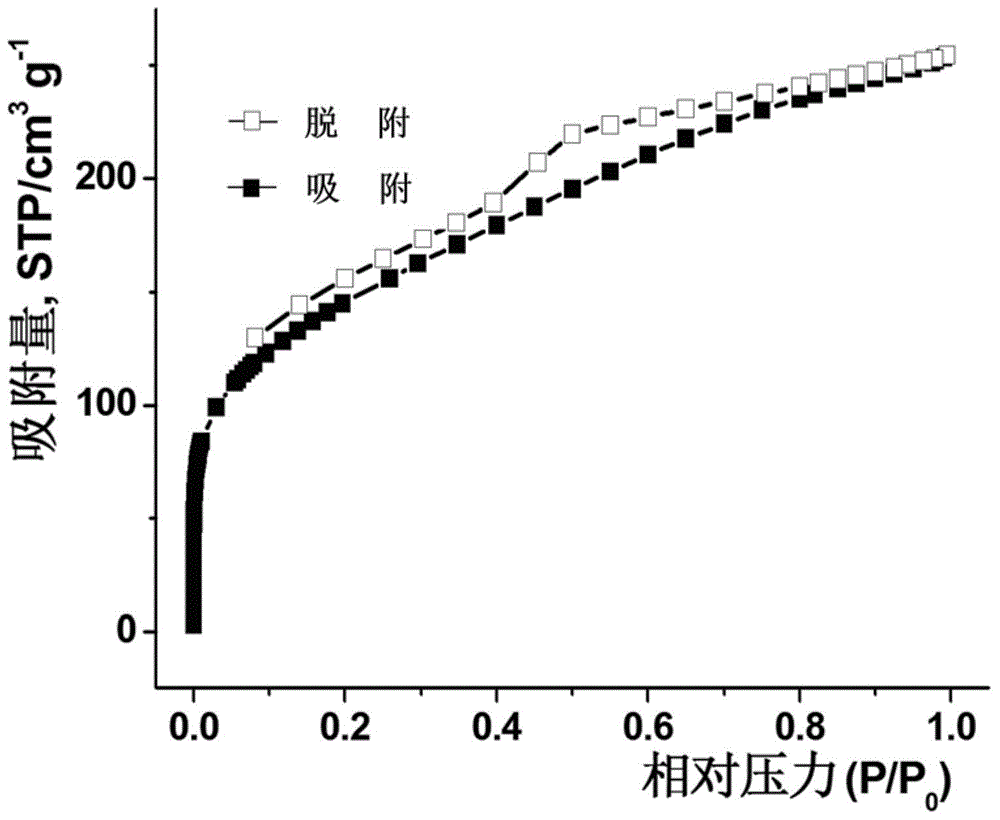

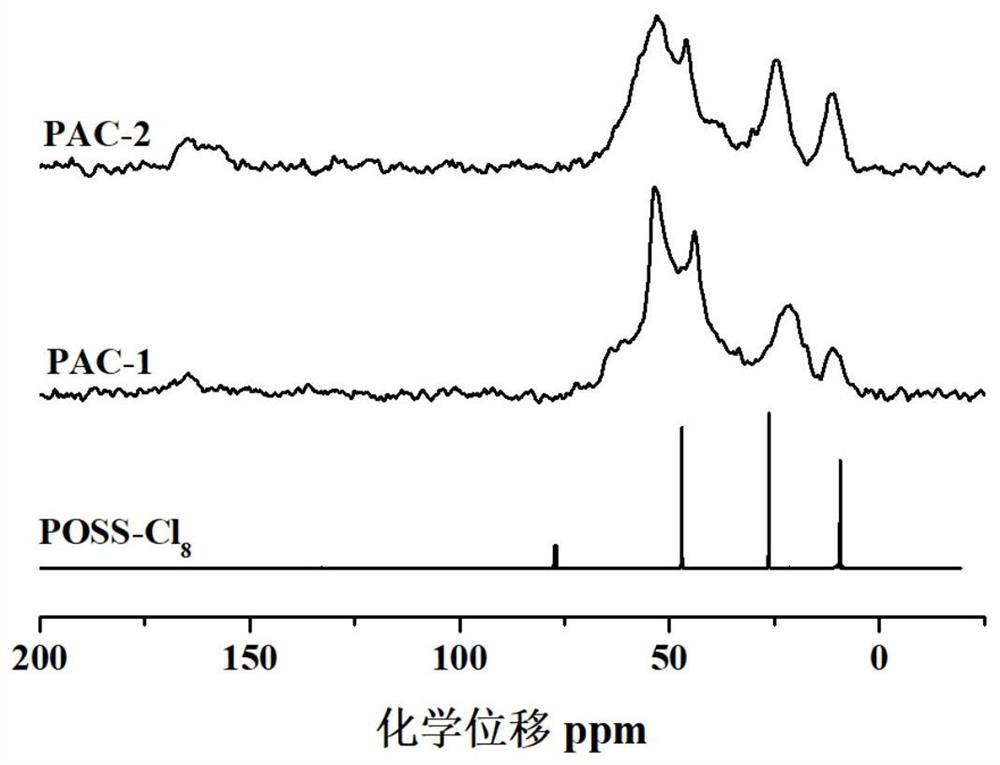

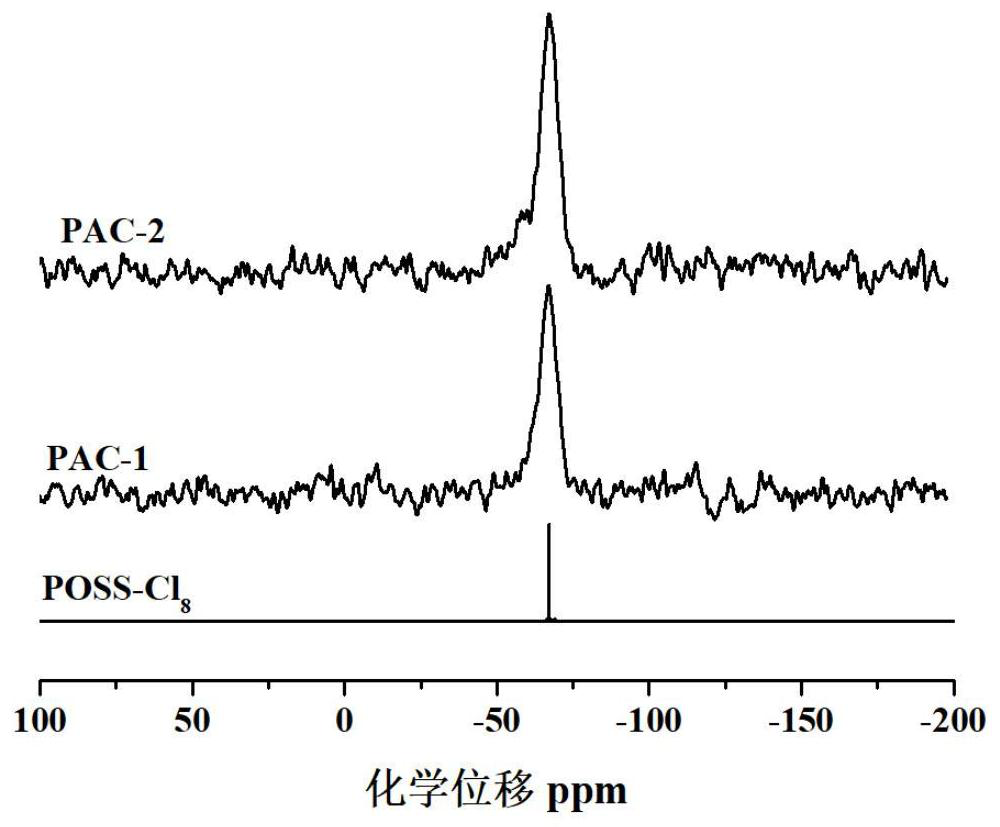

Preparation method of POSS (polyhedral oligomeric silsesquioxane)-based porous material capable of simultaneously improving porosity and carbon dioxide storage volume

ActiveCN104558016ALarge specific surface areaHigh pore volumeSilicon organic compoundsOther chemical processesPorosityOrganic acid

The invention relates to a preparation method of a POSS (polyhedral oligomeric silsesquioxane)-based porous material capable of simultaneously improving porosity and carbon dioxide storage volume. The preparation method comprises the following steps: (1) dispersing the POSS-based porous material in an organic solvent, adding a primary amine compound and an organic acid catalyst, and carrying out reflux reaction under a stirring condition for 12-48 hours, wherein the POSS-based porous material comprises a POSS unit and a fluorenone unit, and the primary amine compound at least comprises two amino groups; and (2) after reaction, filtering, washing the filter cake and drying in vacuum to obtain the material. Compared with a raw material POSS-based porous material, the POSS-based porous material prepared by the method has preferable porous performance and carbon dioxide storage performance, and the BET specific surface area, pore volume and carbon dioxide storage volume are improved to a certain extent.

Owner:SHANDONG UNIV

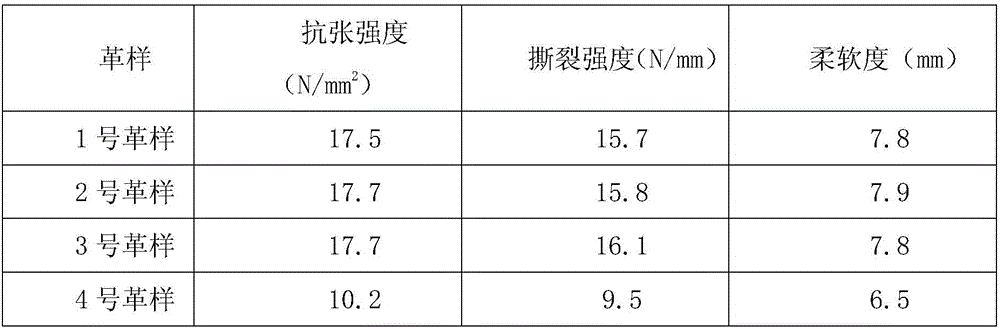

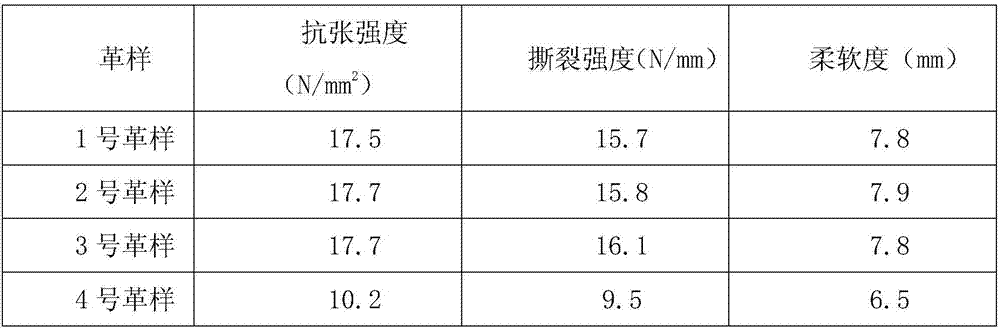

Preparation method for modified camellia oil fatting agent for leather processing

ActiveCN106191341AHigh tensile strengthHigh tear strengthLeather impregnationDistillationHydroxyl value

The invention relates to a preparation method for a modified camellia oil fatting agent for leather processing. The method comprises the following steps that a, 850-900 parts by mass of camellia oil, 74-148 parts by mass of n-butyl alcohol and 3-7 parts by mass of catalyzers are taken and added into a reactor; and b, reaction is carried out for 2-3 h at 100-120 DEG C, the hydroxyl value in a reaction system is measured, and by the total amount of reactants, when the hydroxyl value is greater than or equal to 65 mg KOH / g, butyl alcohol which is not fully reacted is removed through reduced pressure distillation.

Owner:JIAXING UNIV

Process for preparing alpha-calcium phosphate as basic material of bone reparing biological material

InactiveCN1338425AHigh purityGood biocompatibilityCoatingsPhosphorus compoundsCalcium biphosphateAlkaline earth metal

An alpha-calcium phosphate as the basic material of bone-repairing biologic material is prepared from calcium phosphate and calcium carbonate through proportional mixing, adding compound mineralizingagent, wet grinding, drying, sieving, high-temp calcining, and naturally cooling. Said mineralizing agent is the fluoric alkali-earth metal salts or alkali metal salts (potassium fluoride or calcium fluoride). Its advantages include high purity and better biologic compatibility and mechanical performance.

Owner:TIANJIN UNIV

A hybrid gel of polylactic acid microspheres and cross-linked hyaluronic acid for injection and its preparation method

The invention relates to a mixed gel of polylactic acid microspheres and cross-linked hyaluronic acid for injection and a preparation method of the mixed gel. The polylactic acid microspheres have the molecular weight of 15000-120000 and the average particle size of 10-150mu m, and the mass fraction of the polylactic acid microspheres in the mixed gel is 5-25%; a salt solution of the cross-linked hyaluronic acid gel is obtained by swelling and balancing the cross-linked hyaluronic acid gel in a sodium chloride solution or a phosphate buffer solution with the osmotic pressure of 250-350mOsmol / L and the pH value of 6.5-7.5; the cross-linked hyaluronic acid gel is a hyaluronic acid gel cross-linked by divinyl sulfone or glycidyl ether. A mixed gel product of polylactic acid and cross-linked hyaluronic acid, obtained by directly mixing the polylactic acid microspheres with the cross-linked hyaluronic acid gel obtained by swelling and balancing in the salt solution is uniform, fine, long in partial retention time, good in plasticity and few in side effects, has an obvious effect on eliminating wrinkles, and has few operation steps and stable product quality.

Owner:河北善远科技有限公司

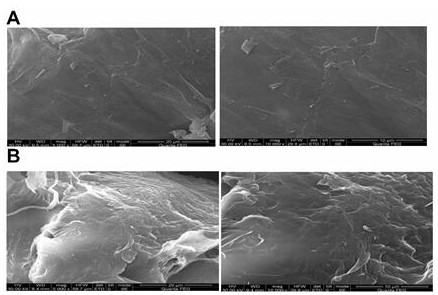

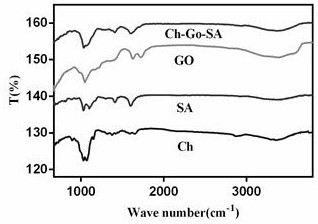

Clarifying agent for fruit wine and preparation method of clarifying agent

ActiveCN110624515AIncrease contact areaLarge adsorption capacityOther chemical processesAlcoholic beverage preparationIonSolvent

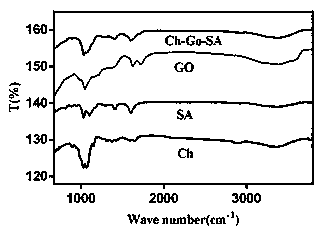

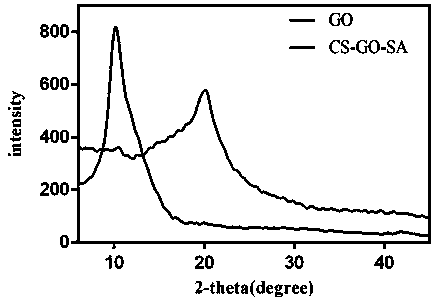

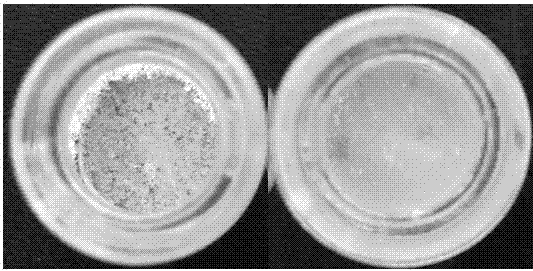

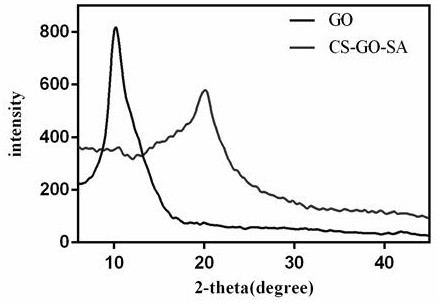

The invention discloses a clarifying agent for fruit wine and a preparation method of the clarifying agent. The clarifying agent for the fruit wine is prepared from the following components: 0.01 g to0.05 g of graphene oxide, 0.4 g to 0.6 g of chitosan, 0.4 g to 0.6 g of sodium alginate, 0.3 mL to 0.6 mL of an acetic acid solution, 0.5 mL to 1.0 mL of glutaraldehyde and 50 mL of ultrapure water which is used as a solvent. The composite structure formed by using the chitosan, the graphene oxide and the sodium alginate has a better adsorption effect on substances which easily generate compositeprecipitates in the fruit wine, so that a wine body has a high clarifying degree and gloss; the clarifying agent effectively adsorbs substances such as protein and metal ions in the fruit wine, has agood clarification effect, and avoid turbidity; and meanwhile, the clarifying agent can effectively improve stability of the fruit wine, so that the fruit wine cannot be turbid during long-time storage, and the shelf life of the fruit wine is prolonged.

Owner:LUZHOU LAOJIAO +1

Hyaluronic acid mixed gel containing amphiphilic microspheres for injection and preparation method thereof

ActiveCN105126166BIrritant effectDifficult to assembleOrganic active ingredientsProsthesisPhosphateMicrosphere

The invention relates to a hyaluronic acid mixed gel containing amphiphilic microspheres for injection and a preparation method thereof. The microsphere material involves amphiphilic materials such as PLLA-PEG, PLGA, and PLGA-PEG. The molecular weight of PLLA or PLGA is 10,000-500,000, and that of PEG is 1,000-10,000. In PLGA, LA / GA=90 / 10-10 / 90. The average particle size of the microspheres is 1-200 μm, and the mass fraction in the gel is 1-50%; the gel component is hyaluronic acid, or hyaluronic acid cross-linked with divinyl sulfone or glycidyl ether, The molecular weight of hyaluronic acid is 100,000-3,000,000, and the mass fraction is 1-50%. The gel component can also be animal-derived collagen, chitosan, amino acid cellulose, sodium alginate, and the like. The microsphere mixed gel is prepared in a sodium chloride solution or a phosphate buffer solution with an osmotic pressure of 250-350 mOsm / L and a pH of 6.5-7.5. In the present invention, the amphiphilic microspheres are directly mixed with the hyaluronic acid gel, and the amphiphilic microspheres are easily and uniformly distributed in the gel, and after being injected into the human body, they are not easy to assemble into lumps in the water environment of the human body.

Owner:IMEIK TECH DEV CO LTD

Preparation method for small-diameter artificial silk fibroin blood vessel with high unblocked rate

InactiveCN104922728AImprove adhesionGood biocompatibilityProsthesisBiocompatibility TestingAnimal body

The invention discloses a preparation method for a small-diameter artificial silk fibroin blood vessel with high unblocked rate, and belongs to the field of biomedical materials. The small-diameter artificial silk fibroin blood vessel is obtained by uniformly coating a specific metal mould with an anticoagulant modified silk fibroin solution, performing rotary forming and heat drying, and soaking in an ethanol aqueous solution. Silk fibroin blood vessels different in performance and shape can be prepared as needed; the mechanical performance of the blood vessel is controlled by regulating the rotational speed and the drying temperature of the mould; the thickness of the blood vessel is controlled by the number of coating layers; the diameter of the blood vessel is controlled by regulating the diameter of the mould. The silk fibroin blood vessel obtained by the preparation method has good biocompatibility, blood compatibility and mechanical performance; the diameter of the silk fibroin blood vessel is smaller than 6 mm, the silk fibroin blood vessel is formed once, and the preparation process is simple; the silk fibroin blood vessel is good in adaptability and free of obvious stress defects, keeps unblocked in an animal body within 6 months, and lays a certain foundation for clinical application of small-diameter blood vessels.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Aluminum member surface microetching method, aluminum member complex and preparation method thereof

The invention provides an aluminum member surface microetching method, an aluminum member complex and a preparation method thereof. The aluminum member surface microetching method comprises the following steps: performing pretreatment of oil removing, neutralizing treatment and alkali corrosion treatment in order on an aluminum member, microetching on the pre-treated surface of the aluminum member, forming micropore on the surface of the aluminum member; performing micropore washing treatment and pore enlarging treatment on the micropore formed on the surface of the aluminum member. The aluminum member complex comprises the aluminium member and a bonding member combined with the aluminum member, the aluminum member is processed by an aluminum member surface microetching method, the surface etched with the micropore is coated by a binder, and the aluminum member is bound with a plastic member or a resin piece. The aluminum member surface microetching method can generate various micropores on the surface of the aluminum member, and can effectively enhance the bonding strength between the aluminum member and other materials or the members such as resin or plastics.

Owner:OPD TECH SHENZHEN

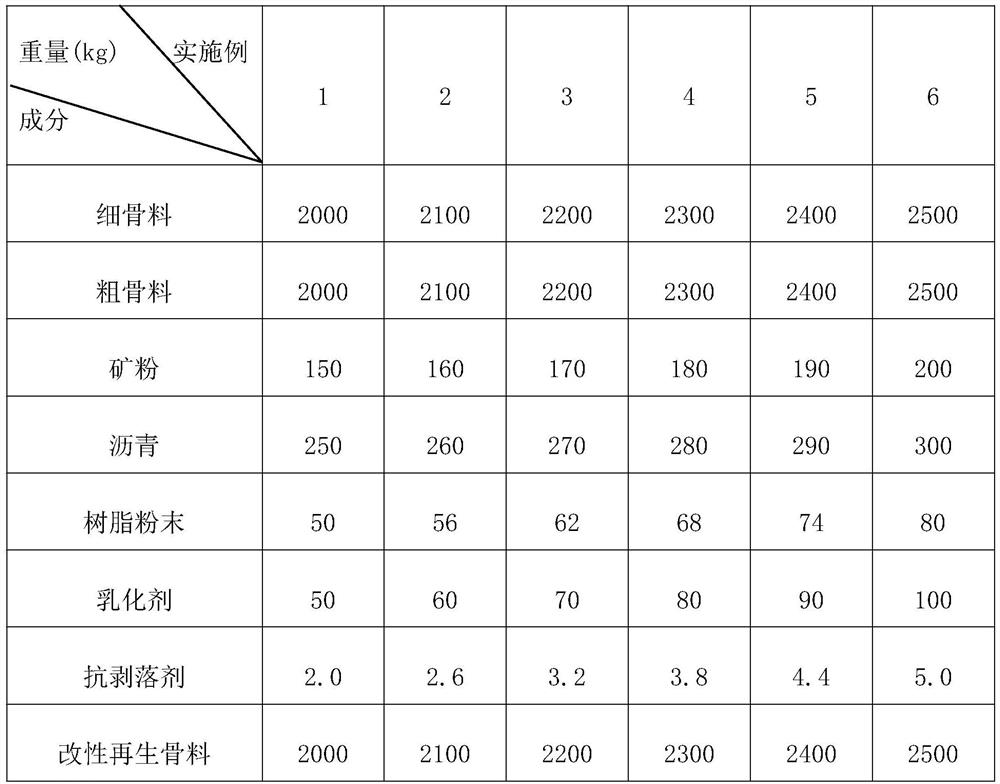

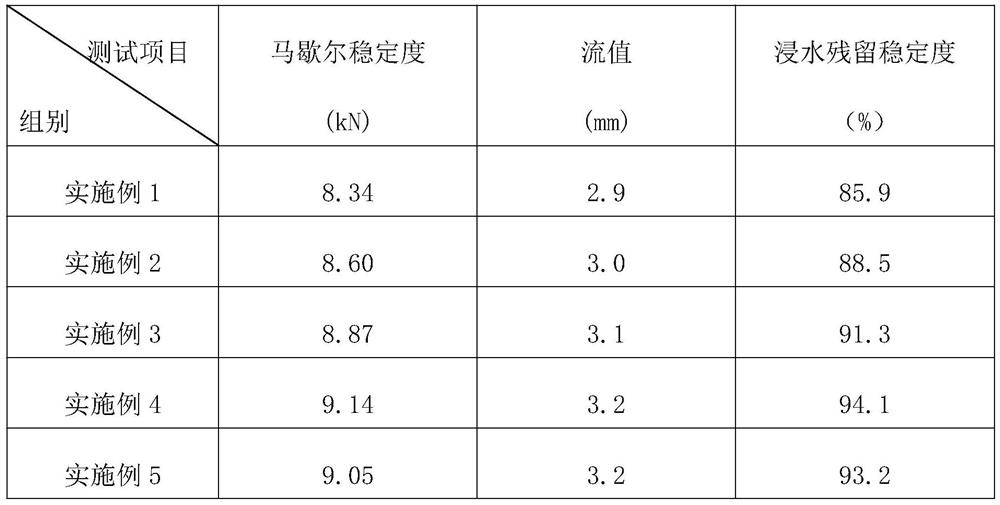

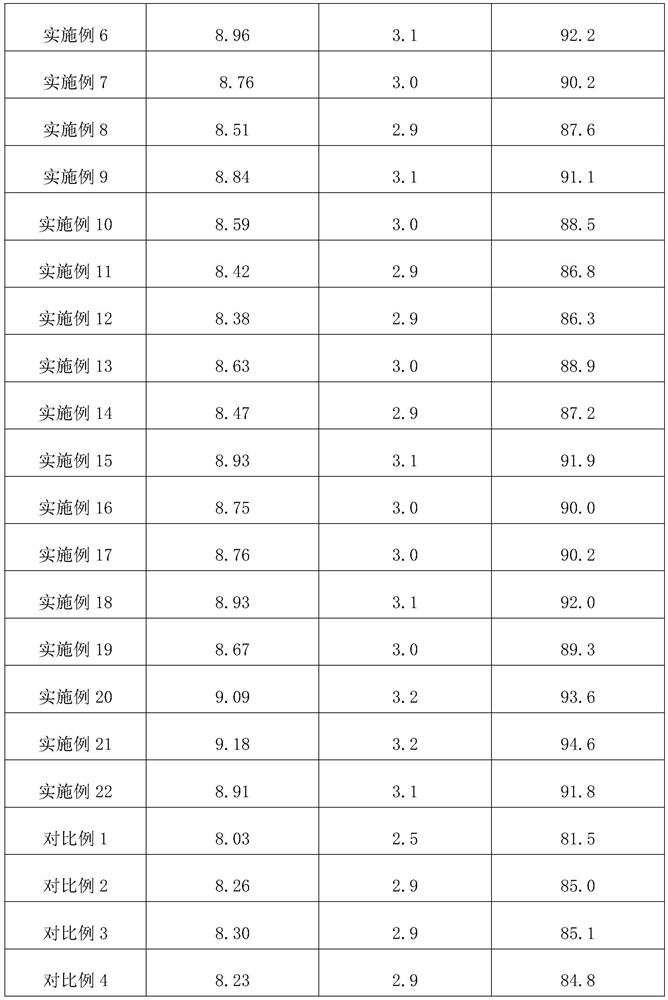

Environment-friendly asphalt mixture and preparation method thereof

InactiveCN113307547ANot easily affected by acidity and alkalinityGuaranteed Marshall StabilityEnvironmental engineeringAsphalt

The invention relates to the technical field of preparation of asphalt mixtures, and particularly discloses an environment-friendly asphalt mixture and a preparation method thereof. The environment-friendly asphalt mixture is prepared from the following components in parts by weight: 2000 to 2500 parts of fine aggregate, 2000 to 2500 parts of coarse aggregate, 150 to 200 parts of mineral powder, 250 to 300 parts of asphalt, 50 to 80 parts of resin powder, 50 to 100 parts of an emulsifier, 0.6 to 1.2 parts of an anti-stripping agent, and 2000 to 2500 parts of modified recycled aggregate, wherein the modified recycled aggregate is prepared from waste concrete blocks through crushing, acid pickling, alkalization, modification, calcination and other procedures. According to the environment-friendly asphalt mixture disclosed by the invention, the waste concrete blocks are recycled, and multiple modification procedures are matched for treatment, so the environment-friendly asphalt mixture has the advantages of environmental protection, energy conservation, and high Marshall stability and immersion residue stability at the same time.

Owner:上海繁荣道路建设工程有限公司

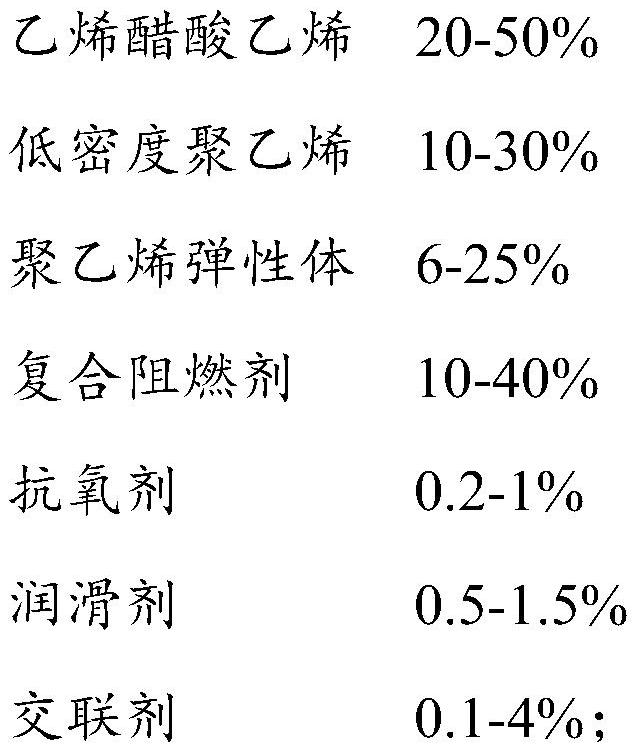

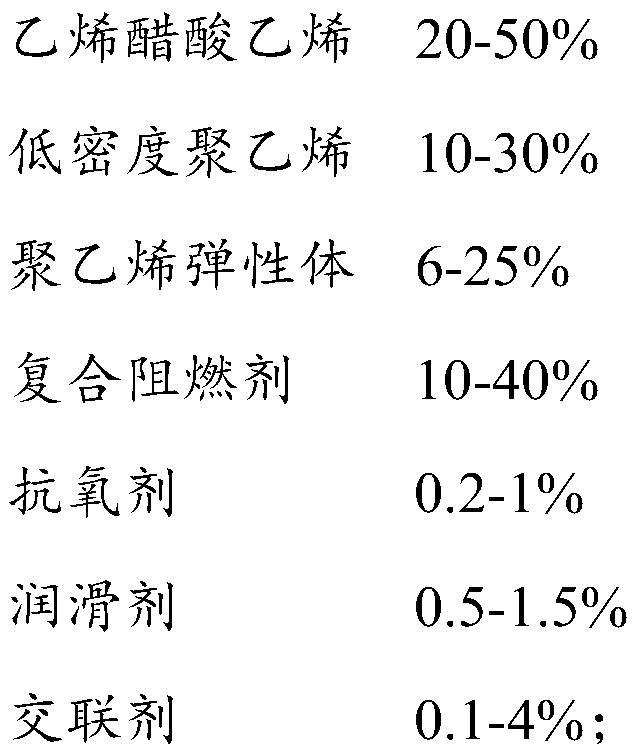

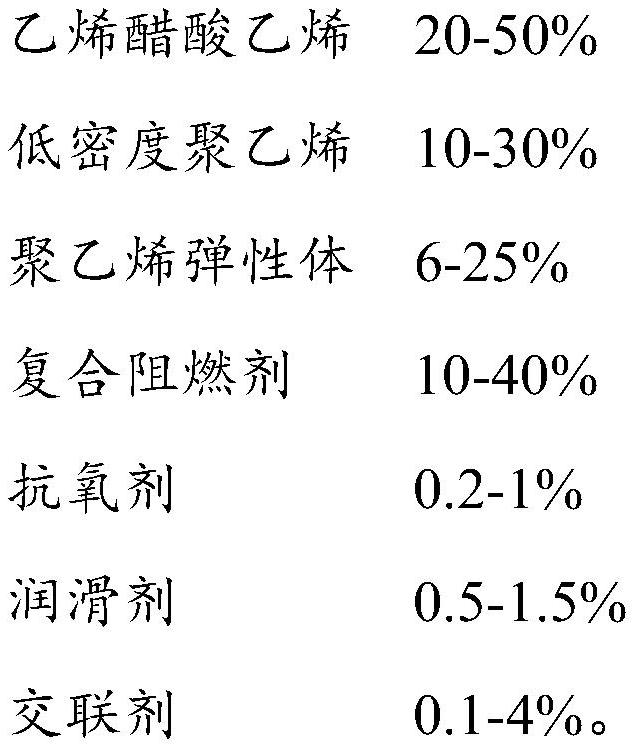

Flame-retardant polyolefin composite material as well as preparation method and application thereof

ActiveCN113527800AImprove flame retardant performanceStable mechanical propertiesElastomerPolyolefin

The invention discloses a flame-retardant polyolefin composite material as well as a preparation method and application thereof. The flame-retardant polyolefin composite material comprises the following formula components: 20-50% of ethylene vinyl acetate, 10-30% of low-density polyethylene, 6-25% of polyethylene elastomer, 10-40% of a composite flame retardant, 0.2-1% of an antioxidant, 0.5-1.5% of a lubricant and 0.1-4% of a cross-linking agent, wherein the composite flame retardant comprises a mixture of magnesium hydroxide, calcium carbonate and frit. A resin matrix of the flame-retardant polyolefin composite material can form a three-dimensional network connection structure, and the flame-retardant polyolefin composite material is endowed with excellent impact resistance, elasticity, tear resistance and other mechanical properties and high temperature resistance. The composite flame retardant containing the mixture of the magnesium hydroxide, calcium carbonate and frit endows the polyolefin composite material with excellent flame retardant property, does not generate toxic components during combustion, and is safe and environment-friendly.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

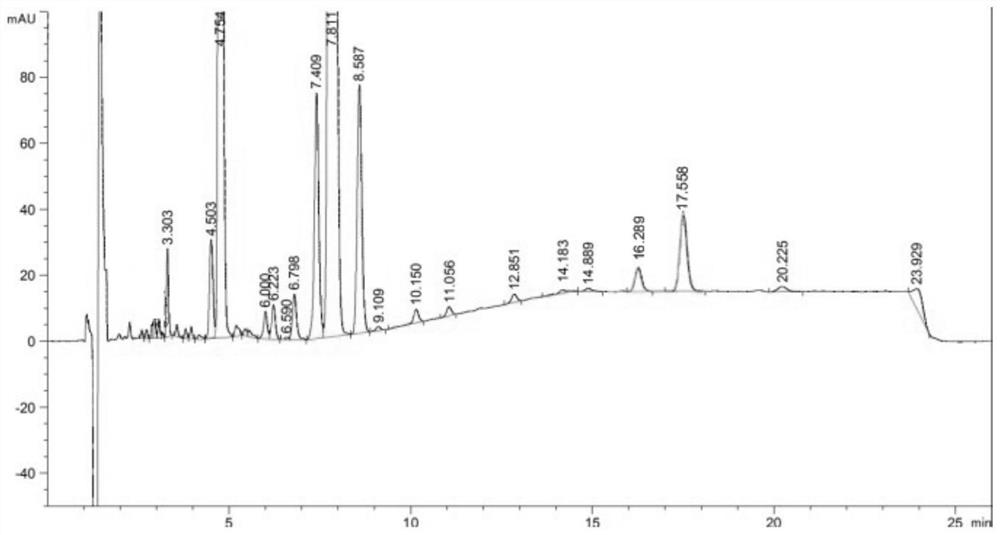

Method for preparing cannabidiol

PendingCN114057551AHigh extraction rateLess impuritiesOrganic chemistryOrganic compound preparationAlcoholSorbent

The invention discloses a method for preparing secondary cannabidiol, which at least comprises the following steps: a) pretreating a raw material containing industrial hemp to obtain a pretreated material; b) performing alcohol extraction on the pretreated material, concentrating an extracting solution I to obtain a concentrated solution, adding water for decarboxylation, and concentrating II to obtain a dry extract; c) mixing the dry extract and an adsorbent I to form a solid dispersion system, and performing solid-phase extraction to obtain a secondary cannabidiol primary product solution; d) subjecting the crude cannabidiol solution to concentration III, decoloration and crystallization so as to obtain the secondary cannabidiol. The preparation method is simple in process, high in product transfer rate, time-saving, labor-saving, large in treatment capacity, high in product purity and suitable for industrial large-scale production.

Owner:YUNNAN HEMPMON PHARMA CO LTD

Process for preparing alpha-calcium phosphate as basic material of bone reparing biological material

InactiveCN1137044CHigh purityGood biocompatibilityCoatingsPhosphorus compoundsCalcium biphosphateAlkaline earth metal

An alpha-calcium phosphate as the basic material of bone-repairing biologic material is prepared from calcium phosphate and calcium carbonate through proportional mixing, adding compound mineralizing agent, wet grinding, drying, sieving, high-temp calcining, and naturally cooling. Said mineralizing agent is the fluoric alkali-earth metal salts or alkali metal salts (potassium fluoride or calcium fluoride). Its advantages include high purity and better biologic compatibility and mechanical performance.

Owner:TIANJIN UNIV

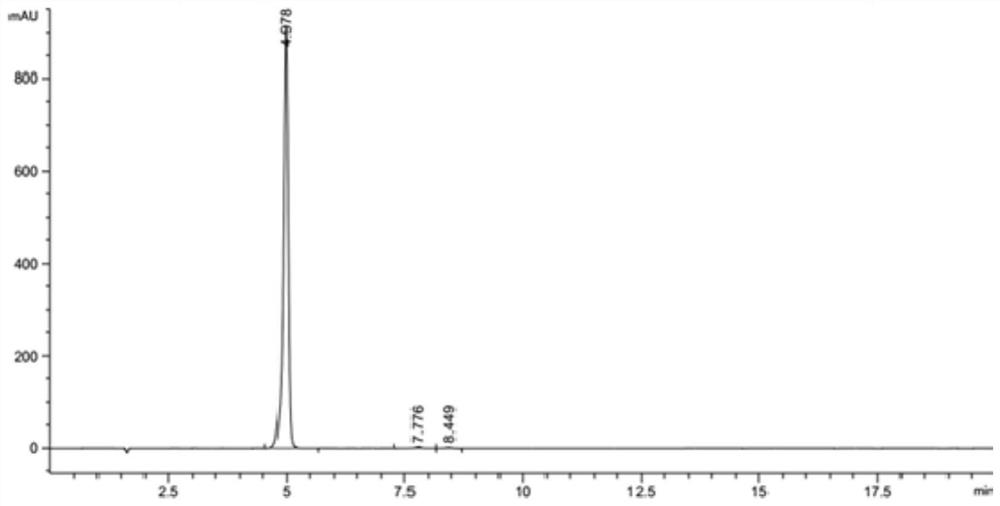

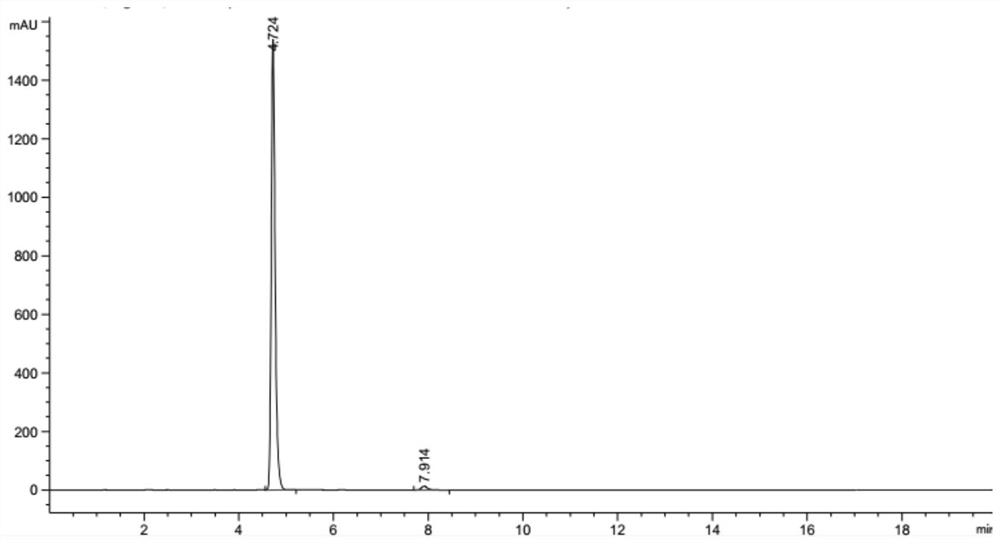

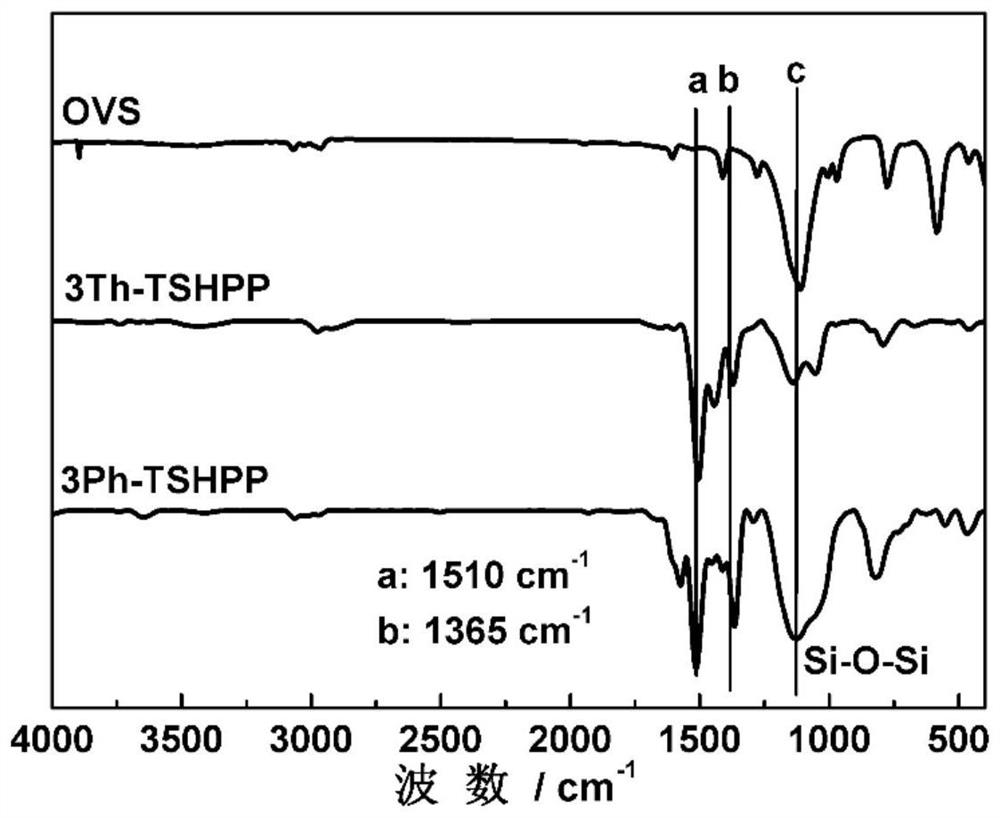

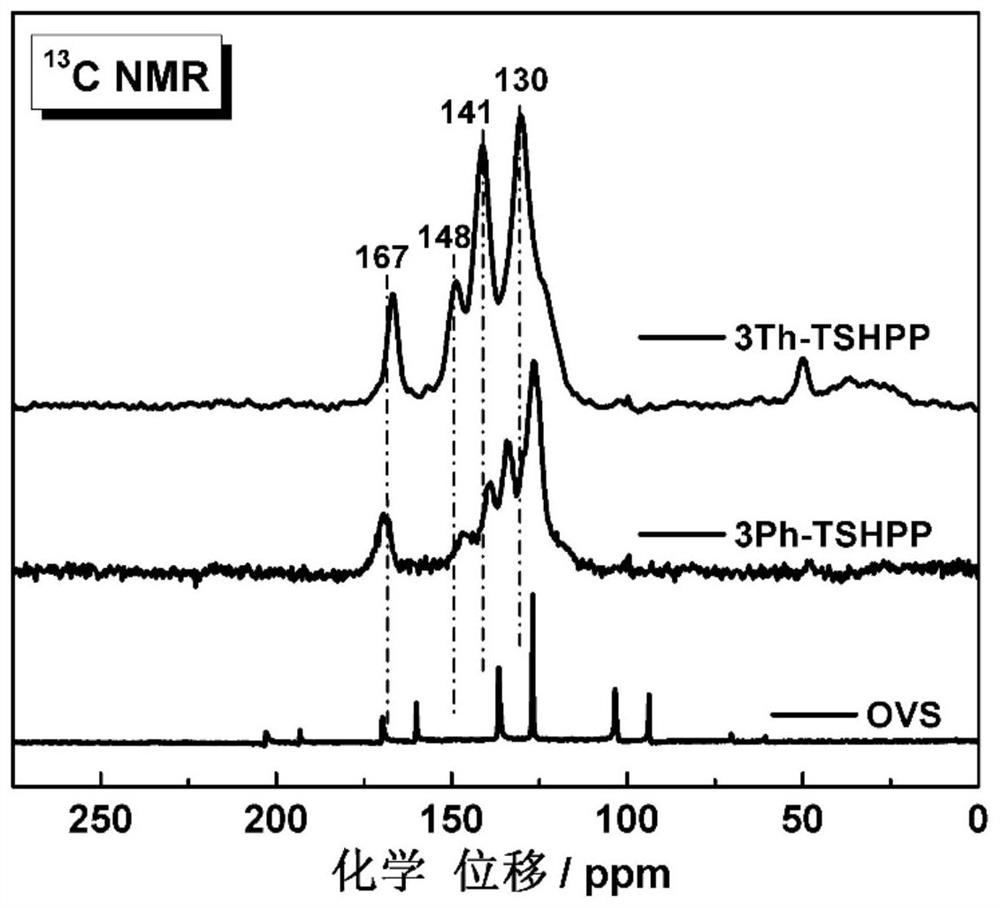

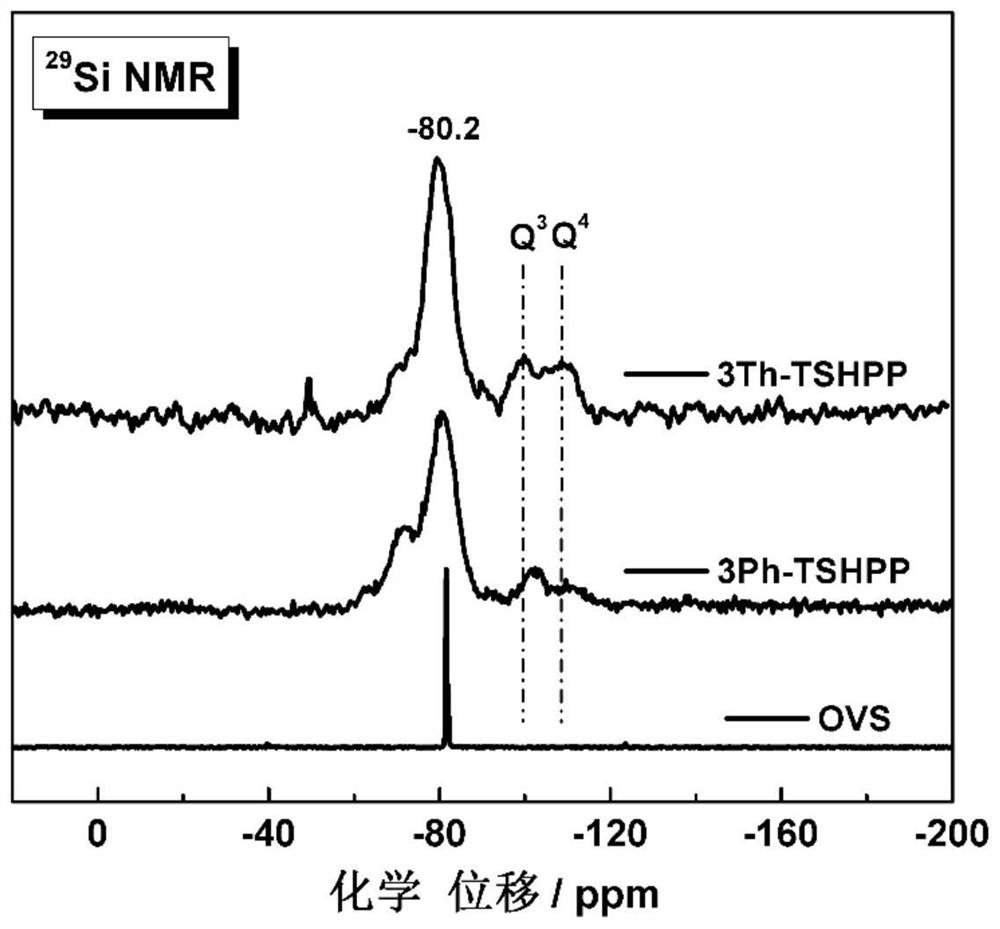

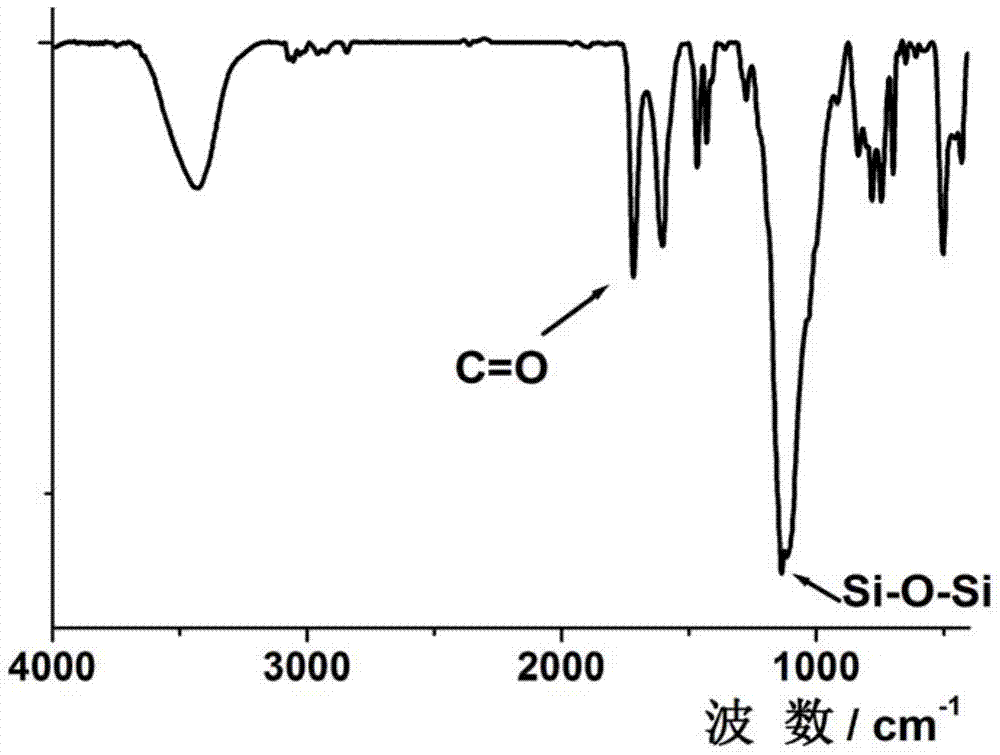

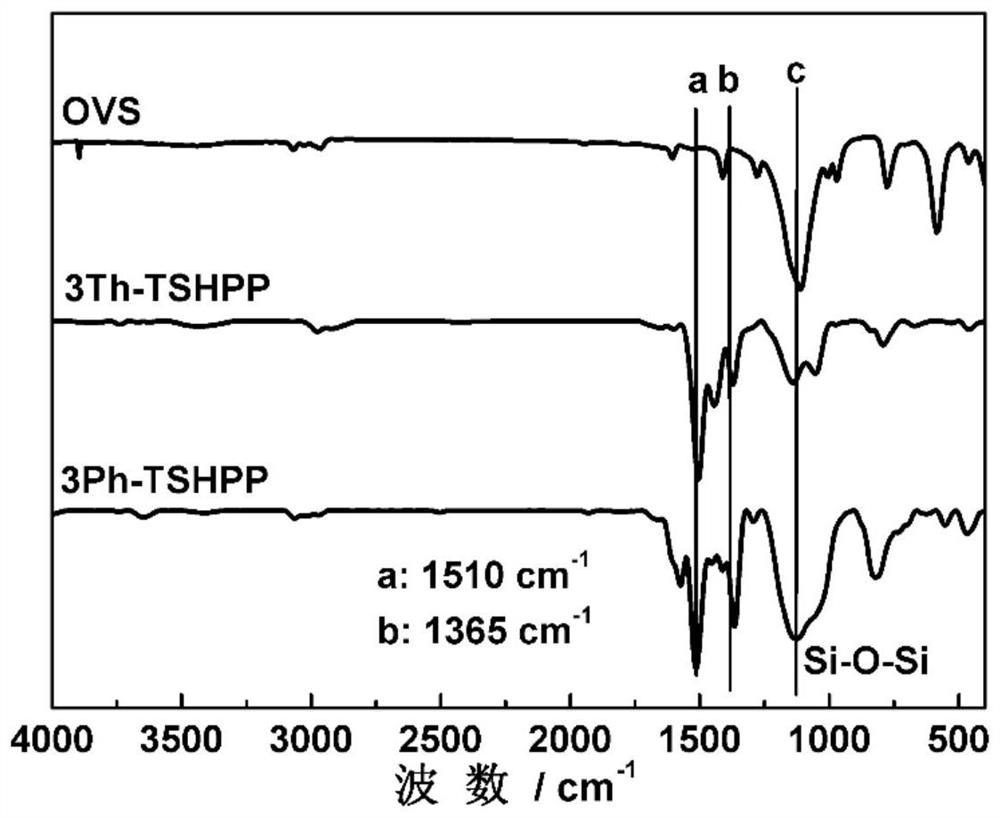

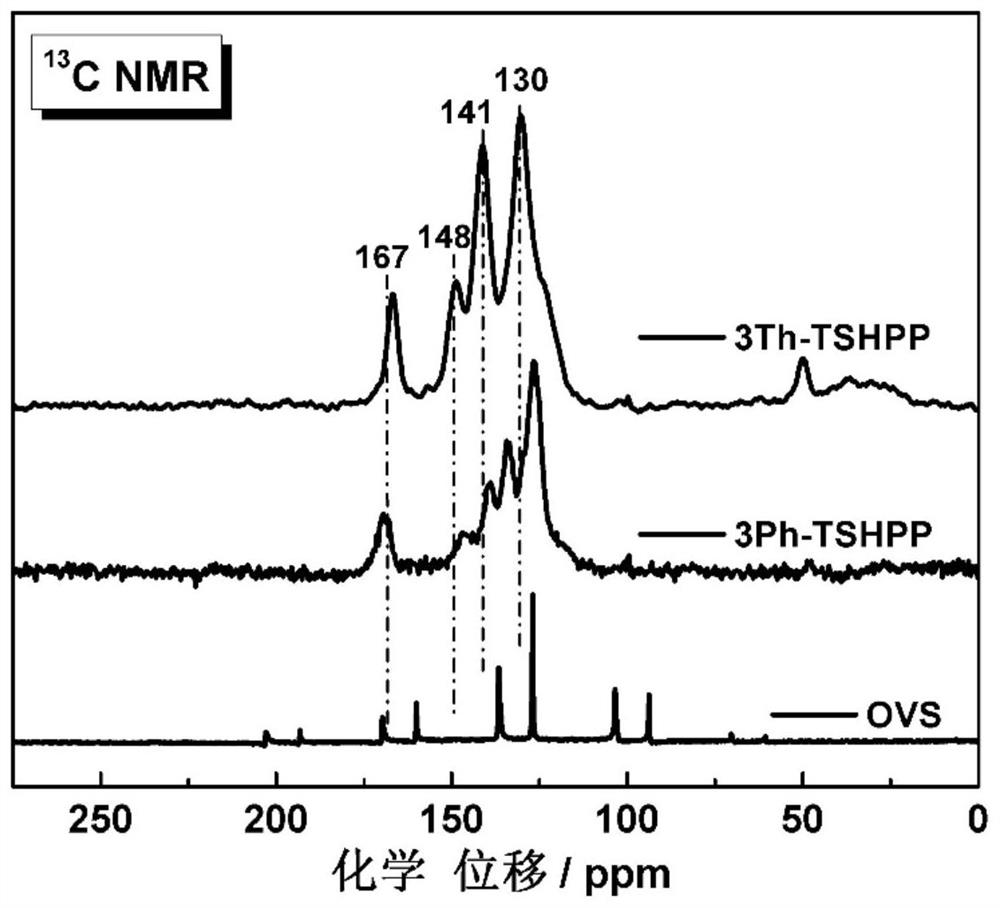

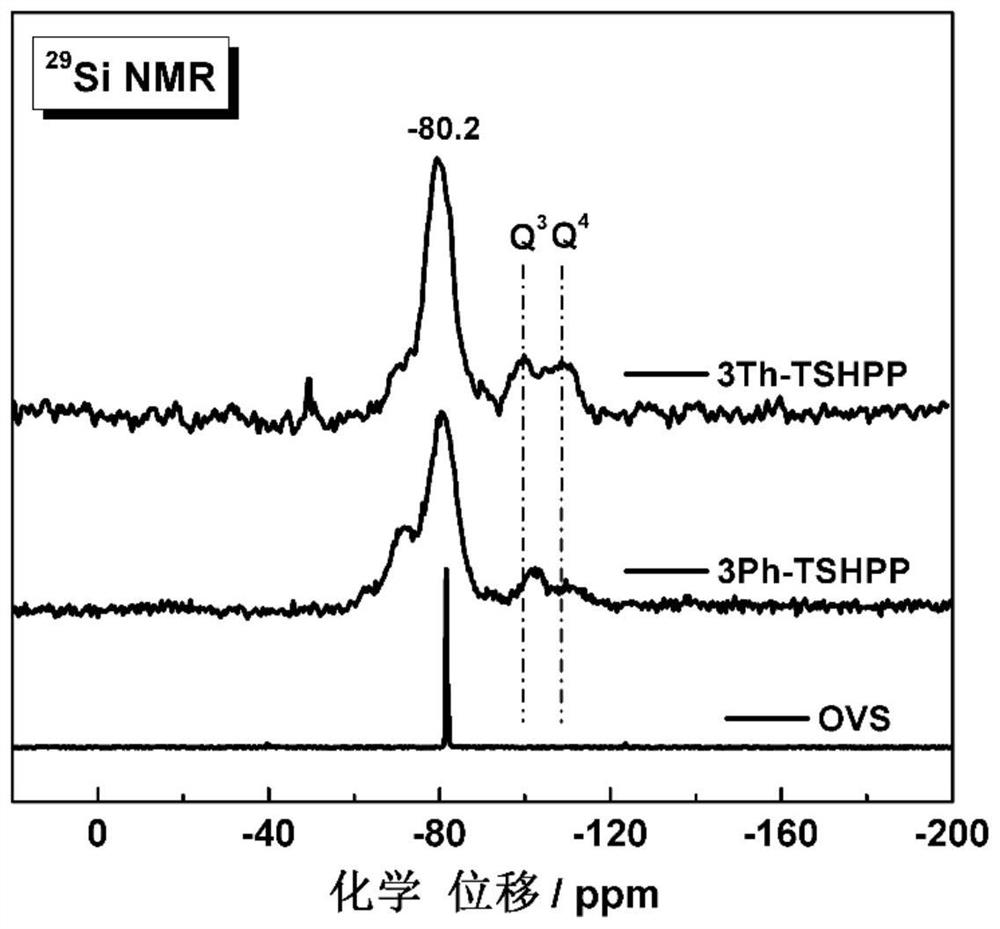

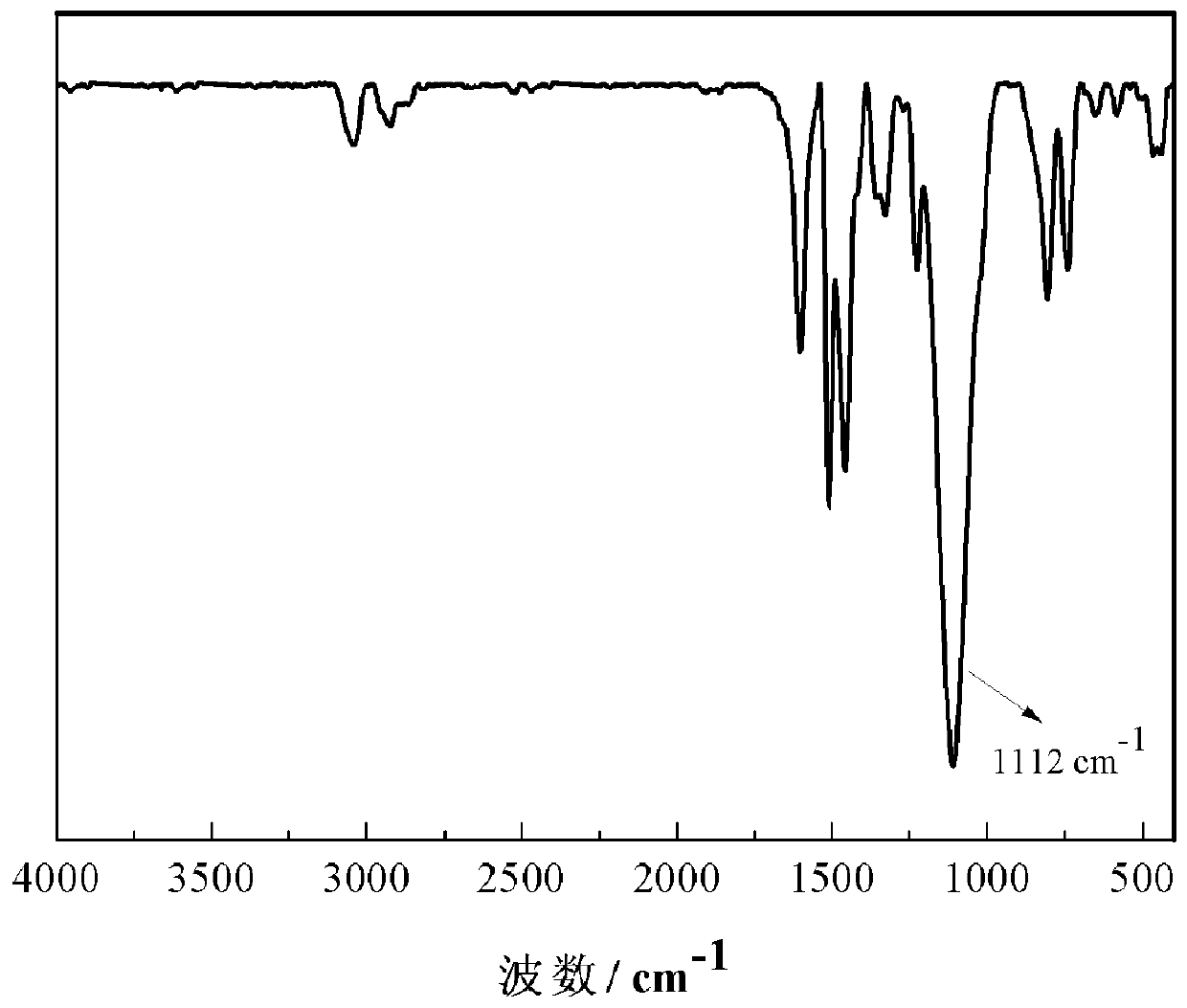

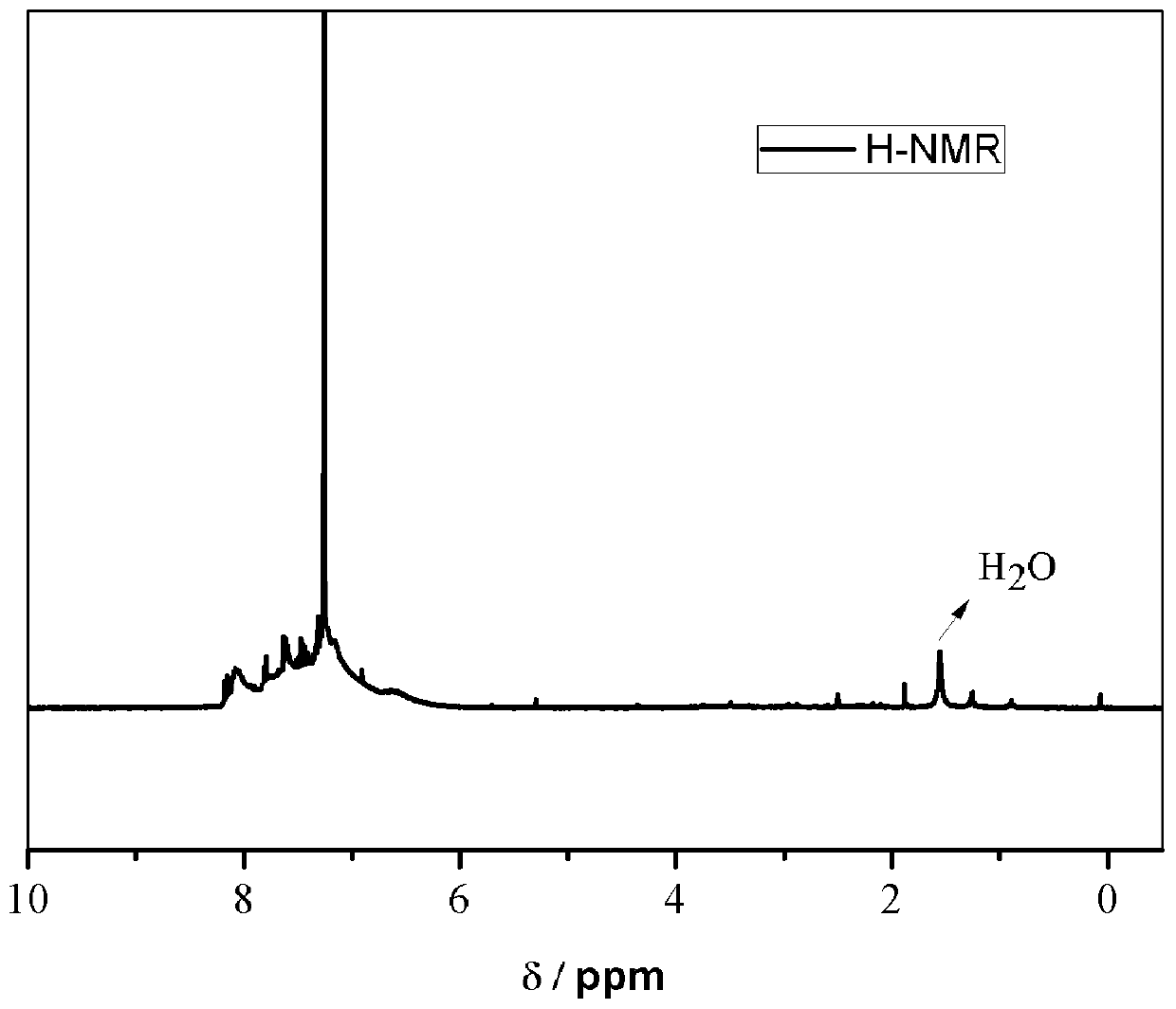

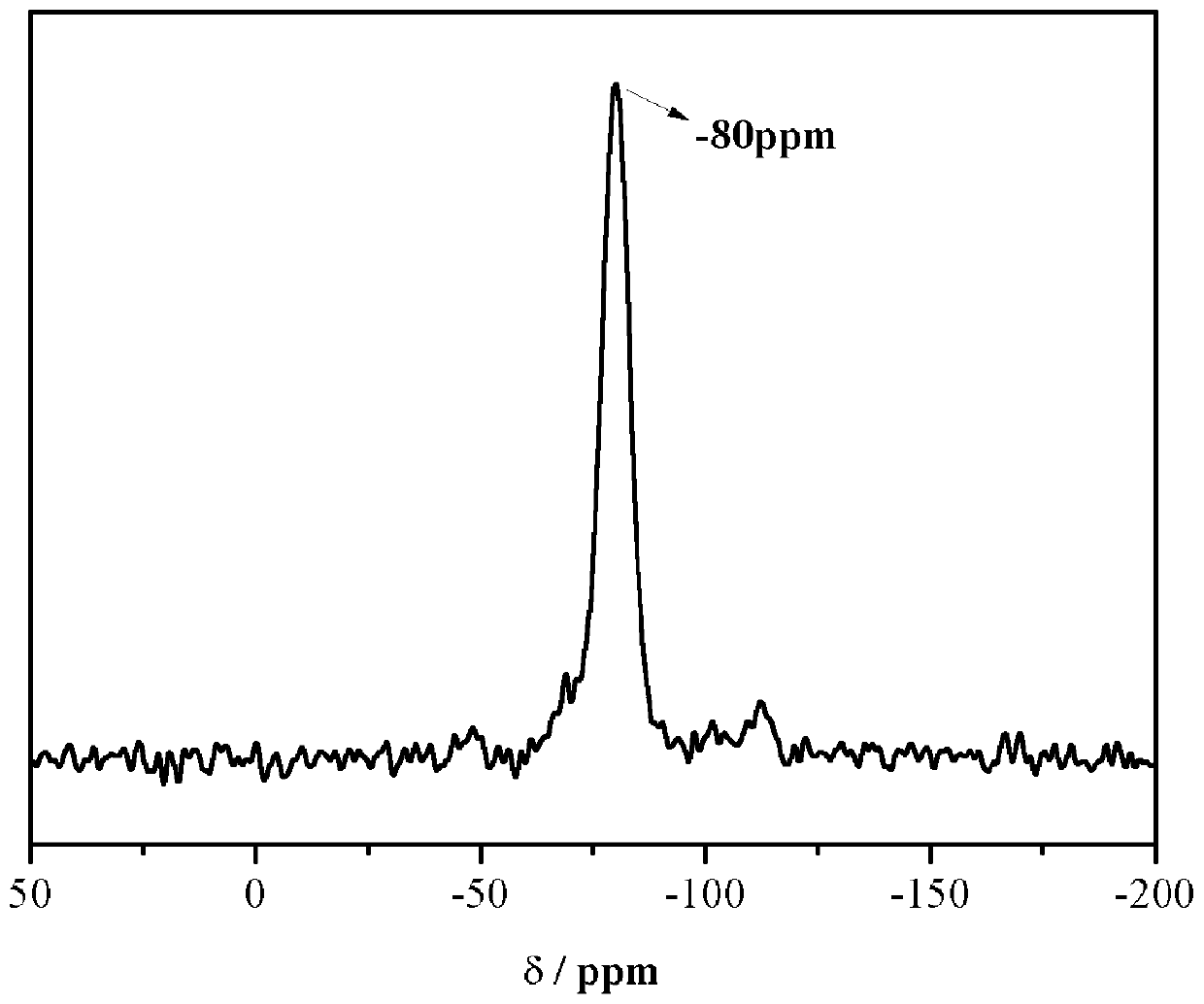

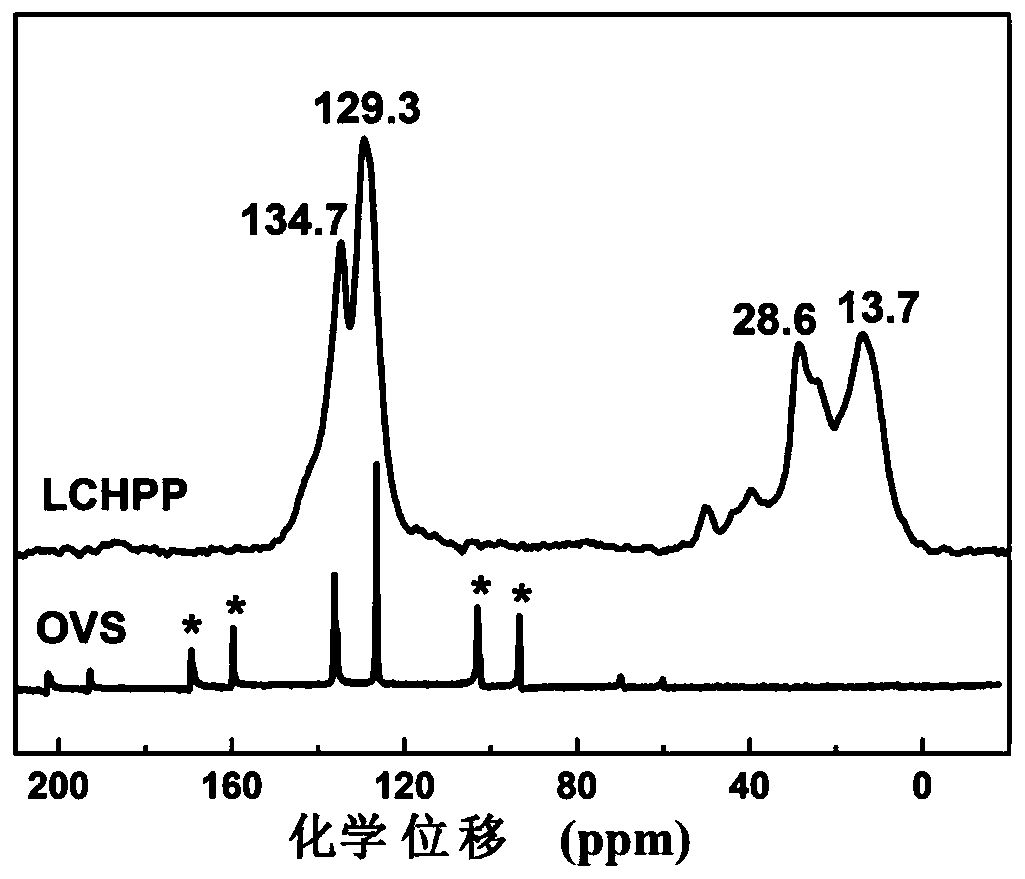

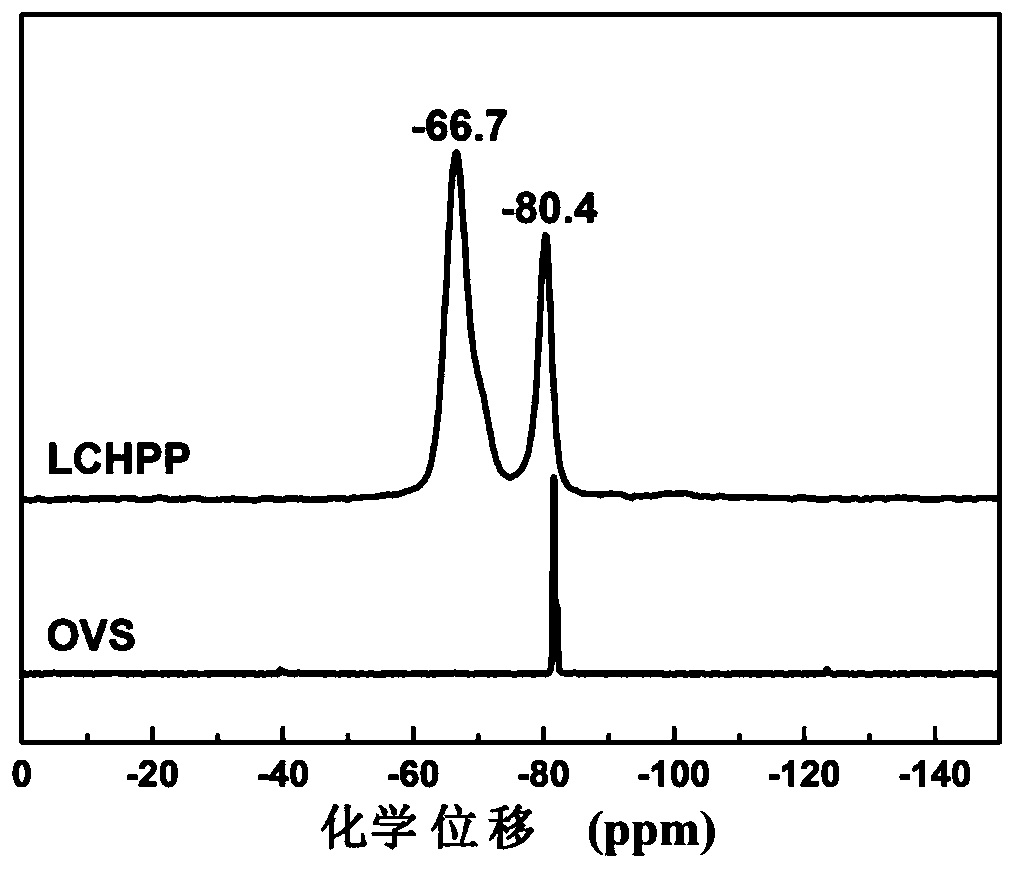

Triazine functionalized silsesquioxane-based hybrid porous polymer, preparation method and application thereof

ActiveCN112851944ASimple preparation stepsThe preparation process conditions are easy to controlWater/sewage treatment by irradiationWater treatment compoundsTriazineSilsesquioxane

The invention provides a triazine functionalized silsesquioxane-based hybrid porous polymer, a preparation method thereof and application thereof in catalytic degradation of dye pollutants. Octavinylsesquioxane (OVS) and a bromophenyl or thiophene substituted triazine monomer (TAs) are used as raw materials, and a Heck reaction is carried out to prepare the hybrid porous material with photocatalytic performance; the preparation method is simple, and reaction conditions are easy to realize; the obtained material has good chemical stability, thermal stability and fluorescence characteristics, the specific surface area and pore volume of the silsesquioxane-based hybrid porous material are greatly increased, and the silsesquioxane-based hybrid porous material shows efficient catalytic degradation capacity on dyes in wastewater and has huge potential application value in the field of sewage treatment.

Owner:SHANDONG UNIV

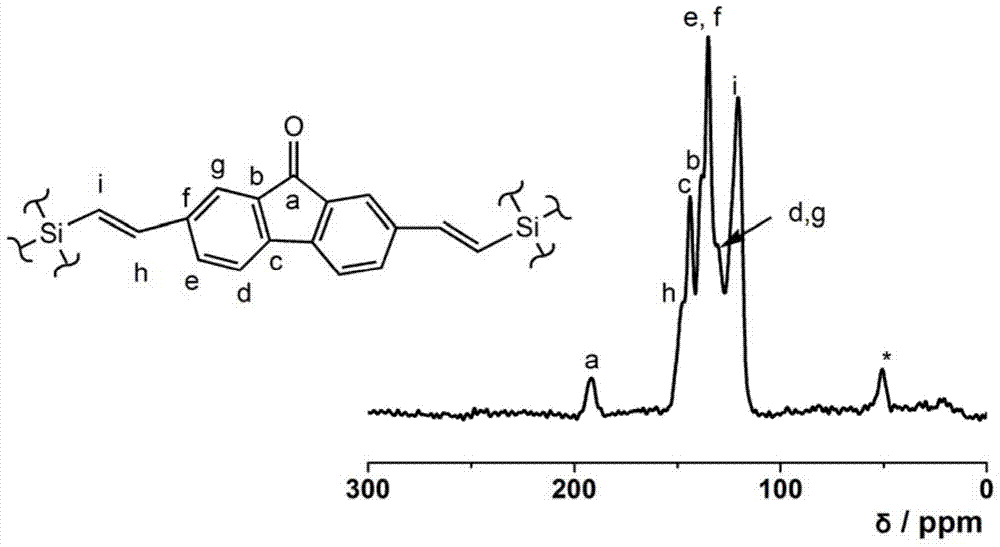

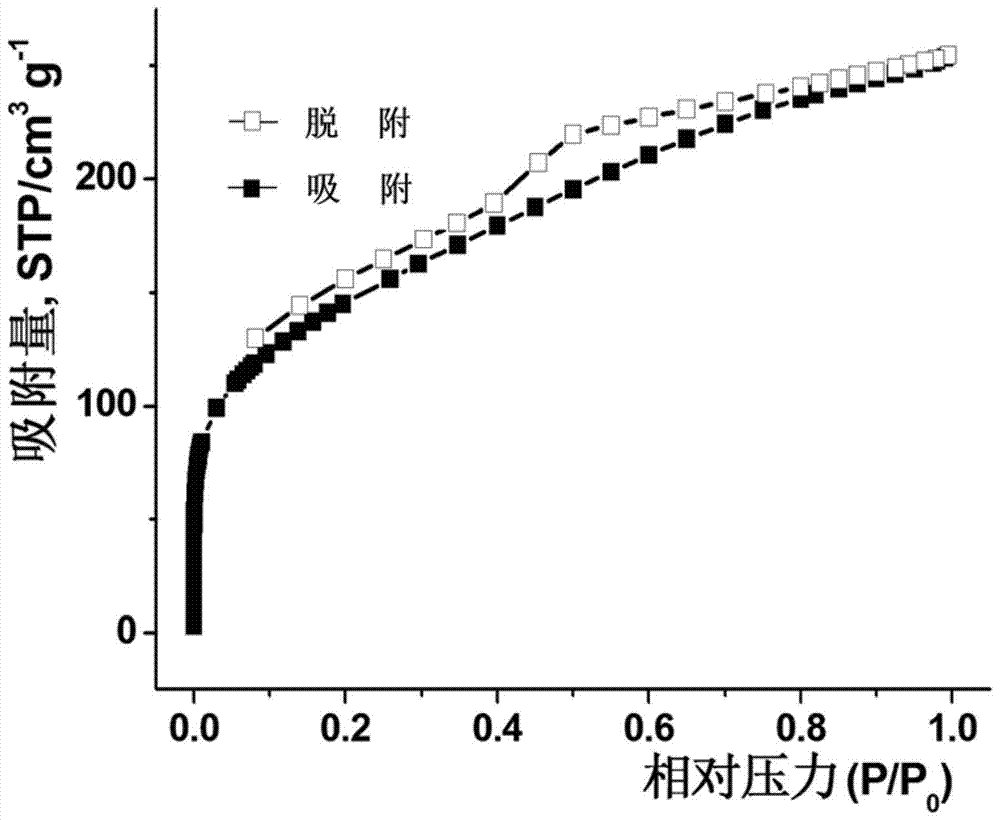

A preparation method of POSS-based porous materials with simultaneously improved porosity and carbon dioxide storage capacity

ActiveCN104558016BLarge specific surface areaHigh pore volumeSilicon organic compoundsOther chemical processesOrganic acidOrganic solvent

The invention relates to a preparation method of a POSS (polyhedral oligomeric silsesquioxane)-based porous material capable of simultaneously improving porosity and carbon dioxide storage volume. The preparation method comprises the following steps: (1) dispersing the POSS-based porous material in an organic solvent, adding a primary amine compound and an organic acid catalyst, and carrying out reflux reaction under a stirring condition for 12-48 hours, wherein the POSS-based porous material comprises a POSS unit and a fluorenone unit, and the primary amine compound at least comprises two amino groups; and (2) after reaction, filtering, washing the filter cake and drying in vacuum to obtain the material. Compared with a raw material POSS-based porous material, the POSS-based porous material prepared by the method has preferable porous performance and carbon dioxide storage performance, and the BET specific surface area, pore volume and carbon dioxide storage volume are improved to a certain extent.

Owner:SHANDONG UNIV

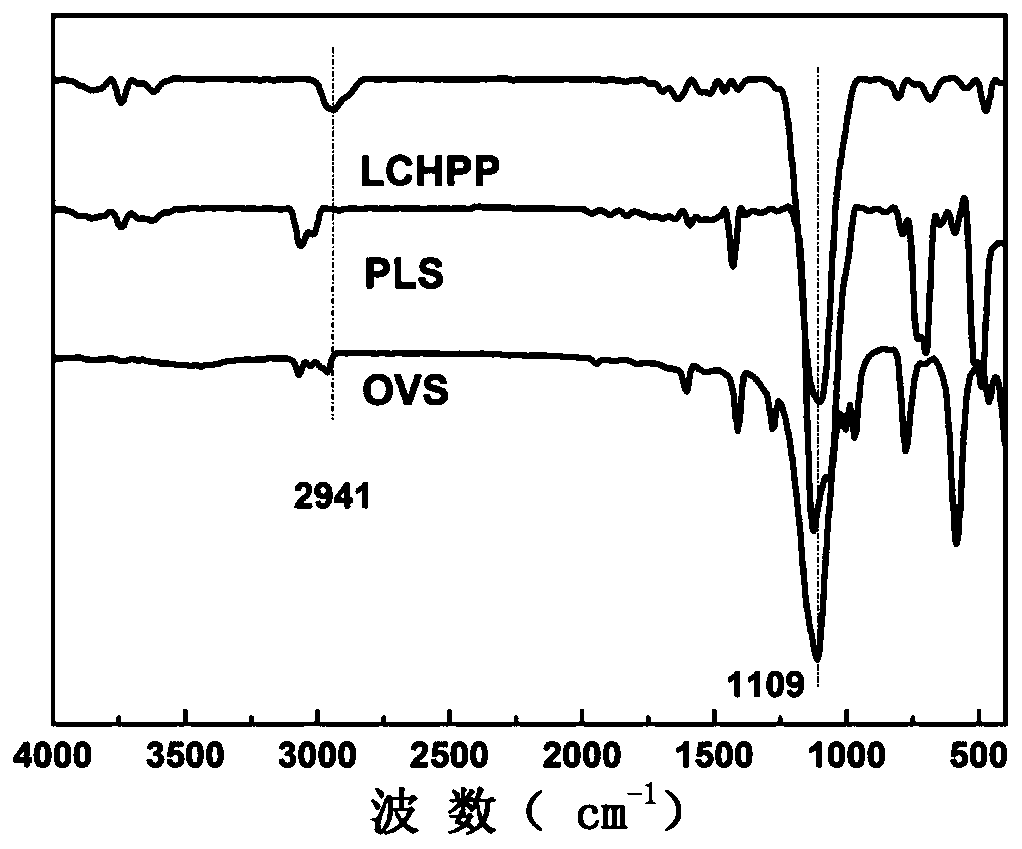

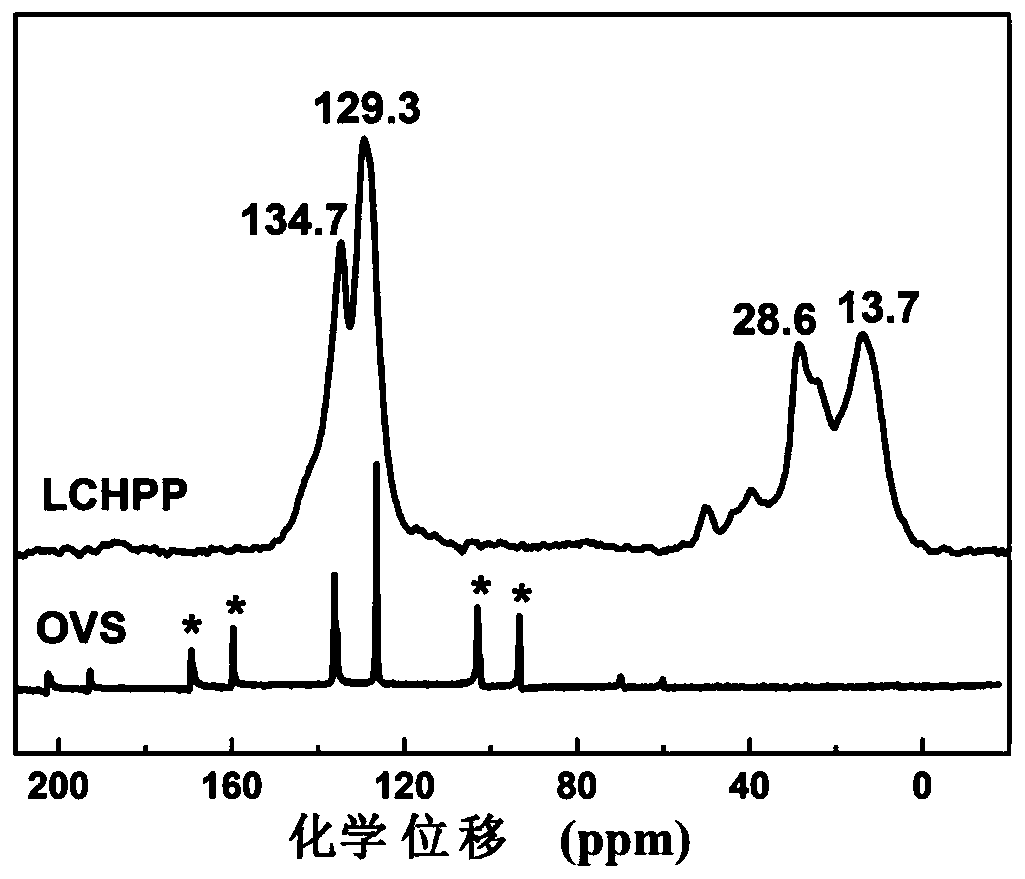

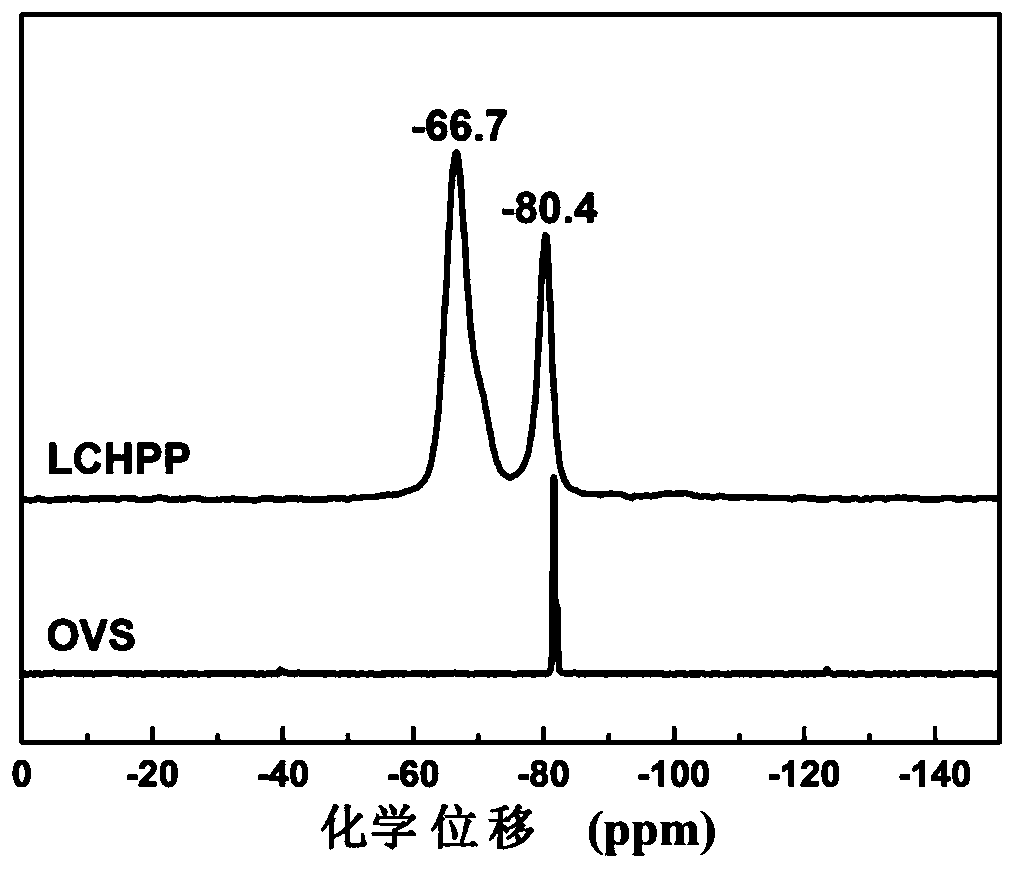

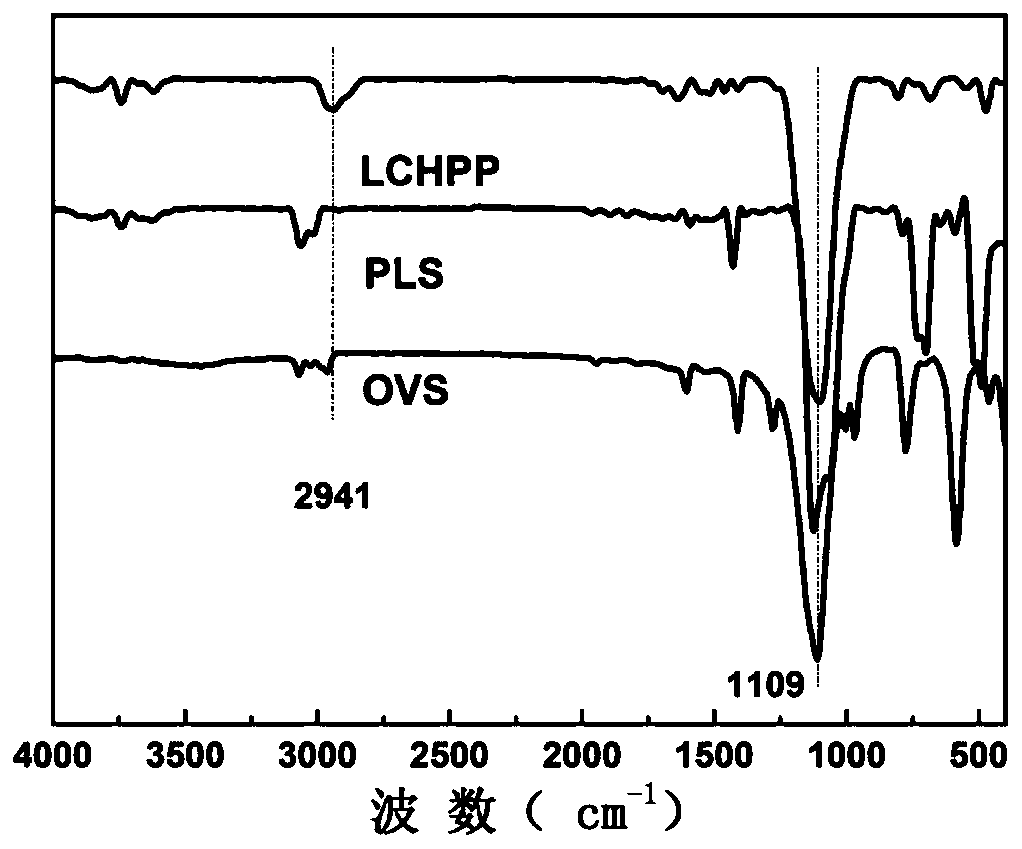

Preparation method of hybrid porous polymer based on cage and ladder type structure silsesquioxane

ActiveCN110452388ASimple preparation stepsThe preparation process conditions are easy to controlWater contaminantsWater/sewage treatment by sorptionIonLarge pore

The invention provides a preparation method of a hybrid porous polymer based on cage and ladder type structure silsesquioxane. The method includes the steps of: dissolving cage structure octavinyl silsesquioxane (OVS) and dodecaphenyl substituted tricyclic trapezoid silsesquioxane (PLS) in an organic solvent, adding a catalyst, stirring the substances uniformly, and carrying out heating reaction;at the end of the reaction, performing cooling to room temperature, filtering and washing to obtain a solid I; subjecting the obtained solid I to soxhlet extraction, and then performing vacuum drying.The preparation steps adopted by the invention are simple, the preparation process conditions are easy to control, and the used raw materials are easily available; the obtained hybrid porous polymerhas high specific surface area, large pore volume, and good chemical stability and thermal stability, and has good adsorption capacity when applied to adsorption of dyes and heavy metal ions.

Owner:SHANDONG UNIV

Moisture-permeable film composite material and preparation method thereof

PendingCN113799465AImprove hydrophilicityImprove performanceLamination ancillary operationsSynthetic resin layered productsPolymer scienceAdhesive

The invention relates to a moisture-permeable film composite material and a preparation method thereof. The moisture-permeable film composite material comprises at least one non-woven fabric layer and a moisture-permeable layer, wherein the moisture-permeable layer and the non-woven fabric layer are bonded with each other; the moisture-permeable layer is prepared from TPEE, an adhesive and other auxiliaries, the content of the TPEE is 88 to 95 percent by weight, the content of the adhesive is 2 to 4 percent by weight, and the content of the other auxiliaries is 0 to 10 percent by weight. The moisture-permeable film composite material has a multi-layer structure and is composed of the non-woven fabric layer and the moisture-permeable layer, the non-woven fabric layer and the moisture-permeable layer form the laminated film composite material, and the moisture-permeable layer forms a layer of film on the surface of the non-woven fabric. Furthermore, the moisture-permeable layer mainly comprises a TPEE material, the TPEE material has non-porous hydrophilic functional groups and can take away sweat gas of a human body and block liquid, and the non-woven fabric has good liquid resistance and surface strength, so that the moisture-permeable film composite material has good moisture permeability while having certain surface strength.

Owner:NAT BRIDGE IND (SHENZHEN) CO LTD

Nano-cellulose flexible iridescent film and preparation method and application thereof

InactiveCN111116994AReduce energy consumptionEasy to operateNano-carbonCellulose treatment using microorganisms/enzymesPolymer scienceMasson pine

The invention discloses a nano-cellulose flexible iridescent film and a preparation method and application thereof, belonging to the field of preparation of functional film materials. The method comprises the following steps: carrying out enzymolysis pretreatment on masson pine pulp; preparing CNF; preparing CNC; preparing CODs; and conducting compounding for film formation. The preparation methodfor film formation is simple in process, controllable in conditions and easy to operate. The CNF, the CNC and the CODs are all from the same initial raw material (namely, the masson pine pulp), so integrated preparation of the flexible film is achieved; and the preparation processes of the three cellulose nanomaterials are simple and easy to operate, mild and friendly reagents are added, and extra chemical reagents are not needed, so environmental friendliness and low energy consumption are achieved, and the concept of sustainable development is met. Therefore, a blending strategy of the CNF,the CNC and the CODs is used for improving the mechanical performance and the optical performance of the iridescent film. The obtained nano-cellulose flexible iridescent film is excellent in performance, and can be applied as a chiral film material to the fields of safety anti-counterfeiting and information encryption.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of artificial cardiovascular and cerebrovascular

ActiveCN108498864BImprove complianceWith simulation designProsthesisTissue reconstructionEngineering

The invention relates to a preparation method of artificial heart and cerebral vessels. The preparation method comprises the following steps: (1) preparing a blood vessel main body structure; (2) performing the biological treatment for the blood vessel main body structure; (3) preparing an intermediate layer on the outer surface of the blood vessel main body structure; (3) and preparing an outermost layer on the outer surface of the intermediate layer. By adopting the preparation method disclosed by the invention, the compliance of the artificial heart and cerebral vessels can be greatly improved, so that the degradation rate of the blood vessels and the tissue reconstruction rate are basically kept consistent, and the mechanical stability of the artificial heart and cerebral vessels can be improved. Meanwhile, the artificial heart and cerebral vessels prepared by the method is good in biological compatibility, high in circulation, simple in preparation, and capable of solving the congestion problem of the heart and cerebral vessels.

Owner:曹磊

Preparation of nanometer granular iron powder

The preparation method of nano particle iron powder includes the following steps: using high-energy ball grinding mill to ball-pulverize pure reduced iron powder whose grain size is 100-200 meshes under the protection of argon, adding quenched stainless steel ball or hard alloy ball in steel tank or hard alloy tank is ball grinding mill and adding a certain quantity of auxiliary additive. Said invention adopts mechanical alloying (high-energy ball-grinding) method to obtain the pure iron powder with higher chemical stability, and its particle size is less than or equal to 100 nano.

Owner:SOUTH CHINA UNIV OF TECH

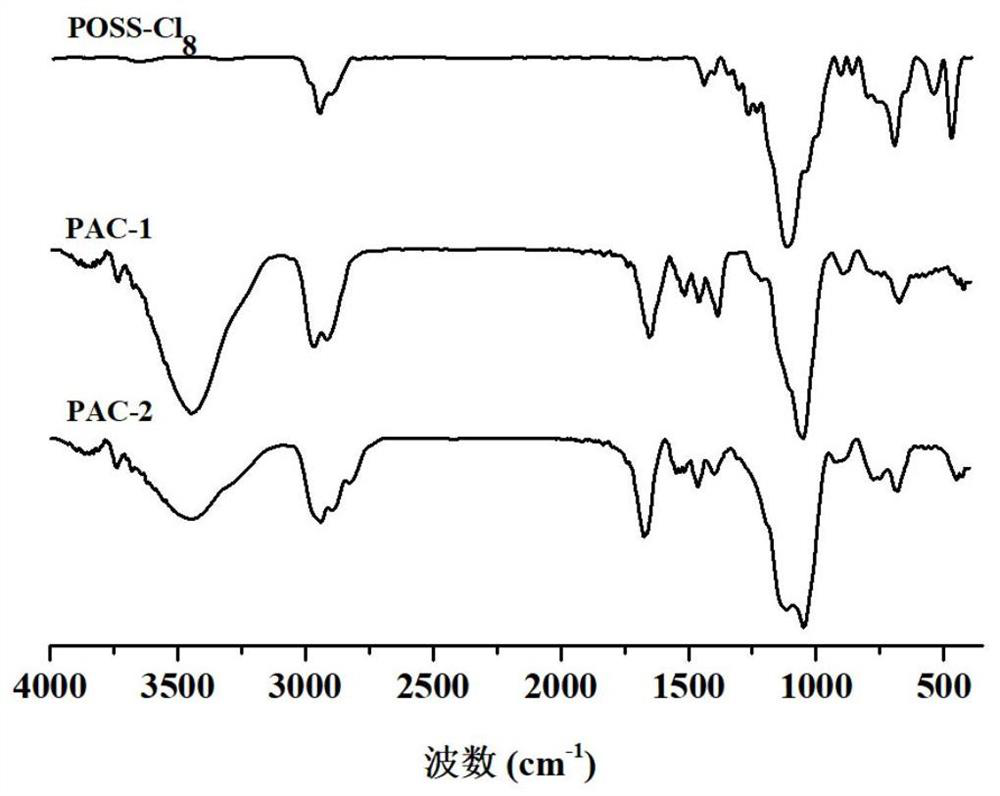

Preparation method of heavy metal ion adsorbent based on amino functionalized silsesquioxane

ActiveCN112657469ASimple preparation stepsThe preparation process conditions are easy to controlOther chemical processesWater contaminantsSodium bicarbonateEthyl group

The invention provides a preparation method of a heavy metal ion adsorbent based on amino functionalized silsesquioxane. The preparation method comprises the following steps: dissolving octachloropropyl silsesquioxane with a cage structure and triaminoethylamine in an organic solvent, adding an acid acceptor, uniformly mixing, and carrying out a heating reaction; after the reaction is finished, cooling to room temperature, filtering and washing to obtain a solid, wherein the acid acceptor is triethylamine or sodium bicarbonate; carrying out Soxhlet extraction on the obtained solid, and then drying to obtain the product. According to the invention, triethylamine or sodium bicarbonate is used as an acid acceptor, and two hybrid network functional material adsorbents with different structures are prepared through nucleophilic substitution reaction; the prepared adsorbent has good chemical stability and thermal stability, the adsorption capacity of the silsesquioxane-based hybrid material to heavy metal ions in wastewater is greatly improved, and the adsorbent has huge potential application value in the field of adsorption.

Owner:SHANDONG UNIV

A kind of fruit wine clarifying agent and preparation method thereof

ActiveCN110624515BImprove adsorption capacityHigh clarityOther chemical processesAlcoholic beverage preparationBiotechnologyAdsorption effect

The invention discloses a fruit wine clarifying agent and a preparation method thereof. The fruit wine clarifying agent consists of 0.01-0.05 g of graphene oxide, 0.4-0.6 g of chitosan, 0.4-0.6 g of sodium alginate, 0.3-0.6 mL of acetic acid solution, Dialdehyde 0.5~1.0mL; ultrapure water 50mL as solvent. The present invention utilizes the composite structure formed by chitosan, graphene oxide and sodium alginate, which has a good adsorption effect on substances that are prone to complex precipitation in fruit wine, and makes the wine body clear and shiny; effectively adsorbs protein, Substances such as metal ions have a good clarification effect and avoid turbidity. At the same time, it can effectively improve the stability of the fruit wine, so that the fruit wine will not be turbid during long-term storage, and the shelf life of the fruit wine is extended.

Owner:LUZHOU LAOJIAO CO LTD +1

A kind of preparation method of modified camellia oil fatliquor for leather processing

ActiveCN106191341BHigh tensile strengthHigh tear strengthLeather impregnationDistillationHydroxyl value

The invention relates to a preparation method for a modified camellia oil fatting agent for leather processing. The method comprises the following steps that a, 850-900 parts by mass of camellia oil, 74-148 parts by mass of n-butyl alcohol and 3-7 parts by mass of catalyzers are taken and added into a reactor; and b, reaction is carried out for 2-3 h at 100-120 DEG C, the hydroxyl value in a reaction system is measured, and by the total amount of reactants, when the hydroxyl value is greater than or equal to 65 mg KOH / g, butyl alcohol which is not fully reacted is removed through reduced pressure distillation.

Owner:JIAXING UNIV

Triazine-functionalized silsesquioxane-based hybrid porous polymer, preparation method and application thereof

ActiveCN112851944BSimple preparation stepsThe preparation process conditions are easy to controlWater/sewage treatment by irradiationWater treatment compoundsTriazineSilsesquioxane

The invention provides triazine functionalized silsesquioxane based hybrid porous polymer, its preparation method and its application in catalytic degradation of dye pollutants. The invention uses octavinylsilsesquioxane (OVS) and triazine monomers (TAs) substituted by bromophenyl or thiophene as raw materials to prepare a hybrid porous material with photocatalytic performance through Heck reaction; the preparation method is simple, The reaction conditions are easy to realize; the obtained material has good chemical stability, thermal stability and fluorescence characteristics, which greatly improves the specific surface area and pore volume of the silsesquioxane-based hybrid porous material, and exhibits high efficiency for dyes in wastewater Catalytic degradation ability has great potential application value in the field of sewage treatment.

Owner:SHANDONG UNIV

A kind of carbazole-based poss monomer and preparation method thereof

Owner:SHANDONG UNIV

Preparation method of artificial heart and cerebral vessels

ActiveCN108498864AImprove complianceWith simulation designProsthesisBlood vessel spasmTissue reconstruction

The invention relates to a preparation method of artificial heart and cerebral vessels. The preparation method comprises the following steps: (1) preparing a blood vessel main body structure; (2) performing the biological treatment for the blood vessel main body structure; (3) preparing an intermediate layer on the outer surface of the blood vessel main body structure; (3) and preparing an outermost layer on the outer surface of the intermediate layer. By adopting the preparation method disclosed by the invention, the compliance of the artificial heart and cerebral vessels can be greatly improved, so that the degradation rate of the blood vessels and the tissue reconstruction rate are basically kept consistent, and the mechanical stability of the artificial heart and cerebral vessels can be improved. Meanwhile, the artificial heart and cerebral vessels prepared by the method is good in biological compatibility, high in circulation, simple in preparation, and capable of solving the congestion problem of the heart and cerebral vessels.

Owner:曹磊

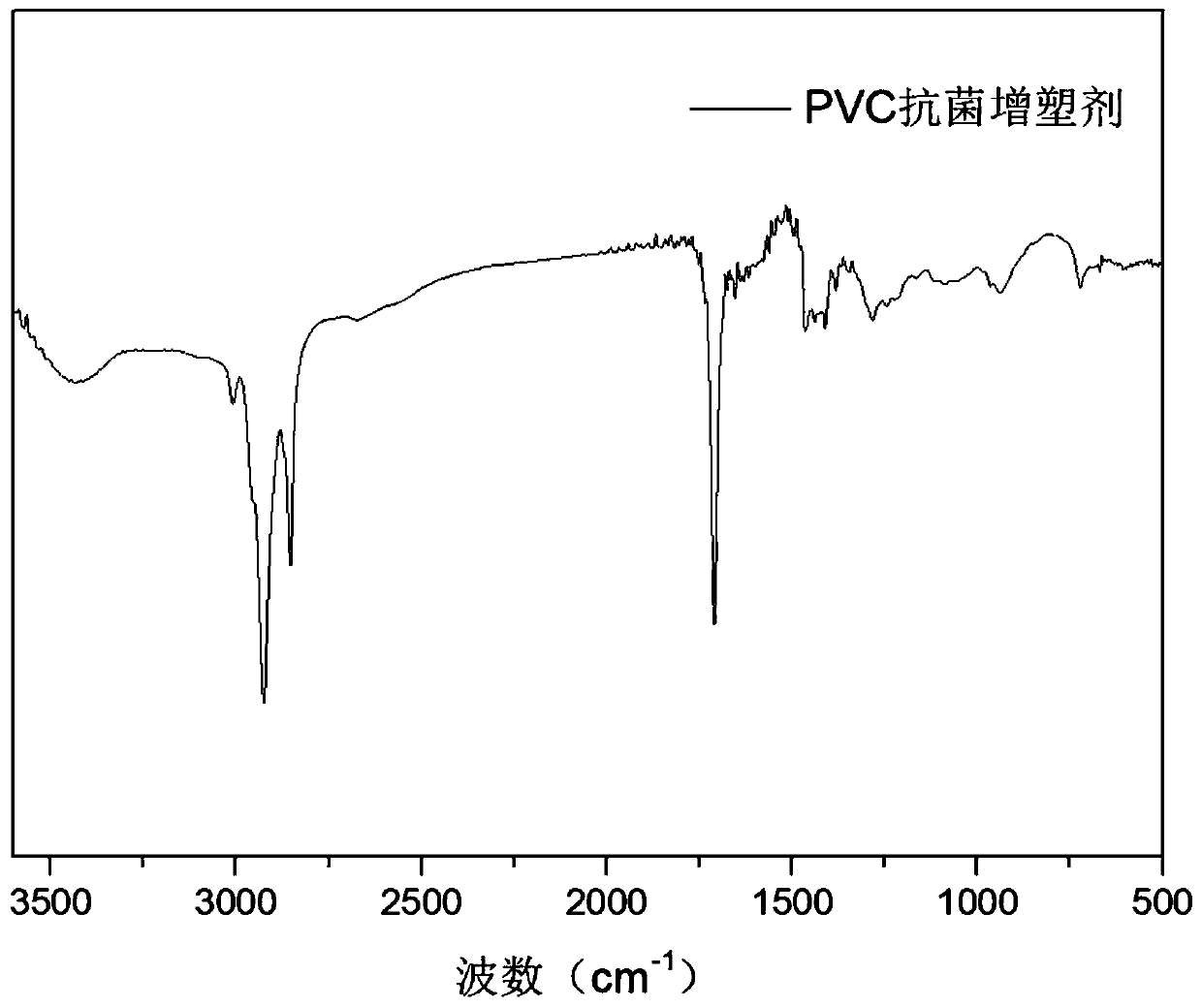

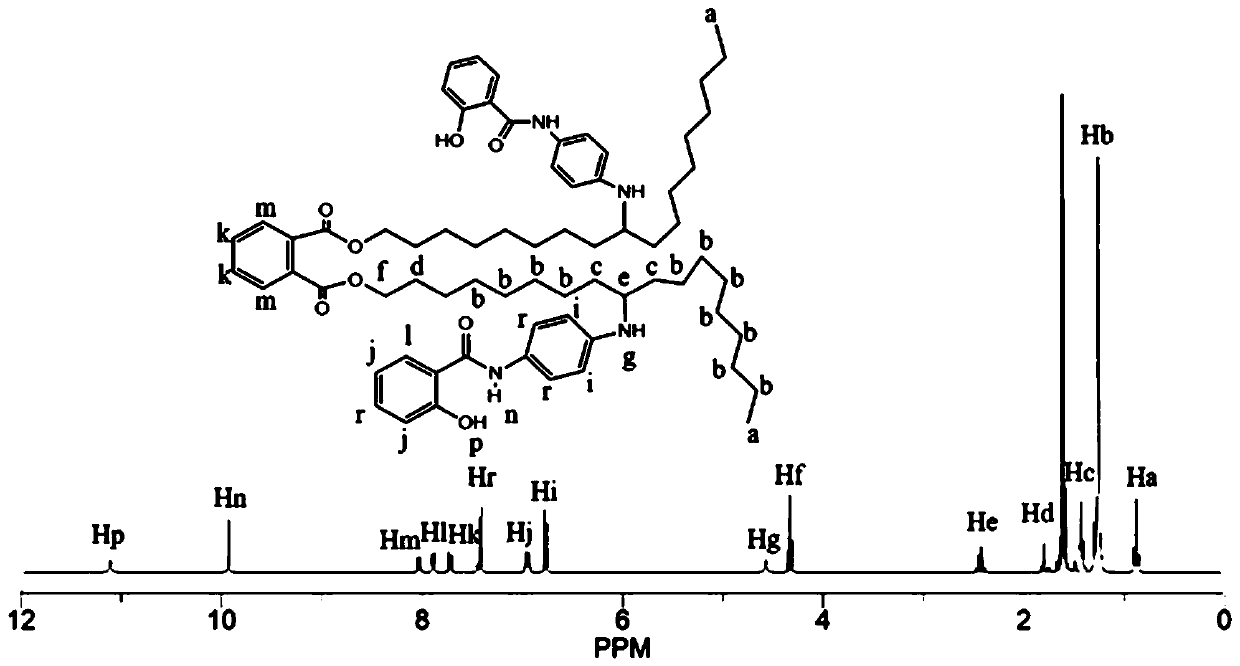

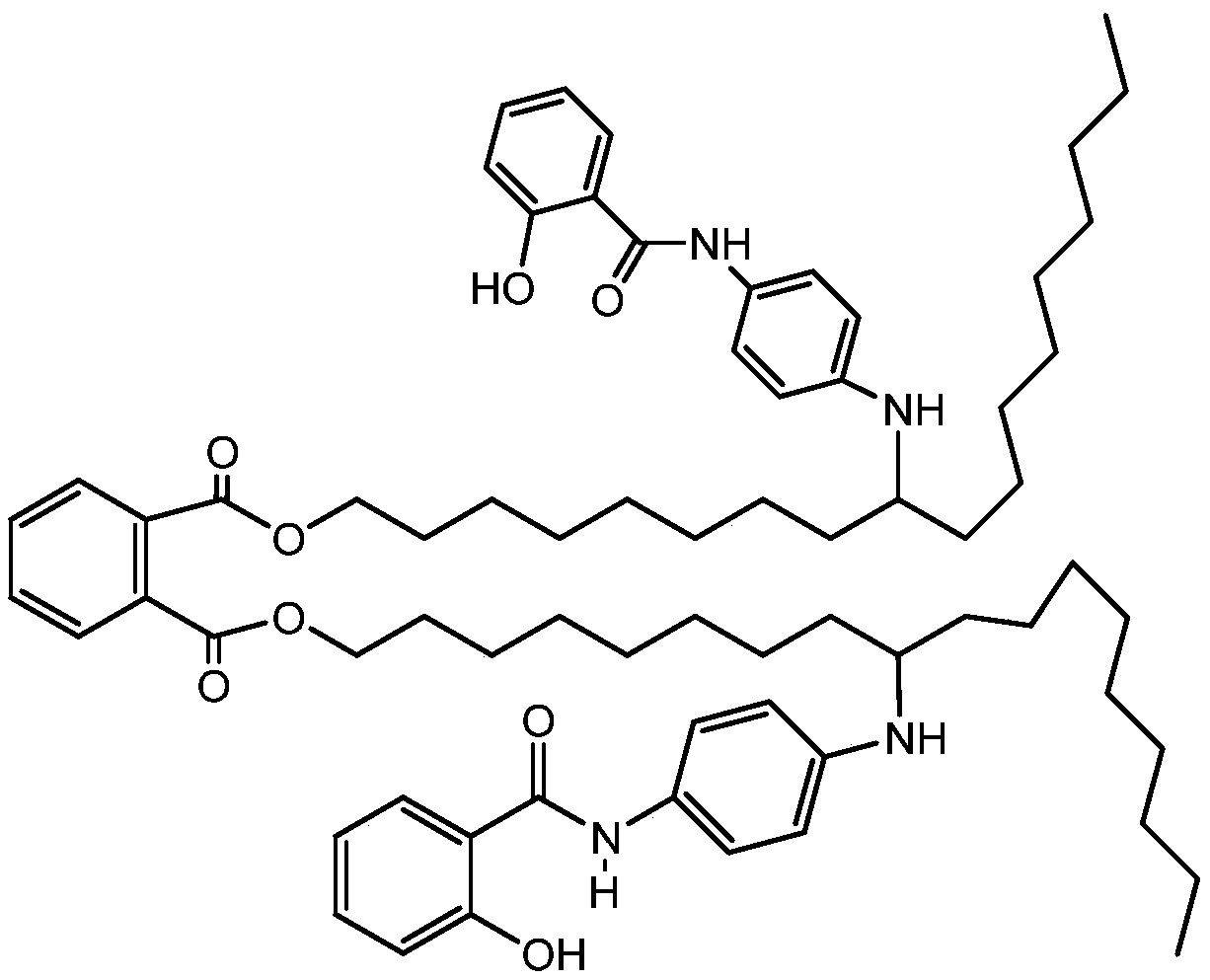

A kind of antibacterial plasticizer for pvc and preparation method thereof

ActiveCN109134927BStrong plasticizing functionImprove antibacterial propertiesPolymer scienceStructural formula

The invention belongs to the field of macromolecular assistants and particularly relates to an antibacterial plastification assistant for PVC and a preparation method thereof. The structural formula of the antibacterial plastification assistant for PVC is shown as the following description. In the structure of the antibacterial plastification assistant prepared by adopting the preparation method,the antibacterial plastification assistant for PVC has a stronger plastification function due to long chains generated through the reaction of phthalic anhydride and oleyl alcohol; contained N-(4-aminophenyl)-2-hydroxyl benzamide has a stronger antibacterial effect, a sterilization spectrum is wider, meanwhile N-H are increased, and the antibacterial effect is better compared with the effect of salicylanilide. The preparation method of the antibacterial plastification assistant for PVC is simple and easy to operate, preparation process conditions are easy to control, the preparation efficiencyis high, the prices of raw materials and the energy consumption of production are both lower, and the antibacterial plastification assistant is very suitable for large-scale production.

Owner:YANGZHOU TIANXI PLASTICS CO LTD

A kind of preparation method of hybrid porous polymer based on cage and ladder structure silsesquioxane

ActiveCN110452388BSimple preparation stepsThe preparation process conditions are easy to controlWater contaminantsWater/sewage treatment by sorptionPtru catalystOrganosolv

The invention provides a preparation method of a hybrid porous polymer based on cage and ladder type structure silsesquioxane. The method includes the steps of: dissolving cage structure octavinyl silsesquioxane (OVS) and dodecaphenyl substituted tricyclic trapezoid silsesquioxane (PLS) in an organic solvent, adding a catalyst, stirring the substances uniformly, and carrying out heating reaction;at the end of the reaction, performing cooling to room temperature, filtering and washing to obtain a solid I; subjecting the obtained solid I to soxhlet extraction, and then performing vacuum drying.The preparation steps adopted by the invention are simple, the preparation process conditions are easy to control, and the used raw materials are easily available; the obtained hybrid porous polymerhas high specific surface area, large pore volume, and good chemical stability and thermal stability, and has good adsorption capacity when applied to adsorption of dyes and heavy metal ions.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com