Environment-friendly asphalt mixture and preparation method thereof

An asphalt mixture and an environment-friendly technology, applied in the field of environment-friendly asphalt mixture and its preparation, can solve the problems of low Marshall stability, high water absorption, weak aggregate bearing capacity, etc., and achieve the preparation process conditions that are easy to control and improve the resistance to The effect of cracking performance and strengthening connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

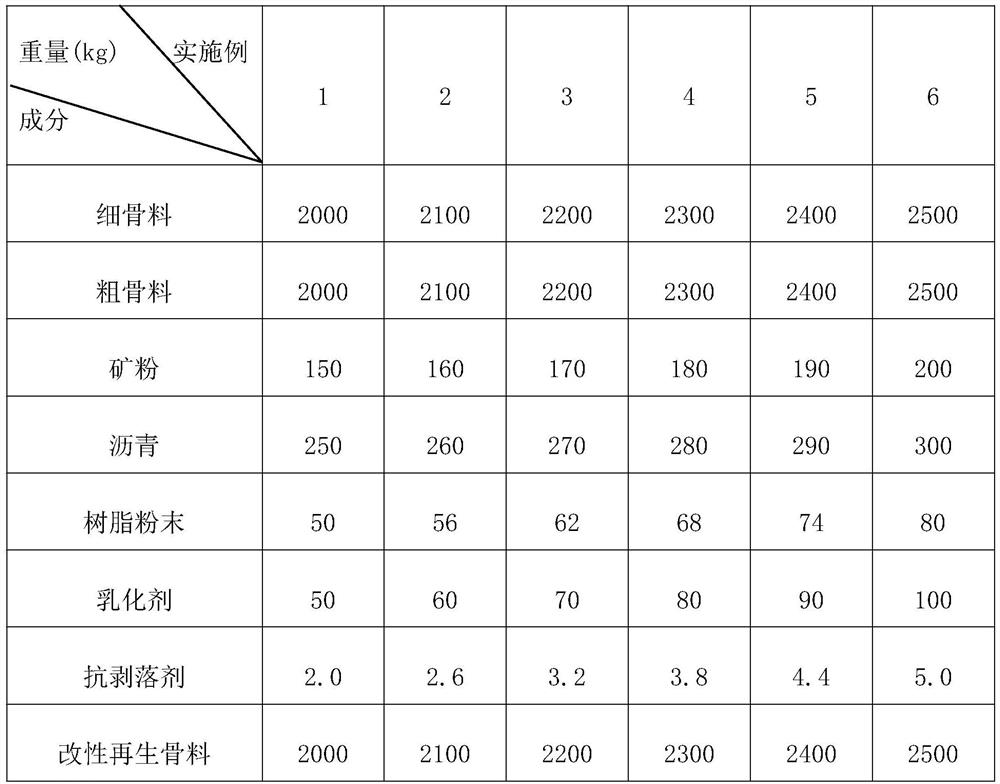

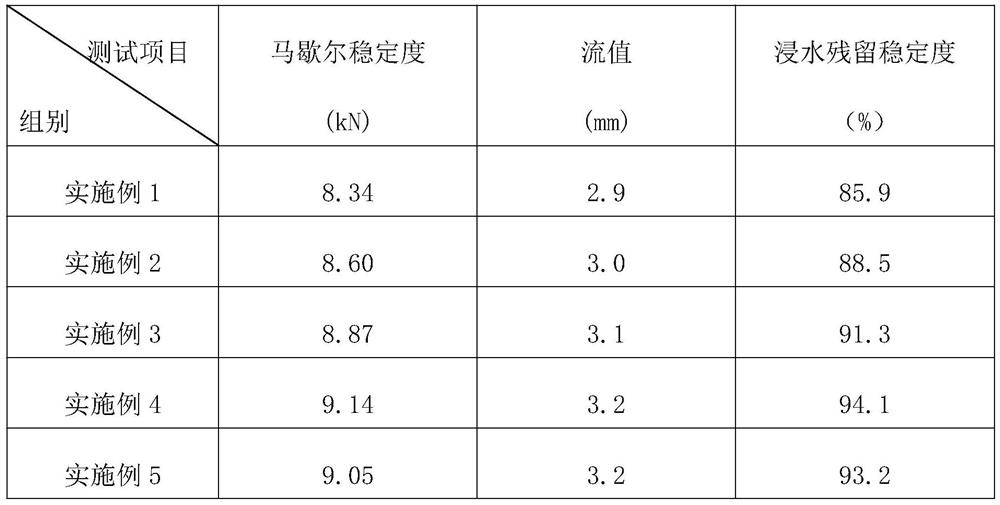

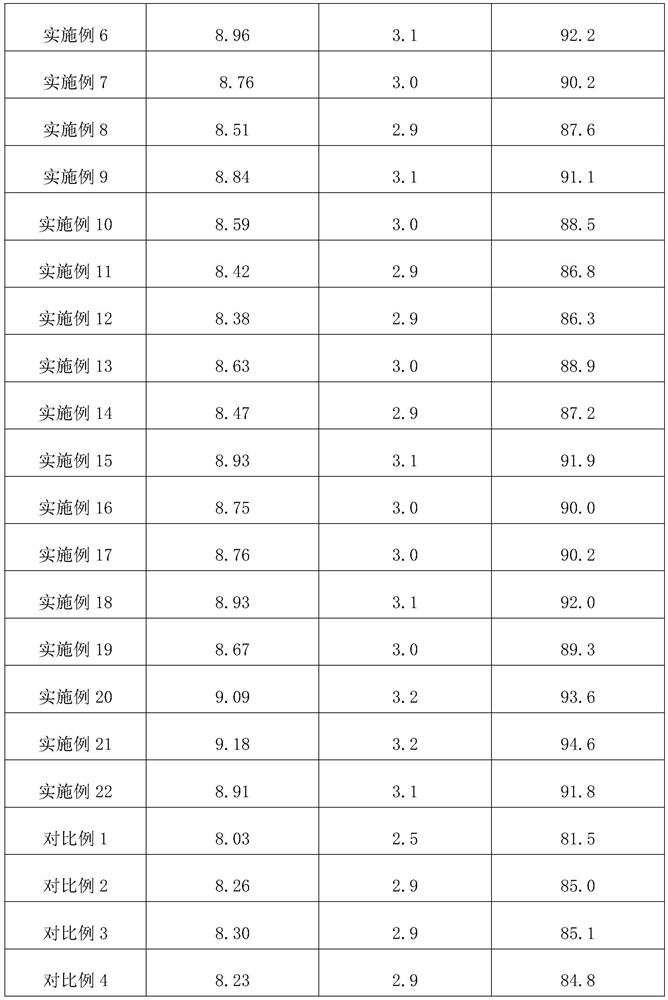

Method used

Image

Examples

preparation example 1

[0071] A modified recycled aggregate is prepared by the following steps:

[0072] a. First, heat the waste concrete blocks to 600°C, pass in high-pressure air, and after cooling to room temperature, put them into a ball mill for crushing and grinding, and sieve the crushed powder with a particle size of less than 10mm for later use;

[0073] b. Put the crushed powder prepared in a into a hot stirring tank with pickling solution, heat and stir at 200r / min at 60°C for 2 hours, then take it out and dry it for later use;

[0074] The pickling solution is composed of phosphoric acid, oxalic acid, and hydrochloric acid in a volume ratio of 1:0.5:0.2, and the pH of the pickling solution is 5.0;

[0075] c. Put the crushed powder after pickling in b into a hot stirring tank equipped with alkalization solution, feed nitrogen gas, stir for 4 hours at a speed of 200r / min, take it out and dry it for later use;

[0076] The alkaline solution is composed of water, ethanol, sodium hydroxide...

preparation example 2

[0081] a. First, heat the waste concrete blocks to 700°C, pass in high-pressure air, and after air cooling to room temperature, put them into a ball mill for crushing and grinding, and sieve the crushed powder with a particle size of less than 10mm for later use;

[0082] b. Put the crushed powder prepared in a into a hot stirring tank with pickling solution, heat and stir at 300r / min at a temperature of 70°C for 3 hours, then take it out and dry it for later use;

[0083] The pickling solution is composed of phosphoric acid, oxalic acid, and hydrochloric acid in a volume ratio of 1:0.5:0.2, and the pH of the pickling solution is 3.0;

[0084] c. Put the crushed powder after pickling in b into a hot stirring tank equipped with alkalization solution, feed nitrogen gas, stir for 6 hours at a speed of 300r / min, take it out and dry it for later use;

[0085] The alkaline solution is composed of water, ethanol, sodium hydroxide, sodium silicate, and calcium hydroxide in a weight ra...

preparation example 3

[0090] a. First, heat the waste concrete blocks to 800°C, pass in high-pressure air, and after cooling to room temperature, put them into a ball mill for crushing and grinding, and sieve the crushed powder with a particle size of less than 10mm for later use;

[0091] b. Put the pulverized powder prepared in a into a heated stirring tank with pickling solution, heat and stir at 400r / min at 80°C for 4 hours, then take it out and dry it for later use;

[0092] The pickling solution is composed of phosphoric acid, oxalic acid, and hydrochloric acid in a volume ratio of 1:0.5:0.2, and the pH of the pickling solution is 5.0;

[0093] c. Put the crushed powder after pickling in b into a hot stirring tank equipped with an alkalization solution, feed in nitrogen, stir at a speed of 400r / min for 8 hours, take it out and dry it for later use;

[0094] The alkaline solution is composed of water, ethanol, sodium hydroxide, sodium silicate, and calcium hydroxide in a weight ratio of 1:0.2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com