A kind of antibacterial plasticizer for pvc and preparation method thereof

A technology of plasticizing additives and solvents, which is applied in the field of antibacterial plasticizing additives for PVC and its preparation, can solve the problems that polyvinyl chloride does not have antibacterial properties, limits the application range of polyvinyl chloride, breeds bacteria and harmful microorganisms, etc., and achieves The effects of wide sterilization spectrum, free volume increase and control of preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

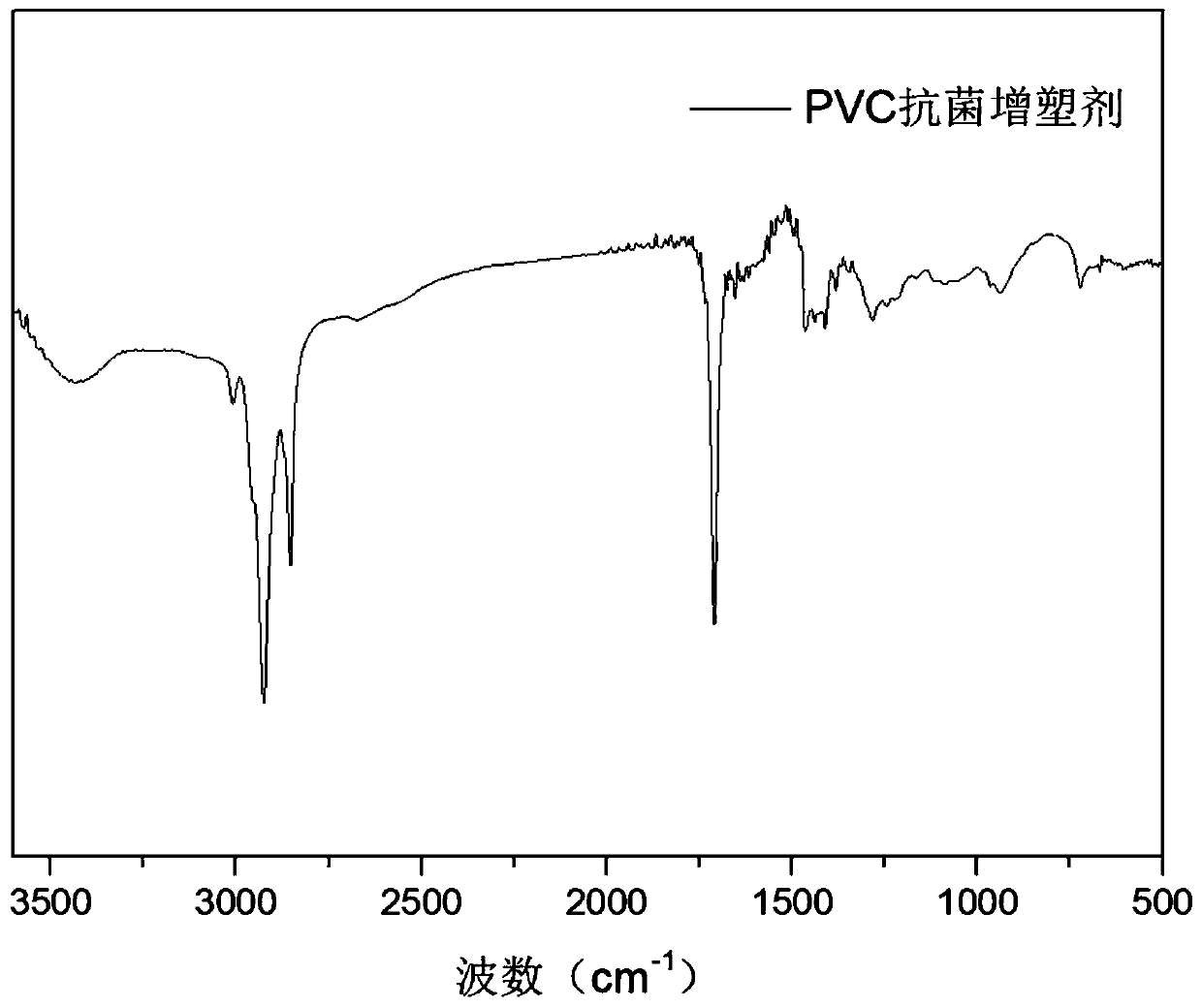

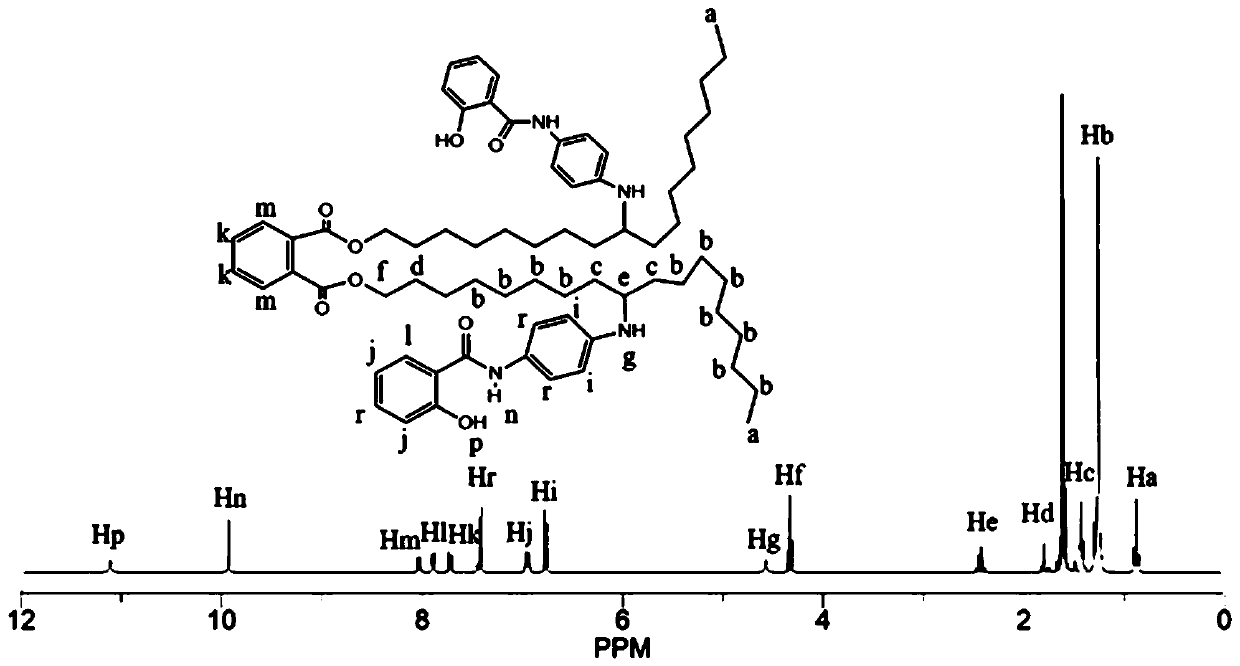

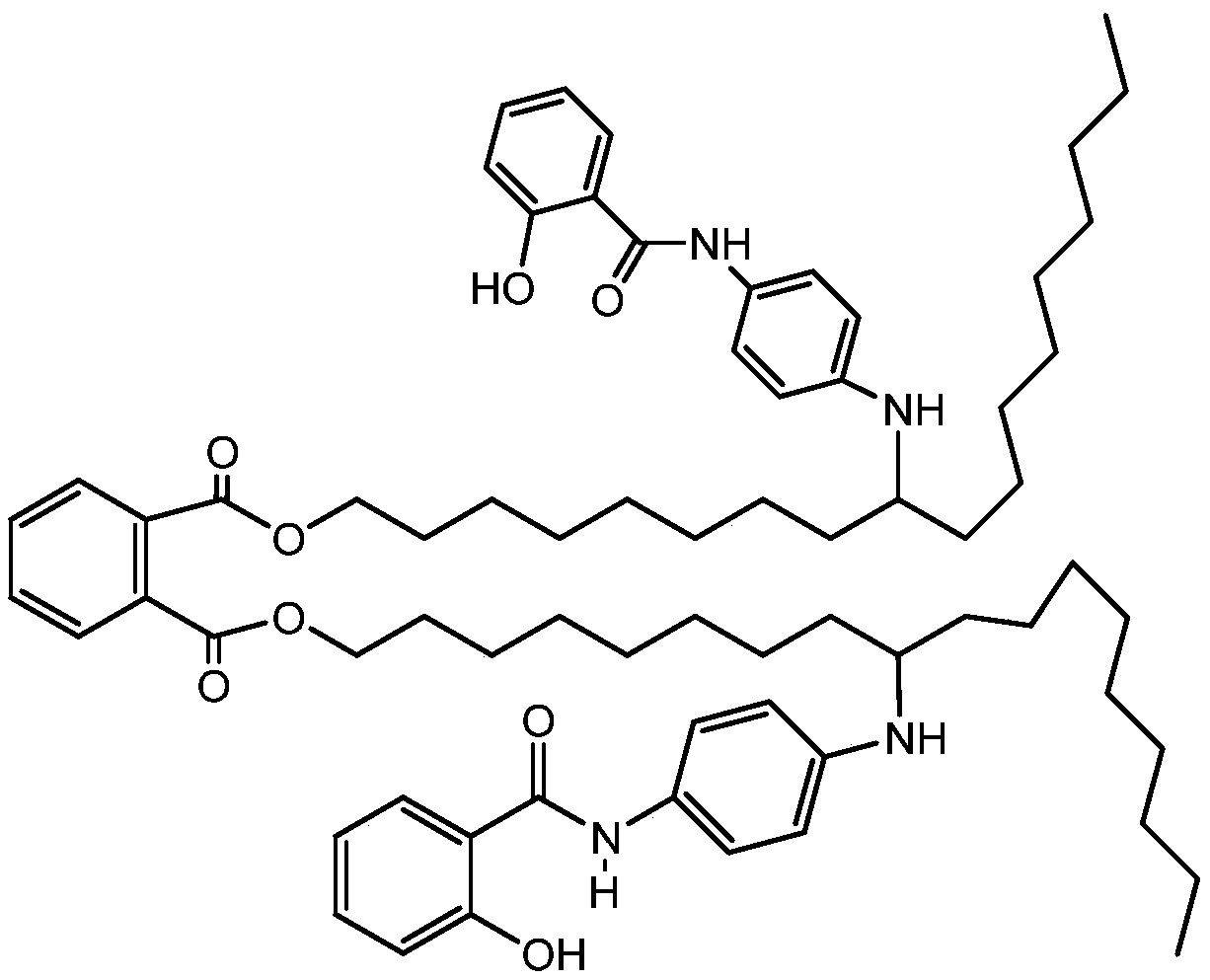

Image

Examples

Embodiment 1

[0028] A kind of synthetic steps of antibacterial plasticizing auxiliary agent for PVC is:

[0029] (1) Add 14.8g of phthalic anhydride and 80.5g of oleyl alcohol into a dry four-necked flask equipped with a water separator, a thermometer and a reflux condenser, mix well, heat up to 65°C, and add 1.9g of concentrated sulfuric acid and 1g of p-hydroxy Anisole, after the phthalic anhydride melts, heat up to 90°C, continue to stir for 4 hours, cool to room temperature, extract the product with ethyl acetate, wash with water 2 to 3 times, filter, dry, and distill off the solvent under reduced pressure to obtain intermediate product;

[0030] (2) Under inert gas protection conditions, add 66.7g of the intermediate product of step (1) into a four-necked flask, then add its 133.4g N'N-dimethylformamide, stir and mix evenly, then add 2.7g of carbonic acid Potassium and 1.4g p-hydroxyanisole, stirred at room temperature for 1h, then heated to 70°C, dissolved 67.9g N-(4-aminophenyl)-2-...

Embodiment 2

[0035] A kind of synthetic steps of antibacterial plasticizing auxiliary agent for PVC is:

[0036](1) Add 14.8g of phthalic anhydride and 94g of oleyl alcohol into a dry four-necked flask equipped with a water separator, a thermometer and a reflux condenser, mix well, heat up to 60°C, and add 3.3g of p-toluenesulfonic acid and 2.2g of For p-hydroxyanisole, after the phthalic anhydride melts, heat up to 88°C, continue to stir for 5 hours, then cool to room temperature, extract the product with ethyl acetate, wash with water 2 to 3 times, filter, dry, and distill under reduced pressure to remove the solvent. get intermediate products;

[0037] (2) Under the protection condition of inert gas, the intermediate product of 66.7g step (1) is joined in the four-necked flask, then add its 200g methylene chloride, stir and mix evenly, then add 4.7g sodium ethylate and 3.2g p-hydroxybenzene Methyl ether, stirred at room temperature for 2h, then raised the temperature to 70°C, dissolved...

Embodiment 3

[0039] A kind of synthetic steps of antibacterial plasticizing auxiliary agent for PVC is:

[0040] (1) Add 14.8g of phthalic anhydride and 107.4g of oleyl alcohol into a dry four-neck flask equipped with a water separator, a thermometer and a reflux condenser, mix well, heat up to 70°C, and add 4.9g of methanesulfonic acid and 1.8g of Hydroquinone, after the phthalic anhydride melts, heat up to 85°C, continue to stir for 6 hours, cool to room temperature, extract the product with ethyl acetate, wash with water 2 to 3 times, filter, dry, and distill off the solvent under reduced pressure to obtain mid product;

[0041] (2) Under inert gas protection conditions, the intermediate product of 66.7g step (1) is joined in the four-necked flask, then adds its 266.8g toluene, stirs and mixes evenly, then adds 5.8g potassium carbonate and 2.2g hydroquinone , stirred at room temperature for 2h, then raised the temperature to 70°C, dissolved 80g of N-(4-aminophenyl)-2-hydroxybenzamide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com