Hyaluronic acid mixed gel containing amphiphilic microspheres for injection and preparation method thereof

A technology of amphiphilic microspheres and hyaluronic acid, which is applied in the field of hyaluronic acid mixed gel and its preparation, can solve the problems of uniform dispersion of hyaluronic acid gel, poor hydrophilicity of polylactic acid microspheres, and non-hydrophilicity of polylactic acid, etc. problem, to achieve the effect that the preparation process conditions are easy to control, the plasticity is good, and the effect is natural and gradual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

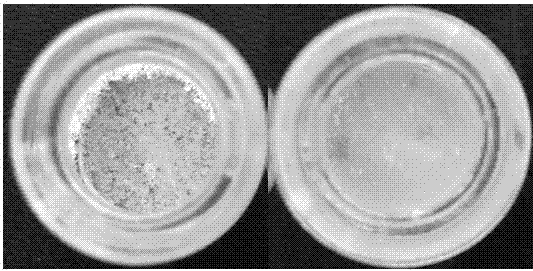

Image

Examples

Embodiment 1

[0028] (1) Dissolve 8 g of PLGA with a molecular weight of 120,000 and LA / GA=90 / 10 in 80 mL of dichloromethane, and then add it dropwise to 160 mL of 2% polyvinyl alcohol aqueous solution at a rate of 50-60 drops / min, after the addition is complete, stir at room temperature for 1 hour, heat up to 45°C, remove dichloromethane to obtain a reaction solution, filter the reaction solution to collect the filter cake, and sieve out 5 g of microspheres of 25-45 μm.

[0029] (2) Dissolve 0.4 g of hyaluronic acid in 2 mL of water for injection, add 0.2 mL of 20% sodium hydroxide solution, add 15 μL of 1,4-butanediol diglycidyl ether, add 4 mL of 2.6 mol / L hydrochloric acid to adjust the pH to 6.5-7.5, then add 7 mL of 1% lidocaine hydrochloride, and then add 5 mL of PBS buffer solution to adjust the osmotic pressure to 250-350 mOsm / L to obtain a gel, and the mass fraction of hyaluronic acid is 20 mL of 20% gel.

[0030] (3) Add 5 g of PLGA microspheres prepared by the above method into...

Embodiment 2

[0032] (1) 10 g of PLLA-PEG with a molecular weight of 141,000, in which PLLA with a molecular weight of 140,000 and PEG with a molecular weight of 1,000, was dissolved in 100 mL of dichloromethane, and then added dropwise to 200 mL of 2% polyvinyl alcohol aqueous solution , the dropping rate is 50-60 drops / min, after the addition is completed, stir at room temperature for 1 hour, heat up to 45°C, remove dichloromethane to obtain the reaction solution, filter the reaction solution to collect the filter cake, and sieve out 6 g of 25-45 μm of microspheres.

[0033] (2) Dissolve 0.4 g of hyaluronic acid in 2 mL of water for injection, add 0.2 mL of 20% sodium hydroxide solution, add 15 μL of 1,4-butanediol diglycidyl ether, add 4 mL of 2.6 mol / L hydrochloric acid to adjust the pH to 6.5-7.5, then add 7 mL of 1% lidocaine hydrochloride, and then add 5 mL of PBS buffer solution to adjust the osmotic pressure to 250-350 mOsm / L to obtain a gel, and the mass fraction of hyaluronic aci...

Embodiment 3

[0036] (1) 20 g of PLGA-PEG with a molecular weight of 100,000, in which PLGA molecular weight is 99,000, LA / GA=70 / 30. PEG molecular weight is 5,000, is dissolved in 200 mL of dichloromethane, and then added dropwise to 400 mL of mass In the polyvinyl alcohol aqueous solution with a fraction of 2%, the dropping rate is 50-60 drops / min. After the dropping is completed, stir at room temperature for 2 hours, then raise the temperature to 45°C, remove the dichloromethane to obtain the reaction solution, filter the reaction solution to collect the filter cake, sieve 9 g of microspheres of 25-45 μm were separated.

[0037](2) Dissolve 0.4 g of hyaluronic acid in 2 mL of water for injection, add 0.2 mL of 20% sodium hydroxide solution, add 15 μL of 1,4-butanediol diglycidyl ether, add 4 mL of 2.6 mol / L hydrochloric acid to adjust the pH to 6.5-7.5, then add 7 mL of 1% lidocaine hydrochloride, and then add 5 mL of PBS buffer solution to adjust the osmotic pressure to 250-350 mOsm / L to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com